Installation – Ramsey Winch REP-8000e User Manual

Page 4

Installation

The winches shown in this owner's manual are solely and

exclusively designed for vehicle mounted, non-industrial appli-

cations. All other applications will void warranty.

Note: For specific bull-bar applications, the shifter lever on

the winch may need to be repositioned. Refer to pages 5-6 for

instructions on how to do this.

It is very important that the winch be mounted on a flat sur-

face so that the three major sections (the motor end, the cable

drum and the gear housing end) are properly aligned. It is rec-

ommended that Ramsey kits be used to mount the winch.

They are designed to align the winch and distribute up to the

full rated load evenly, to avoid possible damage to the winch

or vehicle. Note: If recommended mounting is not used, a kit

of equal design must be used.

Also available for mounting the REP 8000e winch are the fol-

lowing winch mounting channels:

#408052 Short length (23.63" black)

#408120 Medium length (30.00" black)

#408101 Long length (36.00" black)

It is recommended that a Ramsey mounting channel be used

in all non-Ramsey mountings.

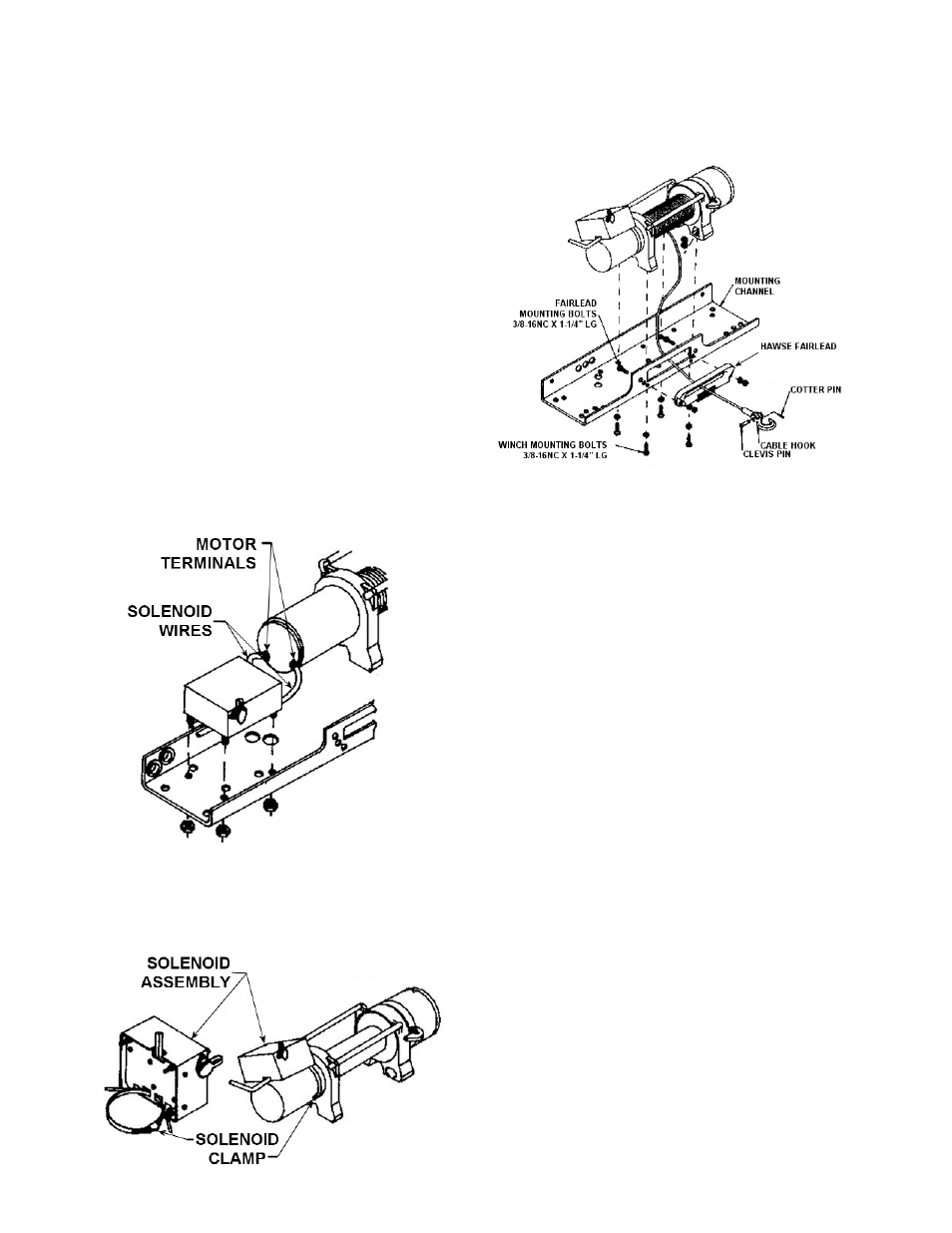

When mounting winch, attach solenoid wires to motor termi-

nals at end of motor. TIGHTEN NUTS ON MOTOR TERMINALS

SECURELY (see FIGURE 1). Attach solenoid to mounting holes

at end of long channel (see FIGURE 1) or use solenoid clamp

to attach solenoid assembly to winch motor (see FIGURE 2).

Position solenoid at about a 45° angle so that it clears lower

winch guard tube of mounting kit. TIGHTEN CLAMP SECURE-

LY.

Attach fairlead to channel using hardware furnished with winch

(see FIGURE 3). Attach winch to channel. Place (4) flat wash-

ers and nuts into pockets of winch mounting feet and thread

capscrews with lock washers through mounting holes in chan-

nel and into hardware in winch feet.

Substitution of attaching hardware items (bolts, nuts or wash-

ers) different from those supplied with your winch and mount-

ing kit can lead to failure causing damage or serious injury

(use SAE grade 5 bolts or better and torque to 34 ft. lbs.)

Place end of drum cable through fairlead and attach cable

hook. Use clevis pin and cotter pin (see FIGURE 3).

FIGURE 1

FIGURE 2

FIGURE 3

4