Ramsey Winch REP-6000/8000/9000 CURRENT User Manual

Page 5

REP 9000 24V

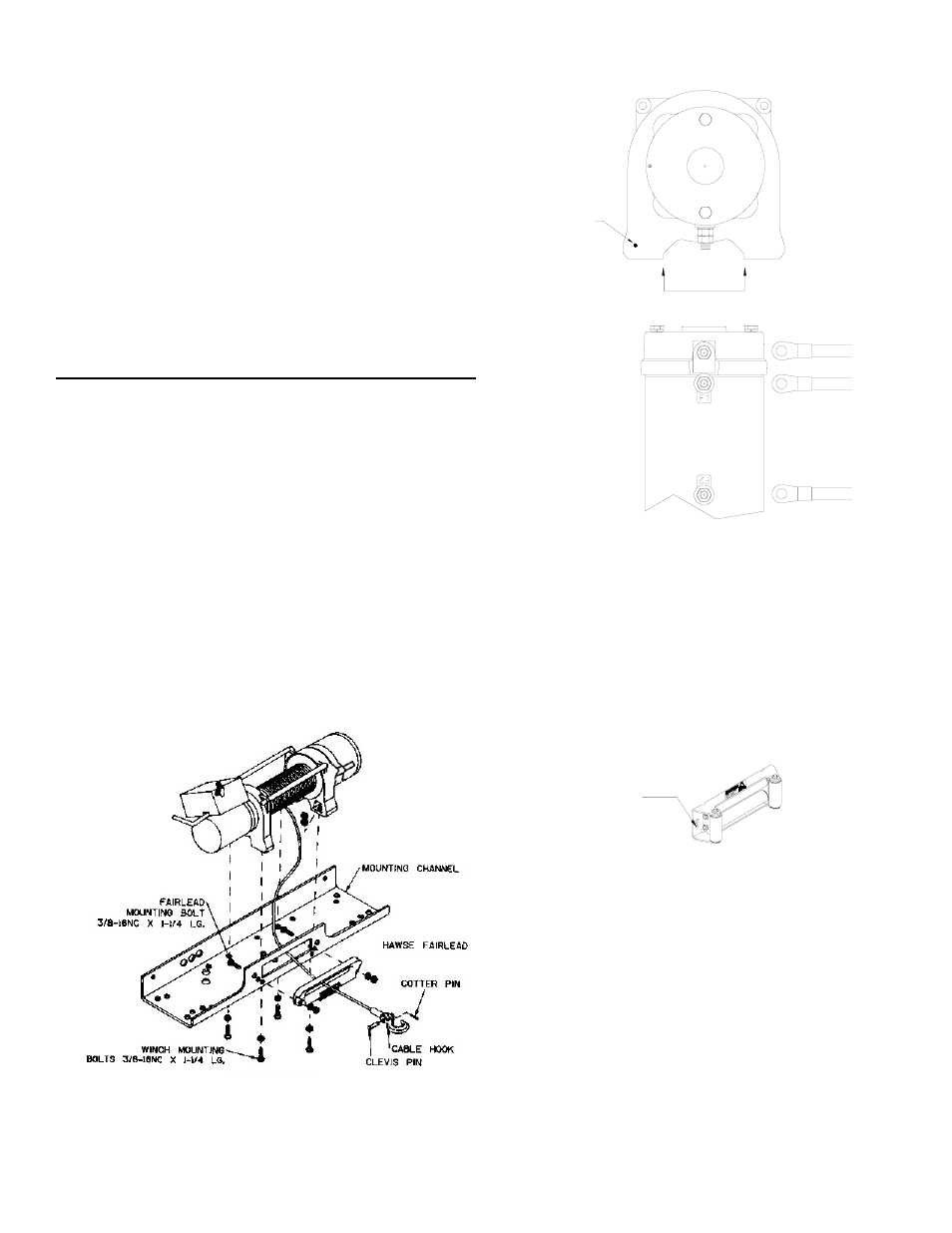

When mounting winch, connect labeled motor leads com-

ing from solenoid assembly to appropriately marked

motor terminals as shown in FIGURE 4. TIGHTEN NUTS

ON MOTOR TERMINALS. Attach solenoid ground to #10

Capscrew located on vertical surface of motor end bear-

ing (See FIGURE 4). Use solenoid clamp, as shown in

FIGURE 1, to secure solenoid assembly to winch motor. If

installing in combo mounting kit, position at about a 45°

angle for clearance of lower winch guard tube in kit. Be

sure that clamp is clear of motor terminals at bottom of

motor. TIGHTEN CLAMP SECURELY.

Attach fairlead to channel using hardware furnished with

winch (see FIGURE 5). Attach winch to channel. Place (4)

flat washers and nuts into pockets of winch mounting feet

and thread capscrews with lock washers through mount-

ing holes in channel and into hardware in winch feet.

Substitution of attaching hardware items (bolts, nuts or

washers) different from those supplied with your winch

and mounting kit can lead to failure causing damage or

serious injury (use SAE grade 5 bolts or better and torque

to 34 ft. lbs.)

Place end of drum cable through fairlead and attach cable

hook. Use clevis pin and cotter pin (see FIGURE 5).

5

FIGURE 5

DETAIL A

ROLLER FAIRLEAD

OF THE ROLLER FAIRLEAD TO THE

OF HOLES AT BOTTOM FOR MOUNTING

DRUM, POSITION SMALLER (7/16") SET

TO ENSURE PROPER ALIGNMENT

Hole for Solenoid

Ground Wire Bolt

A

A

View A-A

A

1

2

FIGURE 4

REP 9000 24v