Installation – Ramsey Winch REP-6000/8000/9000 CURRENT User Manual

Page 4

Installation

The winches shown in this owner's manual are solely

and exclusively designed for vehicle mounted, non-

industrial applications. All other applications will void

warranty.

Note: For specific bull-bar applications, the shifter lever

on the winch may need to be repositioned. Refer to

pages 7-8 for instructions in how to do this.

It is very important that the winch be mounted on a flat

surface so that the three major sections (the motor end,

the cable drum and the gear housing end) are properly

aligned. It is recommended that Ramsey kits be used to

mount the winch. They are designed to align the winch

and distribute up to the full rated load evenly, to avoid

possible damage to the winch or vehicle. Note: If recom-

mended mounting is not used, a kit of equal design must

be used.

Also available for mounting the REP winches are winch

mounting channels, short length (23.63") #408052

(black), medium length (30.00") #408120 (black) and

long length (36.00") #408101 (black). It is recommend-

ed that a Ramsey mounting channel be used in all non-

Ramsey mountings.

Note: See the following separate sections for attaching

the wiring to the motor and solenoid for the REP 6000,

and REP 8000 and REP 9000 12V and 24V models. The

combined installation instructions resume on the follow-

ing page.

REP 6000

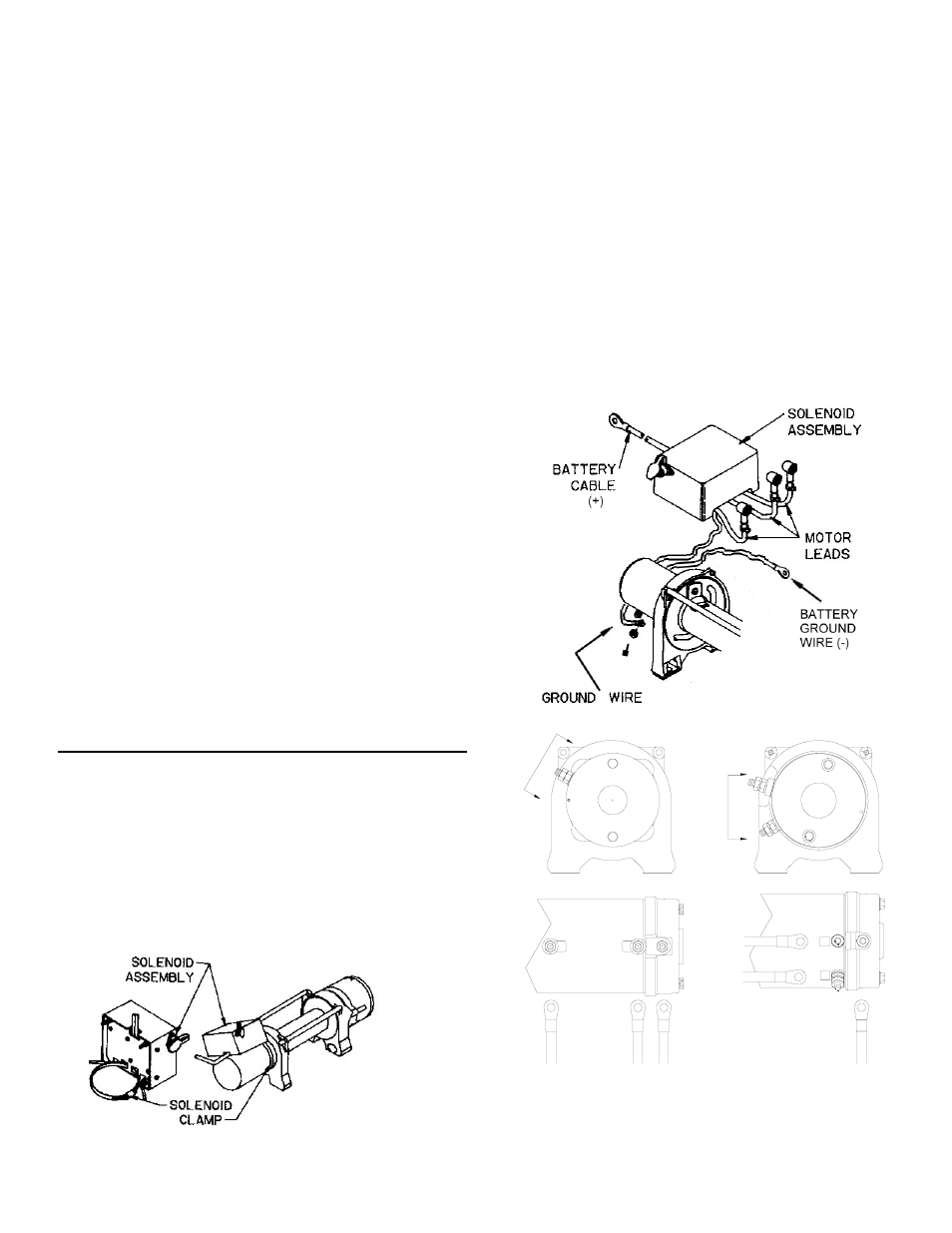

When mounting winch, attach solenoid wires to motor

terminals at end of motor. TIGHTEN NUTS ON MOTOR

TERMINALS SECURELY. Use solenoid clamp to attach

solenoid assembly to winch motor (see FIGURE 1).

Position solenoid at about a 45° angle for clearance of

lower winch guard tube of kit. TIGHTEN CLAMP

SECURELY.

REP 8000 12V & 24V/9000 12V

When mounting winch, connect labeled motor leads

coming from solenoid assembly to appropriately marked

motor terminals. TIGHTEN NUTS ON MOTOR TERMI-

NALS SECURELY (see FIGURE 3). Attach solenoid

ground wire to grounding bolt located at bottom of motor

(See FIGURE 2). Battery ground wire is already installed

to grounding bolt on motor.

Use solenoid clamp, as shown in FIGURE 1, to secure

solenoid assembly to winch motor. If installing in combo

mounting kit, position at about a 45° angle for clearance

of lower winch guard tube in kit. Be sure that clamp is

clear of motor terminals. TIGHTEN CLAMP SECURELY.

FIGURE 1

FIGURE 2

4

View A-A

A

1

2

A

A

A

A

View A-A

A

2

1

F2

F1

F1

F2

FIGURE 3

REP 8000 12v

REP 8000 24v

REP 9000 12v