Operation, Caution – Lincoln Electric IM10122 SAE400 User Manual

Page 14

B-3

OPERATION

B-3

ENGINE TEMPERATURE GAUGE

Displays the coolant temperature in the engine block.

ENGINE OIL PRESSURE GAUGE

Displays the oil pressure to the engine. When the engine

starts running, watch for the oil pressure to build up. If no

pressure shows within 30 seconds, stop the engine and

consult the engine instruction manual.

BATTERY CHARGING AMMETER

Displays the current going from the charging alternator

into the batteries. It is normal for charging current to be

high (above 15 amps) after starting or when the batteries

are ʻlowʼ on charge.

ENGINE HOUR METER

The engine hour meter records the total running time on

the engine in hours. It can be used to keep a record of

maintenance on the engine and or welder.

ENGINE PROTECTION SYSTEM

The engine protection system shuts down the engine

under high coolant temperature or low engine oil pressure

conditions by allowing the fuel solenoid valve to close.

WELDER CONTROLS

POLARITY SWITCH

Turn the Arc Polarity switch to electrode positive or elec-

trode negative as required for each particular application.

CONTROL OF WELDING CURRENT

Purpose of Controls

The continuous “Current Control” is the main current

adjuster. The “Job Selector” is both a fine current adjuster

and the continuous Open Circuit Voltage adjuster. Open

Circuit Voltage (OCV) controls the arc characteristics.

“Job Selector”

The “Job Selector” dial is divided into four colored sec-

tions providing OCV ranges as follows:

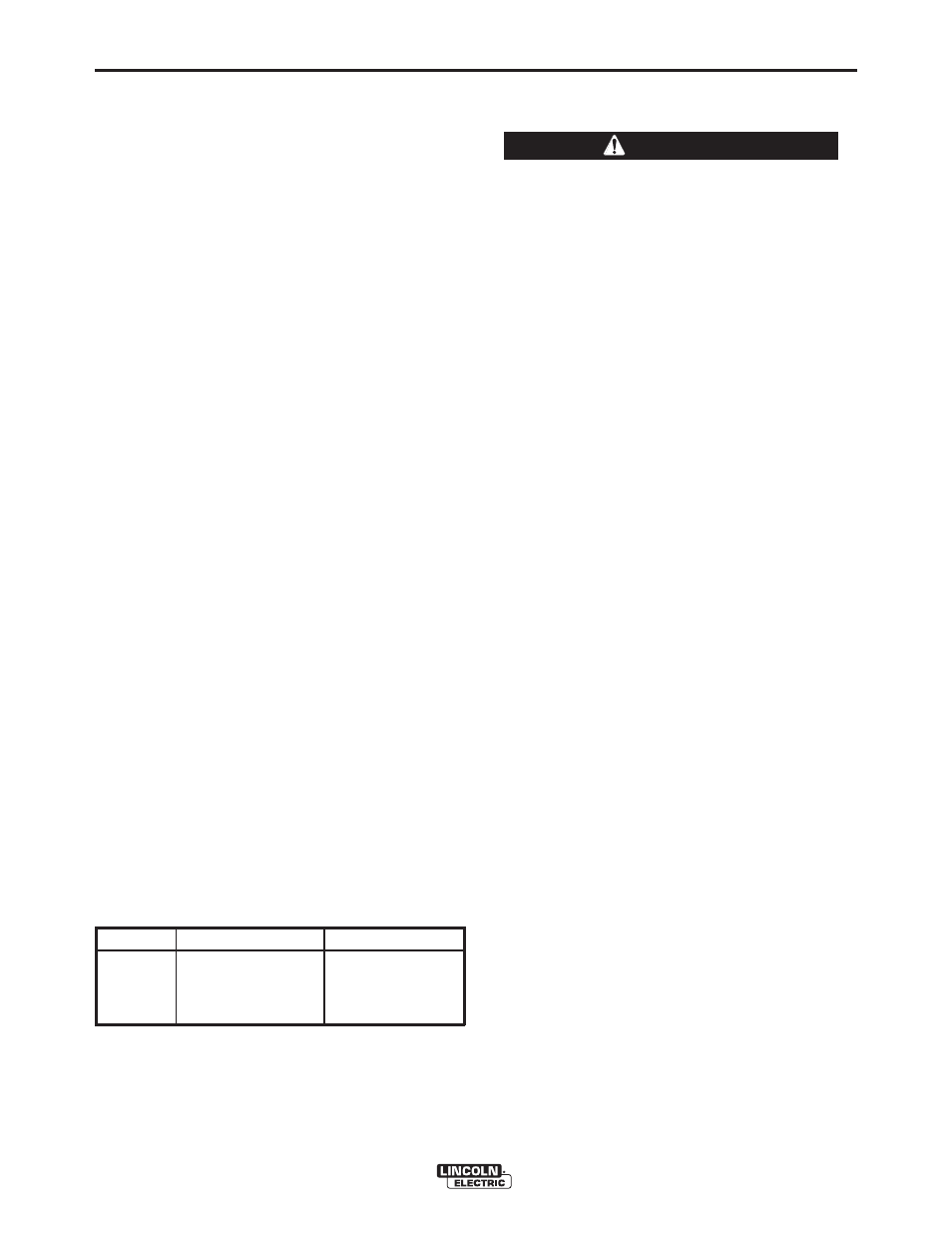

Color

Title

OCV Range

White

Large Electrodes

High OCV

Black

Normal Welding

Medium OCV

Red

Overhead & Vertical

Low OCV

Grey

Special Applications

Extra-Low OCV

The “Job Selector” is usually set in the black range

because it provides a soft “Buttering “ arc desired for most

welding. Some operators prefer to set the “Job Selector”

in the red range for a snappy “Digging” arc when welding

vertical up or overhead.

“CURRENT CONTROL”

Do not adjust the “Current Control” while welding

because this can damage the control.

------------------------------------------------------------------------

The “Current Control” dial is calibrated in amperes on

three separate colored dials corresponding to the

white, black and red ranges of the “Job Selector” dial.

For example: when the “Job Selector” is set on the

black range, the approximate welding current is indi-

cated on the black scale of the “Current Control” dial.

How to Set the Controls

Assume you want a normal soft arc and about 135

amps, using a 5/32” (4.0 mm) electrode:

1. Set the “Job Selector” at the center of the black

range.

2. Set the “Current Control” to read 135 amps on the

black dial.

3. Start to weld.

4. If you want a little more current, turn the “Job

Selector” up (counterclockwise) to increase cur-

rent. If you want a little less current, turn the “Job

Selector” down (clockwise) to decrease current.

5. If dialing the desired current with the “Job

Selector” moves the setting outside the black

range causing undesirable arc characteristics, turn

the “Job Selector” back to the center of the black

range. Then turn the “Current Control” up or down

a little as needed. Readjust the “Job Selector” for

the exact characteristics and current desired.

REMOTE CONTROL

A receptacle and “Local/Remote” control switch is

located on the lower front control panel. A remote con-

trol box with 100 ft. (30.5 m) of cord for adjusting the

OCV at the welding site is available. Putting the switch

in the “REMOTE” position allows fine current control at

the remote control box while placing the switch in the

“LOCAL” position allows fine current control at the “Job

Selector” on the machine. When using the optional

field installed CV adapter (K385-[ ]) the “Local/Remote”

switch is only active in the “VV” mode.

SAE-400

®

CAUTION