Operation, B-2 recommended applications, Design features and advantages – Lincoln Electric IM10027 SAE400 User Manual

Page 14: Duty cycle, Engine controls

B-2

OPERATION

B-2

RECOMMENDED APPLICATIONS

WELDER

The SAE-400® provides excellent constant current

DC welding output for stick (SMAW) welding. The field

installed optional CV Adapter (K385-[ ]) provides up to

500 amps at 35 volts of constant voltage output for

semiautomatic welding.

AUXILIARY POWER

The SAE-400® provides 3 KW of 115/230 VAC output

for auxiliary power and emergency standby power.

DESIGN FEATURES AND ADVANTAGES

FOR STICK WELDING

• Excellent DC constant current output for stick weld-

ing applications.

• Continuous adjustment of both voltage and current

for unsurpassed welds on demanding jobs.

• Remote control capability standard.

FOR AUXILIARY POWER

• 3,000 watts of 115/230VAC, 60 Hz auxiliary power.

• One 20 amp 115VAC duplex receptacle.

• One 15 amp, 230VAC duplex receptacle for up to 13

amps of 230VAC power.

• One 115VAC (European IEC-309) 16 amp receptacle.

• One 230VAC (European IEC-309) 15 amp receptacle.

• Weld and AC auxiliary power at the same time (with-

in the limits shown on the chart below).

OTHER FEATURES

• Perkins 4-cylinder, water cooled diesel engine.

Designed for long life, easy maintenance and excel-

lent fuel economy.

• Engine protection system shuts the engine down for

low engine oil pressure or high coolant temperature.

• Electronic Engine Idler. Engine automatically goes

to low idle in 10 to 14 seconds after welding or use

of auxiliary power stops. Includes high idle switch.

• Gauges for engine oil pressure, coolant temperature

and battery charging ammeter.

• Engine hour meter standard.

• Extended range 22.5 gallon (85.1 L) fuel tank.

DUTY CYCLE

Duty cycle is the percentage of time the load is being

applied in a 10 minute period. For example a 60% duty

cycle, represents 6 minutes of load and 4 minutes of

no load in a 10 minute period.

ENGINE CONTROLS

IGNITION SWITCH

When placed in the “ON” position, this switch ener-

gizes the fuel solenoid. When placed in the “OFF” posi-

tion, the flow of fuel to the injection pump is stopped to

shut down the engine.

“IDLER” SWITCH

The idler switch has two positions, “HIGH” and

“AUTO”.

When in “HIGH” ( ) position, the engine will run

continuously at high idle.

When in “AUTO” ( / ) idle position, the idler

operates as follows:

a. Welding

When the electrode touches the work, the welding

arc is initiated and the engine accelerates to full

speed.

After welding ceases (and no auxiliary power is

being drawn), the engine will return to low idle after

approximately 10 to 14 seconds.

b. Auxiliary Power

With the engine running at low idle and auxiliary

power for lights or tools is drawn (approximately

100-150 watts or greater) from the receptacles, the

engine will accelerate to high speed. If no power is

being drawn from the receptacles ( and not weld-

ing) for 10-14 seconds, the idler reduces the engine

speed to low idle.

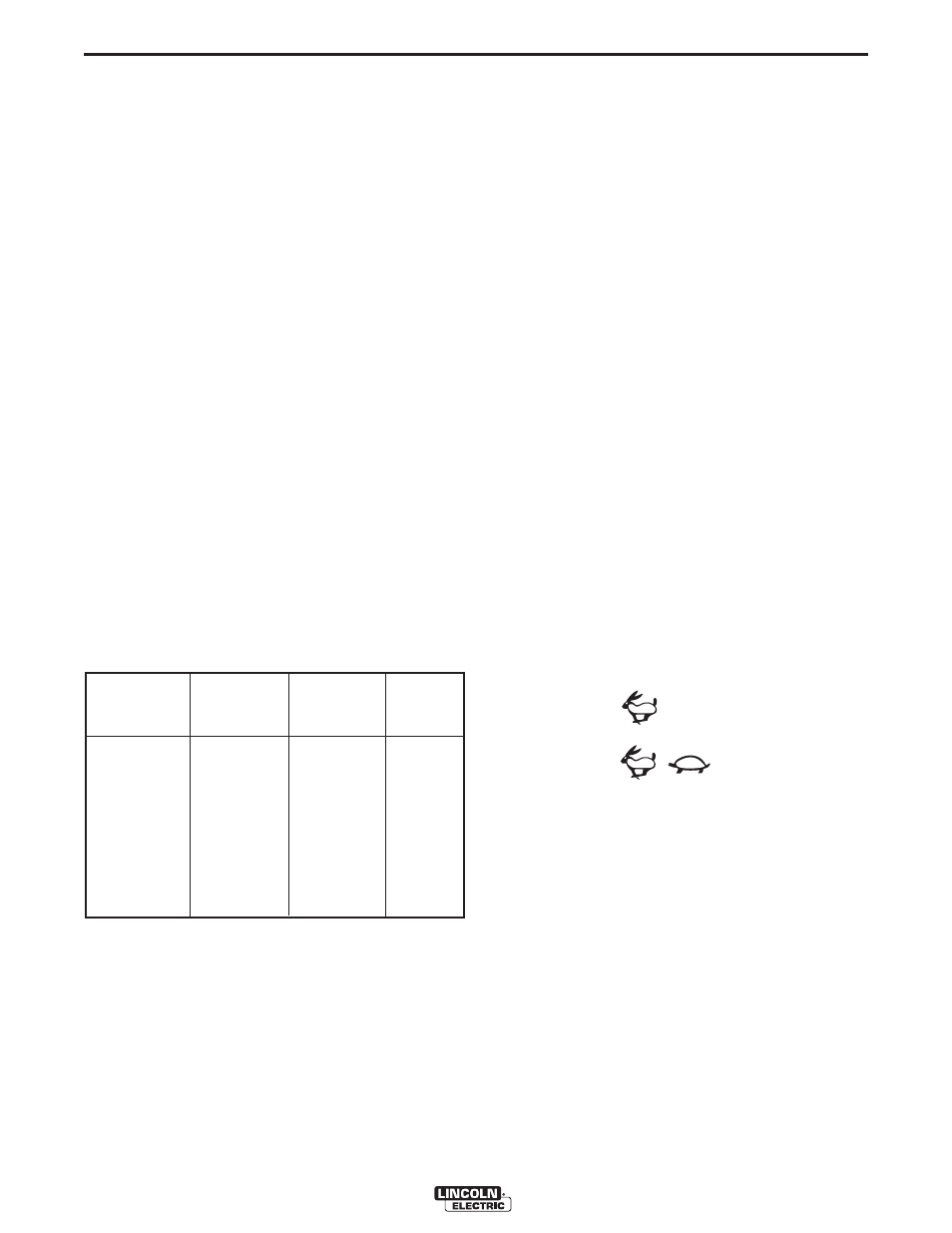

SAE-400®

Welding

Using Only

Using Only

Total

Current, Amps

115V Circuit,

230V Circuit,

Aux.

@ NEMA Arc

Amps

Amps

kVA

Volts

0

26

13

3.0

100

19.5

9.75

2.25

200

13

6.5

1.5

300

6.5

3.25

0.75

400

0

0

0

500

0

0

0