Use instructions – Vestil S-FORK-4-AT User Manual

Page 4

S-Fok-4-AT manual

07/19/11

Use Instructions:

Only trained, designated persons should use the fork attachment. “Designated person” means someone selected by

his employer to use the device. Trainees under the direct supervision of a designated person also may use the S-Fork.

Maintenance personnel also may use the S-Fork when necessary to perform employment duties.

Step 1: Inspect the S-Fork.

The user should perform an “Inspection[s] Before & During EVERY Lift” on p. 5, prior to connecting the attachment to the

tine of a fork truck. Proceed to the next step ONLY IF the attachment passes the inspection.

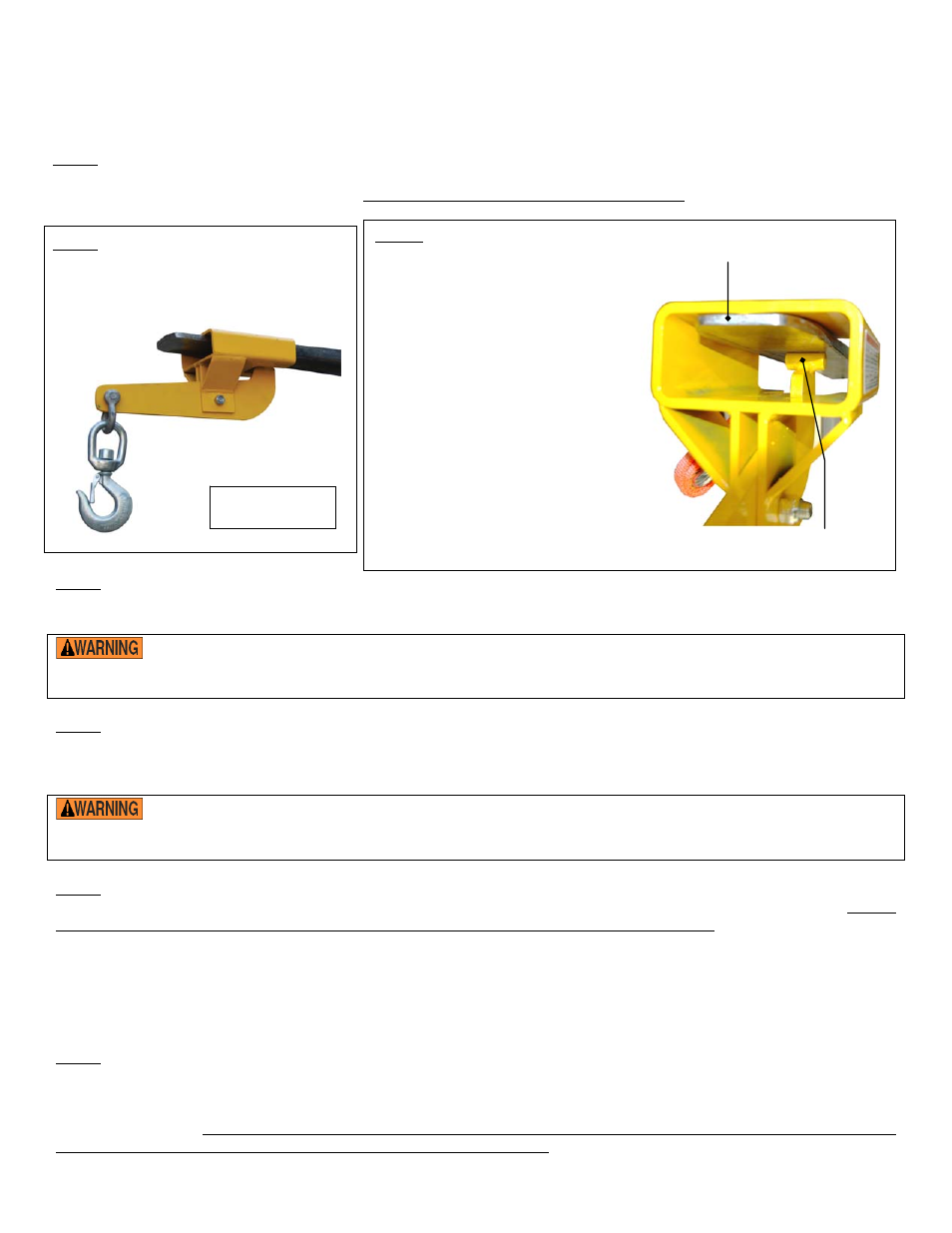

Step 3: Secure the S-Fork to a tine

with the safety strap.

Attach the safety strap to the

carriage of the fork truck WITHOUT

slack and connect the snap hook (at

the end of the strap) to the strap.

Remove any slack in the strap by

pulling it tight. Pull the strap from the

end that connects to the cold shut

(see FIG. 1 on p. 3). Verify that the

S-Fork cannot slide off of the tine by

tilting the fork truck mast forward.

The S-Fork should be positioned on

the tine as shown in Photo 1.

NOTE: The S-Fork can still slide

toward the lift carriage UNTIL the

weight of the load presses the tine

lock against the underside of the

tine.

Tine lock

Tine of forklift

Step 2: Connect S-Fork to a fork truck tine.

Slide the device over the end of a tine;

then position the S-Fork at the desired

point along the length of the fork tine

Photo 1 – Position

S-Fork on Tine

Step 4: Connect the load to the load hook.

Position the S-Fork above the load and adjust the vertical position as necessary. Follow the lifting/hoisting procedures

applied at your worksite to properly attach the load to the S-Fork hook.

Account for the possibility of load swing by making sure that the load is oriented to prevent tipping, rolling, or

otherwise reorienting when it is lifted from the ground. The swinging motion could result in serious injuries to the fork lift operator

or other persons in the area.

Step 5: Test the contact between the hook (of the S-Fork) and the load.

Tell every person in the area to clear the usage area including the travel path and then raise the forks sufficiently to

elevate the load just a few inches. Verify that the connection is sound by leaving the load suspended for a moment.

Proceed to the next step ONLY IF the connection is stable.

DO NOT attempt to lift and/or transport a load if a secure connection cannot be achieved. Return the load to

the ground and adjust the connection; then repeat step 5. If the connection still is not stable, return the load to the ground

and select a different lifting device to lift and move the load.

Step 6: Transport the load to the intended location.

Slowly drive the forklift to the desired location and adjust the driving speed to minimize the degree of drum swing. Always

follow the procedures applied at your worksite for safely hoisting material and operating a forklift.

NOTE 1: The load will swing more significantly the greater the driving speed. Drive slowly to minimize movement

during transport.

NOTE 2: The load will tend to swing opposite the direction of a turn and will swing out in front of the forklift during

braking. Apply the brakes gradually and reduce speed during all turns to reduce the effect on the

suspended load.

Step 7: Return the load to the ground and disconnect the S-Fork from and load.

Only set the load on a flat, level surface to prevent unintended or uncontrolled movement as the load settles. Before

lowering the load, make sure that it is not swinging or rotating. Slowly lower the forks until the load contacts the ground.

Continue to lower the load to create slack between the shackle and load hook (of the S-Fork), and then disconnect the

load from the hook. DO NOT disconnect the load from the hook until the load is immobilized (if necessary) to prevent it

from rolling, falling over, or otherwise moving in an uncontrolled manner.

Page 4 of 7

Copyright 2011 Vestil Manufacturing Corp.