Diagram 6: rotate crane onto its feet – Vestil AHA User Manual

Page 20

Copyright 2011 Vestil Manufacturing Corp.

Page 20 of 25

Step 5: Tighten the beam clamp fasteners. Make sure that the I-beam is centered on the beam brackets and that the beam

clamps significantly overlap the beam flange on both sides.

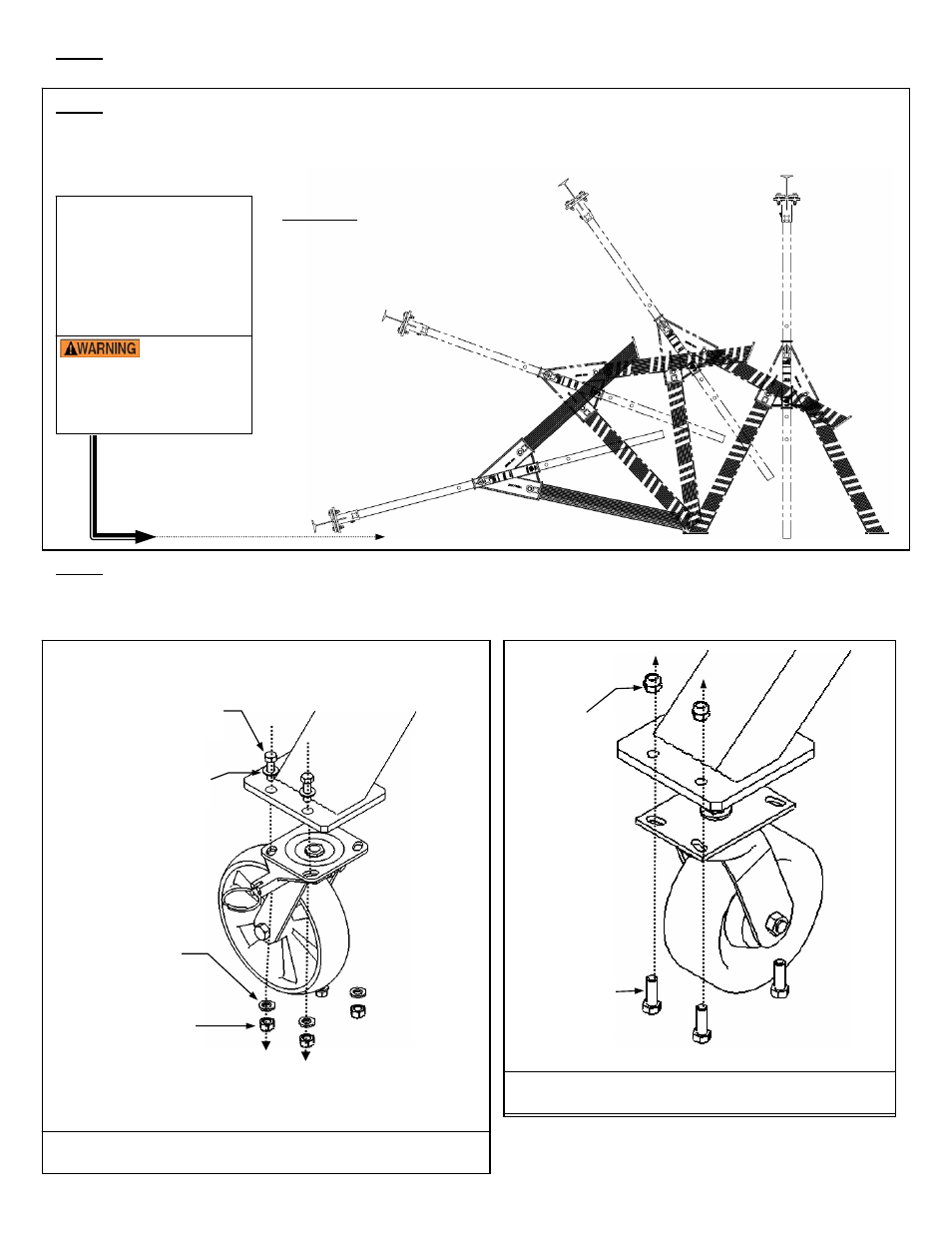

Step 6: Stand the crane on its feet.

Rotate the crane onto its feet in a controlled manner. [For instance, attach a hoist chain to the I-beam and then slowly

raise the beam until the crane rotates to stand on its feet. Alternatively, raise the crane with a fork truck: Position the forks

under the I-beam and slowly raise the beam until the crane rotates onto its feet in a controlled manner.]

Step 7: Connect the casters to the legs (Diagrams 5A & 5B show standard casters).

Attach each caster to the caster mount bracket of each leg using the hardware shown in Diagrams 5A & 5B. Raise the

crane 8 to 10 inches off of the ground with a fork lift or hoist. Position a caster underneath each foot as shown in the

diagram below and fasten it to the caster mount bracket.

3

Approach the crane with a

fork truck from this side, and

slide the forks under the I-

beam.

Slowly raise the beam and

slowly drive forward until the

crane stands on its feet.

DO NOT raise

the beam unless all other

persons have moved to a

location away from and

behind the fork truck.

3

3

/

8

in. -16 x 1¼ in. HHCS

#2 zinc-plated bolt

3

/

8

in. zinc-plated

lock washer

3

/

8

in. zinc-plated

hex

nut

Diagram 7B: Caster installation for 6,000 lb. capacity

models (AHA-6-#-#)

Diagram 7A: Caster installation for 2,000 pound and 4,000

pound capacity models (AHA-2-#-# and AHA-4-#-#)

½ in. -13 x 1½ in.

HHCS #2 zinc-

plated bolt

½ in. – 13 nylon

insert lock nut

3

/

8

in. SAE zinc-plated

flat washer

Diagram 6: Rotate crane onto its feet

Slide a lock washer followed by a flat washer onto a 1¼ in. bolt, and

feed the bolt up through the bolt holes in the caster and caster mount

bracket. Put a lock washer onto the bolt and fasten a nut to the end of

the bolt.