System Sensor WFD European Models User Manual

Page 2

D770-53-00

2 I56-2617-004R

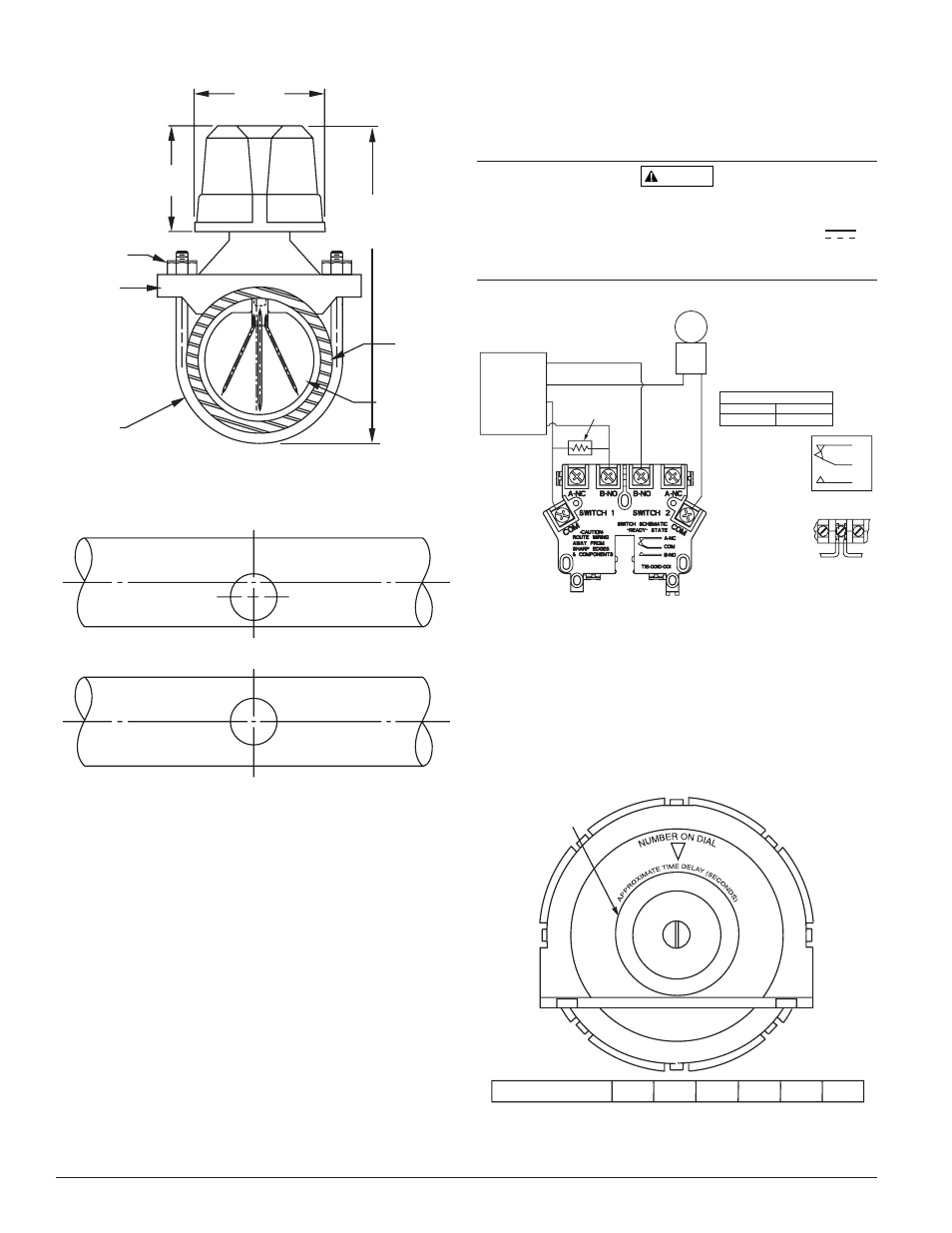

FIGURE 1. MOUNTING DIMENSIONS:

7.6 CM

(3˝)

9.5 CM

(3

3

/

4

˝)

PIPE DIAMETER

PLUS 13.3 CM

(5

1

/

4

˝)

PIPE

VANE

PIPE

U-BOLT

NUT

PIPE

SADDLE

U-BOLT

OVERALL WIDTH = PIPE DIAMETER + 7.6 CM (3˝)

W0105-00

FIGURE 2. LOCATION OF MOUNTING HOLE:

WRONG

RIGHT

REMOVE BURRS FROM EDGE OF HOLE. CLEAN OUT SCALE

AND FOREIGN MATTER FROM INSIDE WALL OF PIPE.

W0106-00

PREOPERATION TESTING

1. Fill the sprinkler system and check for leaks around the WFDE. If it

leaks, first check for proper torque on U-bolt nuts. If leak persists, drain

the system and remove the detector (see removal instructions under

Maintenance). Check for dirt or foreign objects under the gasket. Check

that pipe surface is not dented. Reinstall the detector and check again for

leaks. Do not proceed until all leaks have been stopped.

2. Connect an ohmmeter or continuity tester across (COM and B-NO) termi-

nal switch contacts (see Figure 3). The ohmmeter should show an open

circuit, no continuity.

3. Deflect the actuator lever and hold it until the pneumatic delay shaft

releases the switch buttons. The ohmmeter or continuity tester should

show a short circuit after the delay has elapsed. If there is no delay,

check the setting of the delay adjustment dial.

FIELD WIRING

1. All models have two SPDT switches. Switch contacts (COM and B-NO) are

closed when water is flowing and open when water is not flowing. Con-

nect the switches as shown in Figure 3 depending on the application.

2. When connected to a listed sprinkler/fire alarm control panel, the initiat-

ing circuit must be non-silenceable.

3. A ground screw is provided with all WFDE units. When grounding is re-

quired, clamp wire with screw in hole located between conduit entrance

holes, see Figure 6.

4. Use proper waterproof conduit fittings where required.

5. A 22.2 mm conduit hole is provided for electrical connection. An additional

22.2 mm diameter knockout is provided for multiple line connections.

WARNING

High Voltage. Electrocution Hazard. Do not handle live AC wiring or work on a de-

vice to which AC power is applied. Doing so may result in severe injury or death.

When utilizing switches at voltages greater than 74VDC

or

49VAC

~

means to provide all–pole disconnection must be incorporated in

the field wiring, such as a circuit breaker.

FIGURE 3. FIELD WIRING:

+

+

–

–

SSM24-X

SSV120-X

NOTE: COMMON AND B-NO

CONNECTIONS WILL CLOSE

WHEN VANE IS DEFLECTED, I.E.,

WHEN WATER IS FLOWING. DUAL

SWITCHES PERMIT

APPLICATIONS TO BE COMBINED

ON A SINGLE DETECTOR.

BREAK WIRE AS

SHOWN FOR

SUPERVISION OF

CONNECTION. DO

NOT ALLOW

STRIPPED WIRE

LEADS TO EXTEND

BEYOND SWITCH

HOUSING. DO NOT

LOOP WIRES.

POWER

24VDC OR

120VAC

INITIATING

LOOP

UL-LISTED

COMPATIBLE

CONTROL PANEL

CONTACT RATINGS

125/250 VAC

24 VDC

10 AMPS

2.5 AMPS

SCHEMATIC OF

INDIVIDUAL

SWITCH IN

“NO WATERFLOW”

CONDITION

SUGGESTED EOL

RESISTOR

B-NO

COM

A-NC

W0356-01

MECHANICAL DELAY ADJUSTMENT

The pneumatic delay is preset at dial setting 25 at the factory. To adjust the

delay, turn the adjustment dial on the delay mechanism. Turn clockwise to

increase the delay, counterclockwise to decrease the delay. Delay can be ad-

justed over a range from 0 to 30 seconds maximum, see Figure 4.

NOTE: Set the delay to the minimum required to prevent false alarms due to

flow surges.

After extended service, parts of the detector may become worn reducing the

delay time and causing false alarms. If this happens, increase the delay.

FIGURE 4. DELAY ADJUSTMENT DIAL:

20

0

5

10

15

25

DIAL SETTING

0

5

10

15

20

25

DIAL SETTING EQUALS DELAY IN SECONDS REFERENCE ONLY.

DELAY

ADJUSTMENT

DIAL

W0102-04