System Sensor PIBV2 User Manual

Page 2

N770-03-00

3

I56-0394-010R

SECTION 4

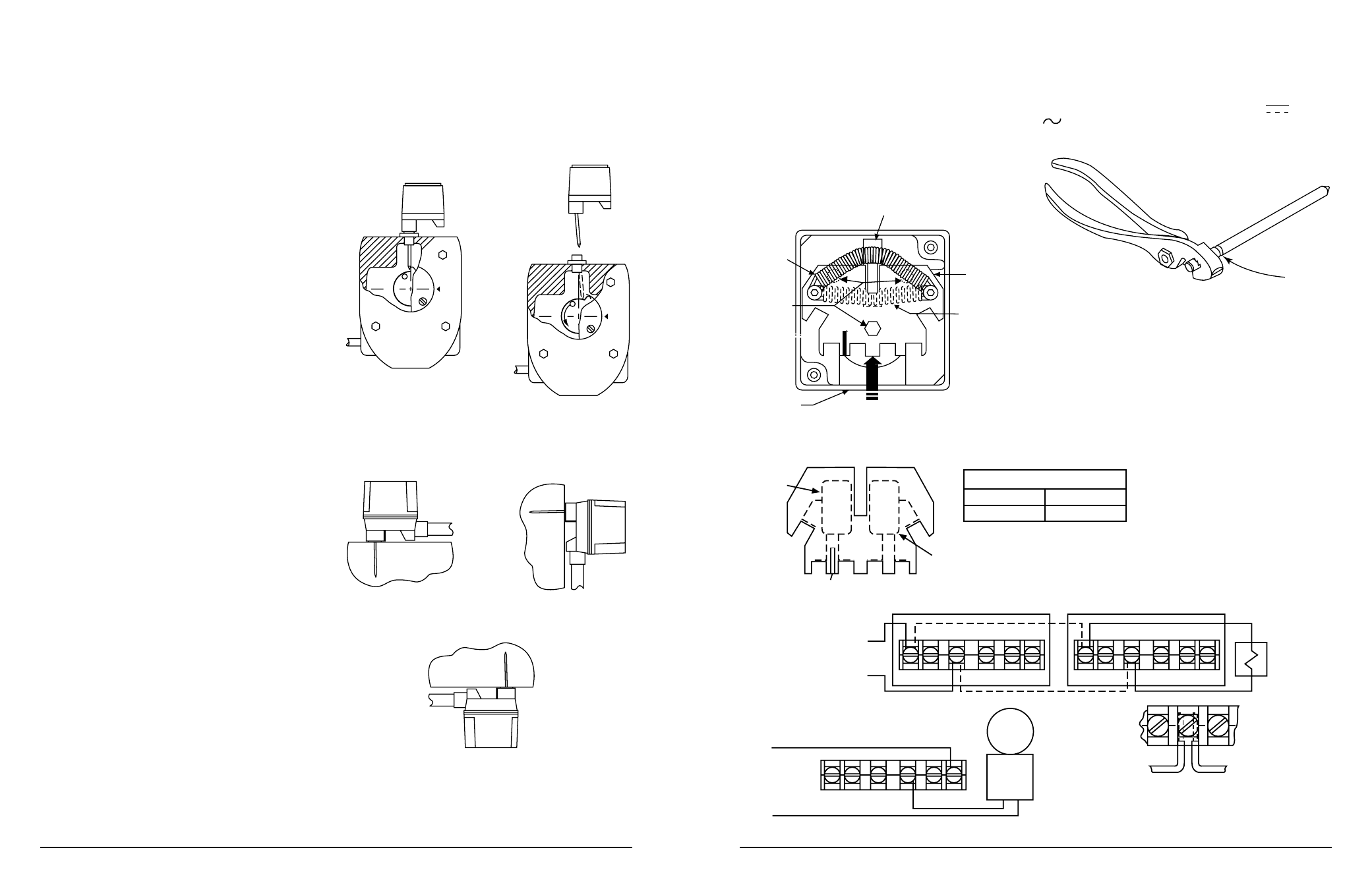

REVERSINg ThE ACTION OF PIBV2

1. Loosen the three

3

/

16

˝ hex (socket head) screws on the top of the black

switch enclosure so that the switch enclosure is loose and free to move

(see Figure 5).

2. Slide the switch enclosure away from the conduit entry toward the actu-

ating pivot arm as far as possible and tighten the 3 screws to secure the

enclosure. (Ensure that switch enclosure remains oriented away from the

conduit entry as screws are tightened.)

3. Grasp the spring at the center and lift it over the actuating cam so that it

seats on the opposite side of the actuator (see Figure 5).

NOTE: Lever actuator may need to be adjusted to allow spring to be moved.

FIgURE 5:

CONDUIT

ENTRY

SOCKET

HEAD

SCREW

SPRING

IN FINAL

POSITION

ACTUATING LEVER

SWITCH

ENCLOSURE

SPRING

IN INITIAL

POSITION

SLIDE IN

THIS DIRECTION

W0225-00

WARNING: High Voltage. Electrocution Hazard. Do not handle live AC wiring

or work on a device to which AC power is applied. Doing so may result in

severe injury or death.

When utilizing switches at voltages greater than 74 VDC

or 49 VAC

, means to provide all-pole disocnnection must be incorporated in the

field wiring, such as a circuit breaker.

FIgURE 7: ACTUATINg ARM BREAkAwAy FEATURE:

BREAK

HERE

W0321-00

N770-03-00

2

I56-0394-010R

4. (a) In a falling flag installation (flag lowers as valve is closed), measure

the distance from the bottom of the head to the upper surface of the

target that will contact the actuating lever of the PIBV2. Add

3

⁄

32

˝ to this

measurement and mark the outside of the housing at that location. Drill

with a

23

⁄

32

˝ drill bit and tap a

1

⁄

2

˝ NPT thread.

(b) In a rising flag installation (flag rises as valve is closed), measure the

distance from the bottom of the head to the lower surface of the target

that will contact the actuating lever. Subtract

3

⁄

32

˝ to this measurement

and mark the outside of the housing at that location. Drill with a

23

⁄

32

˝

drill bit and tap a

1

⁄

2

˝ NPT thread.

5. Replace the head and target assembly.

6. Loosen the set screw that holds the nipple on the PIBV2 and remove

the nipple.

7. Screw the locknut onto the threaded nipple which is supplied with the PIBV2.

8. Screw the nipple hand tight into the

1

⁄

2

˝ hole in the valve and tighten the

locknut against the housing to secure the nipple in position.

9. Insert a probe into the hole through the nipple to measure the distance

from the open end of the nipple to the desired position on the target as-

sembly. Subtract

5

⁄

8

˝ from the distance and set the length of the actuating

lever of the PIBV2 from the end of the enclosure to this distance. Tighten

the screw which holds the actuating lever.

NOTE: Place cover over PIBV2 to ensure that actuating lever does not

interfere with cover. If actuating lever interferes with cover, remove

lever and break off additional length at breakaway point. Repeat step

8 to re-install actuator lever. Refer to Figure 7.

10. Close the valve 3 to 4 revolutions.

11. Install the PIBV2 onto the nipple and orient the conduit entry down (See

Figure 4). Apply pressure to the PIBV2 and lock the set screws to secure

the nipple to the PIBV2.

12. Slowly open the valve to its fully open position. The switch should trip

as the valve opens, but not force the actuating lever against the nipple

when fully open. To check for this condition, open the valve fully and

depress the top of the actuating cam to stretch the actuating spring fur-

ther. There should be some additional movement available. If no move-

ment is available, damage may occur to the PIBV2 actuator lever. It will

be necessary to adjust the flag location by removing the head and turn-

ing the handle while the valve stem is disengaged (refer to the valve

manufacturer.)

13. After checking the fully open position to ensure adequate clearance,

close the valve slowly until the PIBV2 contacts trip. The switches must

trip within

1

⁄

5

of the full travel distance of the valve.

14. If the PIBV2 does not change states within

1

⁄

5

of the length of travel, it

may be necessary to adjust the flag up or down by removing the head

and turning the handle (refer to the valve manufacturer.)

SECTION 2

INSTALLATION INSTRUCTIONS FOR BUTTERFLy VALVES (SEE FIgURE 3)

1. Remove the

1

⁄

2

˝ NPT plug from the valve housing.

2. Loosen the set screw that holds the nipple on the PIBV2 and remove

the nipple.

3. Screw the locknut onto the threaded nipple which is supplied with the

PIBV2.

4. Screw the nipple into the

1

⁄

2

˝ NPT hole and hand tighten. Tighten the

locknut firmly to the housing to secure the nipple.

5. Open the valve fully and close the valve approximately 3 revolutions,

noting which direction the target moves.

6. Retract the actuating arm and install PIBV2 onto the nipple, orienting the

PIBV2 to trip the switch as the valve closes. If the conduit entry is on the

wrong side, it will be necessary to reverse the action of the switch (see

Section 4). Apply pressure to PIBV2 and tighten set screw to secure the

assembly.

7. Slide the actuating arm into the valve until it bottoms on the flag, but do

not tighten the screw which holds the actuating lever.

NOTE: Place cover over PIBV2 to ensure that actuating lever does not

interfere with cover. If actuating lever interferes with cover, remove lever

and break off additional length at breakaway point. Refer to Figure 7.

8. Open the valve to the full open position and tighten screw to hold actuat-

ing arm in position. (Actuating arm length will adjust slightly as valve is

opened.) Check to ensure that in the full open position the actuating arm

is not resting on the nipple. Do this by depressing the actuating cam to

further stretch the spring, ensuring that more travel is available when the

valve is open. If there is no travel, damage may occur to PIBV2 actuating

arm. Some slight alteration of the valve stop setting may be necessary to

ensure that no damage occurs.

9. Carefully close valve and note the number of handle revolutions until the

switch trips. The switch must trip within 1⁄5 of the total travel range of

the valve.

FIgURE 3:

TO

O

P

E

N

CLOSE

CLOSE

W0214-00

SECTION 3

gENERAL INSTALLATION INSTRUCTIONS

1. Installation Positions

FIgURE 4:

ACTUATOR VERTICAL (DOWN)

ACTUATOR HORIZONTAL

ACTUATOR VERTICAL (POINTING UP)

EXAMPLES OF ACCEPTABLE MOUNTING POSITIONS:

EXAMPLE OF MOUNTING POSITIONS

NOT ACCEPTABLE:

W0381-00

2. Ground Screw — A ground screw is provided with all supervisory switch

models. When grounding is required, clamp wire with the screw in hole

located near conduit entrance.

3. Wiring — See Figure 6, Page 4.

FIgURE 6:

TOP VIEW

SWITCH 1

CO

M

CO

M

A

B

B

A

SWITCH 2

CONTACT RATINGS

125/250 VAC

24 VDC

10 AMPS

2.5 AMPS

SUP. SWITCH

B

B

COM

COM

SUP. SWITCH

B

B

COM

COM

TYPICAL FACP CONNECTION

TO NONSILENCEABLE

INITIATING ZONE

OF LISTED FACP

END-OF-LINE

RESISTOR

B

COM

TO POWER

SOURCE

COMPATIBLE

WITH BELL

LOCAL

BELL

TYPICAL LOCAL BELL CONNECTION

BREAK WIRE AS SHOWN FOR SUPERVISION

OF CONNECTION. DO NOT ALLOW STRIPPED

WIRE LEADS TO EXTEND BEYOND SWITCH

HOUSING. DO NOT LOOP WIRES.

STRIP GAUGE

NOTE: COMMON AND B CONNECTIONS

WILL CLOSE WHEN VALVE MOVES

1

/

5

OF

ITS TOTAL TRAVEL DISTANCE.

W0223-00