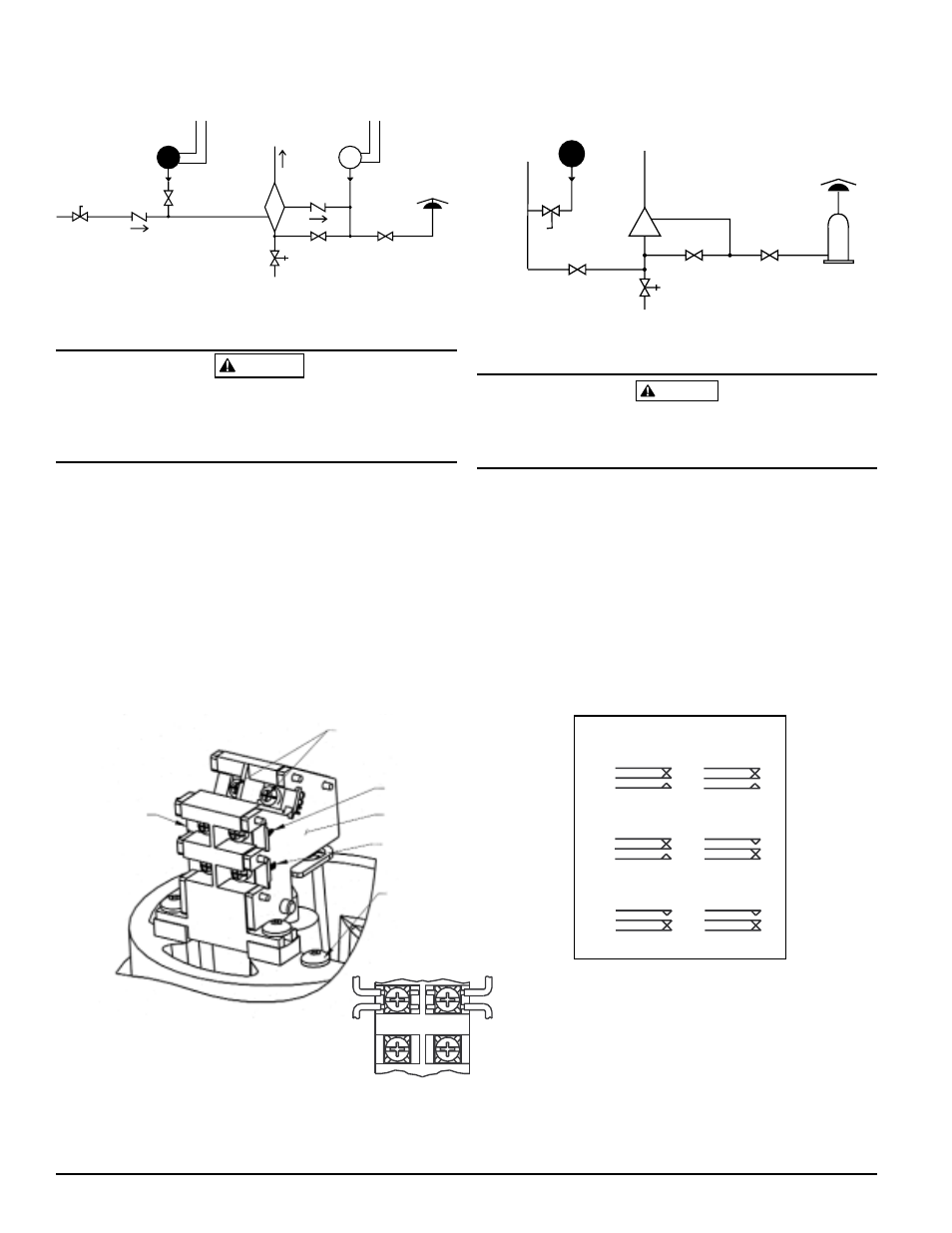

Figure 3. typical piping diagram for eps120exp, Figure 4. switch location, Figure 2. typical piping diagram for eps40exp – System Sensor EPS40EXP and EPS120EXP User Manual

Page 2: Warning

BREAK WIRE AS SHOWN FOR

SUPERVISION OF CONNECTION.

DO NOT ALLOW STRIPPED WIRE

LEADS TO EXTEND BEYOND

SWITCH HOUSING. DO NOT

LOOP WIRES.

A78-2346-02

D770-26-00

2

I56-1428-001R

Installation

1. Back out cover tamper set screw and remove cover (Fig. 1).

2. Mounting the Switch

The device is designed to be mounted in the upright posi-

tion; side mounting is also acceptable. Locate it where

vibration, shock, and mechanical loading are minimal.

Refer to piping diagram above (Figures 2 and 3).

a. Mount the device directly to the line via the 1/2″ NPT

pressure connection. The use of teflon pipe sealant

tape is recommended. Be sure the fitting is tight

enough to prevent leaks.

A78-2397-00

Figure 3. Typical piping diagram for EPS120EXP

DRY

PIPE

VALVE

OS & Y

VALVE

WATER

BY-PASS

TEST

VALVE

LOCAL ALARM

SHUT OFF

VALVE

WATER

MOTOR

GONG

CHECK

VALVE

EPS40EXP

CHECK

VALVE

AIR LINE

SHUT-OFF

VALVE

INSTALL

BLEEDER

VALVE FOR

TESTING

EPS10EXP

DRY SYSTEM

WIRE TO SUPERVISORY

CIRCUIT OF FIRE ALARM

CONTROL PANEL

WIRE TO ALARM

INDICATING CIRCUIT

OF FIRE ALARM

CONTROL PANEL

TO

SPRINKLER

SYSTEM

Table 1. Electrical connections (referenced at

factory settings):

b. Apply tightening torque to the brass hex portion of

the device.

High voltage. Electrocution hazard. Do not handle live AC

wiring or work on a device to which AC power is applied.

Doing so may result in severe injury or death.

3. Wire the device in accordance with the National

Electrical Code. Two 1/2″ NPT conduit entry holes have

been provided in the mounting base to accept explosion

proof conduit fittings. If necessary, remove conduit entry

plug with 3/8” square wrench.

4. Connect wiring to terminals (see Figure 4 and Table 1).

CAUTION

WET

SYSTEM

ALARM

CHECK

VALVE

OS & Y

VALVE

OS & Y

VALVE

WATER

BY-PASS

VALVE

AIR

PRESSURE

SUPPLY

BLEEDER

TEST

VALVE

EPS120EXP

LOCAL ALARM

SHUT OFF

VALVE

RETARD

WATER

MOTOR

GONG

A78-2398-02

COMMON

TERMINAL

SWITCH #2

(LOW SWITCH)

TERMINAL

“B”

GROUND

SCREW

Figure 4. Switch location:

WARNING

To prevent ignition of hazardous atmospheres, disconnect

circuits before removing cover. Keep cover closed while cir-

cuits are live. Conduit runs must have sealing fittings con-

nected within 18” of the enclosure.

SWITCH #1

(HIGH SWITCH)

Figure 2. Typical piping diagram for EPS40EXP

SW2

SW1

SWITCHES AT NORMAL SYSTEM PRESSURE

SWITCHES AT LOW TRIP POINT

SW1

SW2

MODELS EPS40EXP, EPS120EXP

SWITCHES AT HIGH TRIP POINT

SW1

SW2

B

COM

A

B

COM

A

B

COM

A

A

COM

B

A

COM

B

A

COM

B