System Sensor DH100 User Manual

Page 3

[5.3] Secure The Detector Housing To The Duct

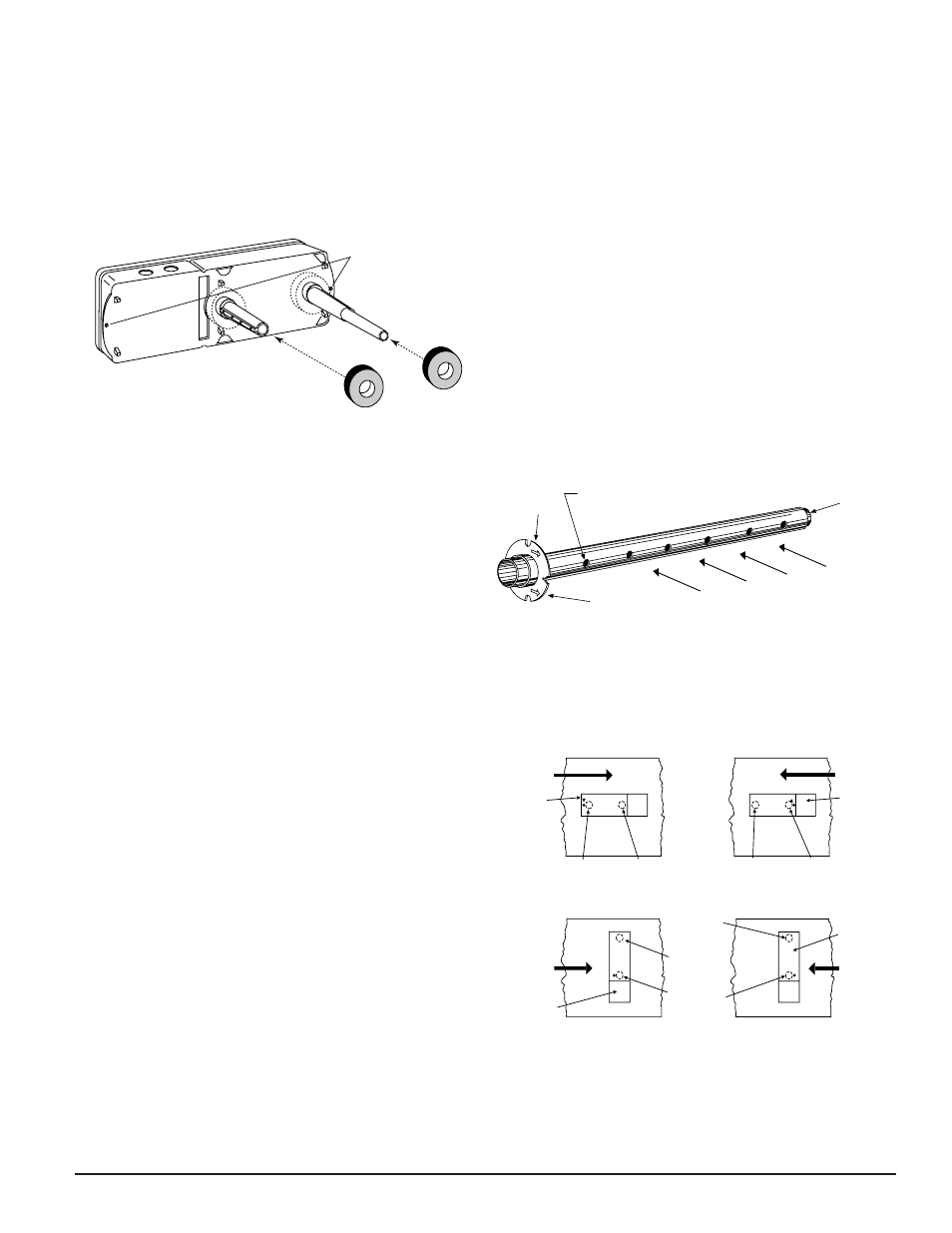

Slide the foam gaskets over the tube bushings as shown in

Figure 3. Use the two 11/4" long sheet metal screws to

screw the detector housing to the duct.

CAUTION: Do not overtighten the screws.

Figure 3. Installation of foam gaskets over sampling

tube bushings:

A78-2045-00

[5.4] Sampling Tube Installation of Ducts Greater

Than 1

1

⁄

2

Feet Wide

The sampling tube is identified by a series of air inlet holes

on the tube. One plastic tube is included for ducts up to 18

″

in width. All other lengths must be purchased separately.

Order the correct length, as specified in Table 1, for width

of the duct where it will be installed. The exhaust tube is

molded onto the base of the duct housing, and the

A2440-00 Exhaust Tube Extension is available as an acces-

sory in those cases where the molded exhaust port does not

extend at least 2 inches into the duct.

The inlet tube is always installed with the air inlet holes

facing into the air flow. To assist proper installation, the

tube’s mounting flange is marked with arrows. Make sure

the inlet tube is mounted so that the arrows point into the

air flow (see Figure 4). Figure 5 shows the various combi-

nations of tube mounting configurations with respect to air

flow. Mounting the detector housing in a vertical orienta-

tion is acceptable, provided that the air flows directly into

the sampling tube holes as indicated in Figure 4.

Table 1. Inlet tubes required for different duct

widths:

Outside Duct Width

Inlet Tube Required

1 to 2 ft.

ST-1.5

2 to 4 ft.

ST-3

4 to 8 ft.

ST-5

8 to 12 ft.

ST-10

[5.4.1] Installation For Ducts Greater Than 1

1

⁄

2

Feet

But Less Than 8 Feet Wide

1. If the tube is longer than the width of the air duct, drill a

3

⁄

4

-inch hole in the duct opposite the hole already cut for

the inlet tube. Make sure the hole is 1

″ to 2″ below the

SCREW HOLES FOR

ATTACHING HOUSING

TO DUCT WORK.

inlet hole on the opposite side of the duct to allow for

moisture drainage. If the tube is shorter than the width of

the air duct, install the end plug into the inlet tube as

shown in Figure 4. Sampling tubes over 3 ft. long must be

supported at the end opposite the duct detector.

2. Slide the tube into the housing bushing that meets the

air flow first. Position the tube so that the arrows point

into the air flow.

3. Secure the tube flange to the housing bushing with two

#6 self-tapping screws.

4. For tubes longer than the width of the air duct, the tube

should extend out of the opposite side of the duct. If

there are more than 2 holes in the section of the tube

extending out of the duct, select a different length using

Table 1. Otherwise, trim the end of the tube protruding

through the duct so that 1

″ to 2″ of the tube extend out-

side the duct. Plug this end with the end plug and tape

closed any holes in the protruding section of the tube. Be

sure to seal the duct when the tube protrudes.

Figure 4. Air duct detector inlet sampling

A78-2047-00

Figure 5. Tube mounting configurations with varying

air flow direction:

AIR FLOW

DIRECTION

DETECTOR

HOUSING

DOTS INDICATE POSITION OF

SAMPLING TUBE HOLES

AIR FLOW

DIRECTION

DETECTOR

HOUSING

INLET

TUBE

EXHAUST

TUBE

AIR FLOW

DIRECTION

EXHAUST

TUBE

INLET

TUBE

INLET

TUBE

EXHAUST

TUBE

DETECTOR

HOUSING

AIR FLOW

DIRECTION

EXHAUST

TUBE

INLET

TUBE

DETECTOR

HOUSING

A.

B.

C.

D.

HORIZONTAL MOUNTING OF HOUSING

VERTICAL MOUNTING OF HOUSING

INLET

TUBE

END

PLUG

AIR HOLES

ARROWS

MUST FACE

INTO AIR FLOW

AIR FLOW DIRECTION

FLANGE

D100-67-00

3

I56-1148-08R

A78-1812-08

NOTE: Only metal sampling tubes may be used on ori-

entations C and D.