Superwinch S4000 - 1,814 kgs/12V User Manual

Page 6

Do not sub-

stitute any

strength grade weaker than

grade 5.

When attaching wires to the motor

terminals and solenoid (relay), hold

the inner nut when tightening the

outer nut. Do not allow the motor

terminals to rotate for it may cause

internal wire breakage or part mis-

alignment. Be especially careful in

preventing the solenoid (relay)

terminals from rotating. Any

rotation can damage the solenoid

(see Figure 10).

Step (3)

Disconnect the vehicle battery

leads.

Automobile

batteries

contain gasses which are flammable

and explosive. Wear eye protection

during installation and remove all

metal jewelry. Do not lean over

battery while making connections.

Step (4)

Route the two (2) wires through

the vehicle grille to the battery. To

ensure against insulation abrasion

and/or cutting, apply several layers

of electrical tape where wiring may

come in contact with sharp metal

parts of the vehicle. Attach the cir-

cuit breaker assembly to the end of

the red wire. Wrap the circuit

breaker assembly with electrical tape

to prevent accidental short circuits.

Attach other end of circuit breaker

assembly to battery positive terminal.

DANGER

!

WARNING

!

I N S TA L L AT I O N

C O N T.

11

Be Prepared

Figure 11

Figure 10

Superwinch mounting (fitting) kits

are available for most popular vehi-

cles. If you can‘t locate a kit locally

contact Superwinch at the address

listed on the front of this manual

for the name of a Superwinch dealer

near you.

Detailed Mounting instructions are

provided with each mounting kit.

Read and follow directions carefully

to ensure proper winch alignment

and trouble free operation.

This winch

MUST be mount-

ed with the wire rope in the under-

wind direction. Improper mounting

could damage your winch and void

your warranty.

MINIMUM ELECTRICAL

REQUIREMENTS

For 12 volt winches, a 60 ampere

alternator and battery with 440

cold-cranking amperes capacity are

the minimum recommended power

sources. If the winch is in heavy use,

an auxiliary battery and heavy duty

alternator are recommended.

Step (1)

Install mounting kit or structural

support for winch.

Step (2)

When mounting the winch, pull the

freespool clutch lever into the freespool

position. Unwind 25-30 feet of rope

from the drum. This will provide the

access needed to install the mounting

bolts into the base plate mounting holes.

WARNING

!

I N S TA L L AT I O N

M O U N T I N G

Y O U R W I N C H

NOTES

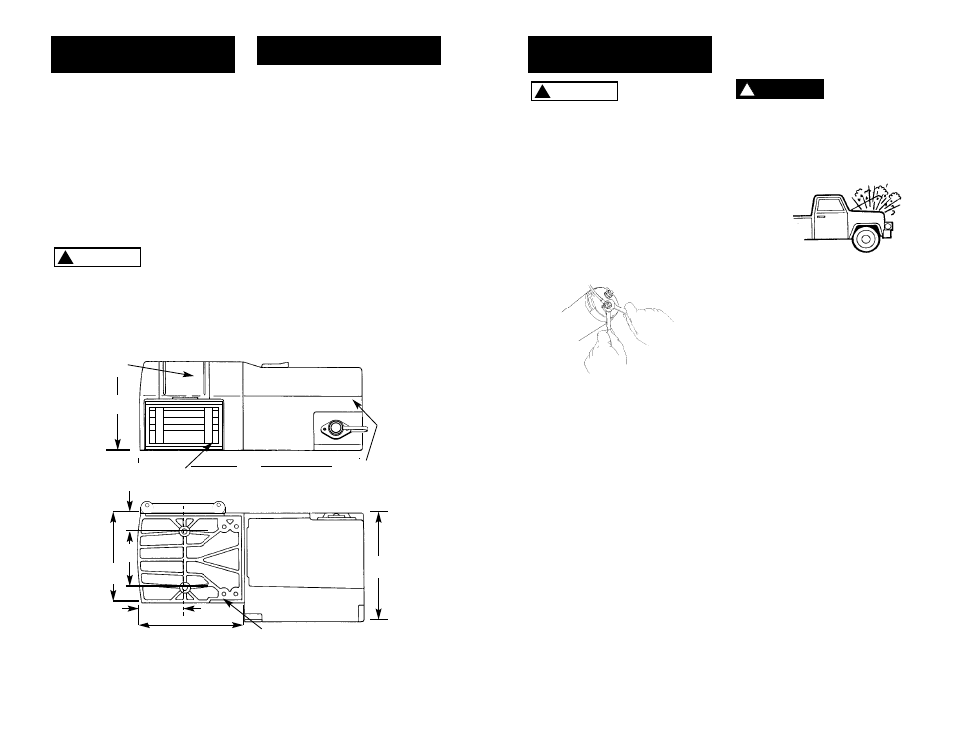

1. All dimensions are in inches [millimeters].

2. Typical mount is to flat surface capable of handling the loads. Bolts to be Grade 5 or better.

6.0

(152)

15.1

(383)

7.2

(183)

7.1

(180)

3.1

(79)

5.9

(150)

3.69

(93.7)

1.24

(31.5)

10

ROLLER FAIRLEAD

SCREWS

DRUM SUPPORT

PLATE SCREWS

MOTOR

SCREWS

DRUM SUPPORT

PLATE

Figure 9

Mount the winch to the mount that

you have designed. Mounting bolts

supplied are the

correct length for

use with up to a

1/4”(6.3 mm)

thick plate.