Operation, Air supply, Lubrication – Sunex Tools SX211A User Manual

Page 4: Troubleshooting, Limited warranty

SX211A: Parts Breakdown & Operating Manual

4

06/08/09

Operation...

Always use the recommended wheel guard to

prevent injury from broken grinding wheel parts.

If a guard has withstood a wheel breakage,

discontinue its use and replace it with a new

guard. It may be damaged. Position the guard

between the grinding wheel and the operator. Use barriers to

protect others from wheel fragments and grinding sparks.

Always wear impact-resistant eye and face

protection when involved in the operation of this

tool. Even small projectiles can injure eyes and

cause blindness. A grinding wheel that bursts can

cause very serious injury. Daily measure the air

grinder speed with a tachometer to make sure it's not greater than

the RPM marked on the grinding wheel. Never use a grinding wheel

marked with a speed lower than the air grinder speed.

Before grinding, test grinding wheel by briefly running the tool at

full throttle. Be sure to use a barrier (such as under a heavy work

table) to stop any possible broken wheel parts.

to Assemble grinding discs:

1. Use stop spanner (#53) to hold gear shaft (#33).

2. Screw on flange (#38) with shoulder side facing tool. Tighten.

3. Attach grinding disc wheel.

4. Screw on flange nut (#40), shoulder side facing tool.

Secure tightly!

Air Supply...

Tools of this class operate on a wide range of air pres sures. It is

recommended that air pres sure of these tools mea sures 90 PSI at the

tool while running free. Higher pres sure (over 90 psig; 6.2 bar) raises

per for mance beyond the rated capacity of the tool which will short en

tool life be cause of faster wear and could cause injury.

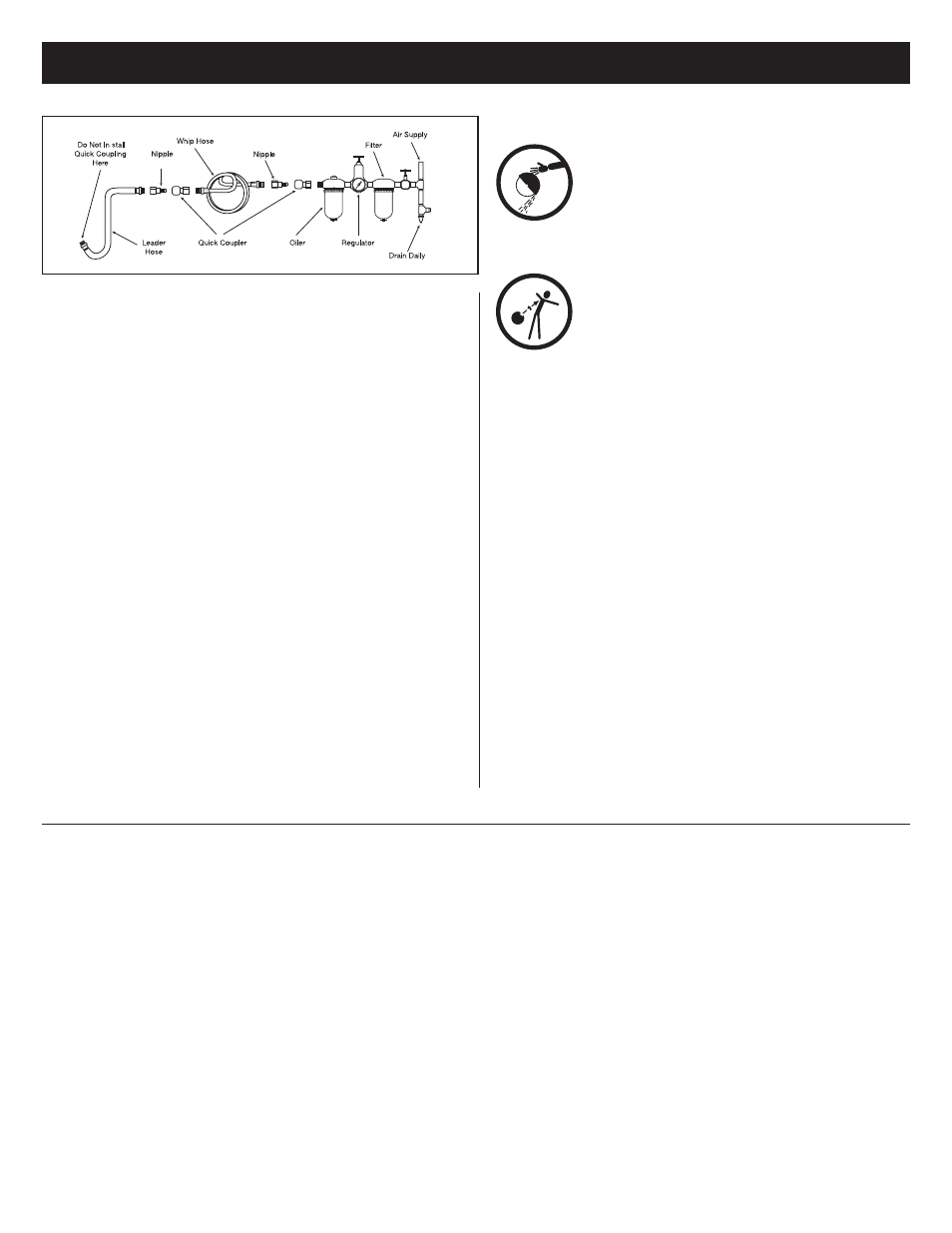

Always use clean, dry air. Dust, corrosive fumes and/or water in the air

line will cause damage to the tool. Drain the air tank daily. Clean the

air inlet filter screen on at least a weekly schedule. The rec om mend ed

hookup pro ce dure can be viewed in figure 1.

Lubrication...

Lubricate the air motor daily with quality air tool oil. If no air line oiler

is used, run 1/2 ounce of air tool oil through the tool by squirting oil

into the tool's air inlet or into the nearest connection to the air inlet,

reconnecting air supply, and then running tool. Do not use more than

1/2 ounce of oil, as overfilling will reduce the performance of the tool.

Troubleshooting...

Other factors outside the tool may cause loss of power or erratic action.

Reduced compressor output, excessive drain on the air line, moisture or

restrictions in air pipes or the use of hose connections of improper size

or poor conditions may reduce air supply. Grit or gum deposits in the

tool may cut power and may be corrected by cleaning the air strainer

and flushing out the tool with gum solvent oil or an equal mixture of

SAE #10 and kerosene. If outside conditions are in order, disconnect tool

from hose and take tool to your nearest authorized service center.

Limited Warranty...

SUNEX INTERNATIONAL, INC. WARRANTS TO ITS CUSTOMERS THAT THE COMPANY’S SUNEX TOOLS® BRANDED

PRODUCTS ARE FREE FROM DEFECTS IN WORKMANSHIP AND MATERIALS.

Sunex International, Inc. will repair or replace its Sunex Tools® branded products which fail to give satisfactory service due to defective workmanship

or materials, based upon the terms and conditions of the following described warranty plans attributed to that specific product. This product carries a

ONE-YEAR warranty. During this warranty period, Sunex Tools® will repair or replace at our option any part or unit which proves to be defective in material or

workmanship.

Other important warranty information...

This warranty does not cover damage to equipment or tools arising from alteration, abuse, misuse, damage and does not cover any repairs or replacement made

by anyone other than Sunex Tools® or its authorized warranty service centers. The foregoing obligation is Sunex Tools® sole liability under this or any implied

warranty and under no circumstances shall we be liable for any incidental or consequential damages.

Note: Some states do not allow the exclusion or limitation of incidental or consequential damages, so the above limitation or exclusion may not apply to you.

Return equipment or parts to Sunex Tools®, or an authorized warranty service center, transportation prepaid. Be certain to include your name and address,

evidence of the purchase date, and description of the suspected defect.

If you have any questions about warranty service, please write to Sunex Tools®. This warranty gives you specific legal rights and you may also have other rights

which vary from state to state. Repair kits and replacement parts are available for many of Sunex Tools® products regardless of whether or not the product is

still covered by a warranty plan.

SHIPPINg ADDRESS: Sunex Tools • 315 Hawkins Rd. • Travelers Rest, SC 29690

MAILINg ADDRESS: Sunex Tools • P.O. Box 1233 • Travelers Rest, SC 29690

Operating Instructions • Warning Information • Parts Break down