Fig. 2b – preset motor speed vs. motor load, Fig. 3b – motor speed vs. applied motor load – KB Electronics KBPC-225D User Manual

Page 8

6

II.

SETTING SPEED OR TORQUE MODE OF DRIVE (JUMPER J1)

A. Speed Control Mode – When Jumper J1 is placed in the "SPD" position the drive will

control motor speed as a linear function of the main potentiometer rotation or analog

voltage input. The range of output speed can be adjusted with the MIN and MAX trimpots.

The motor will maintain the preset speed as long as the maximum load does not exceed

the current limit set point. If the motor load exceeds the current limit setting, the Overload

LED will turn on and the motor will stall.

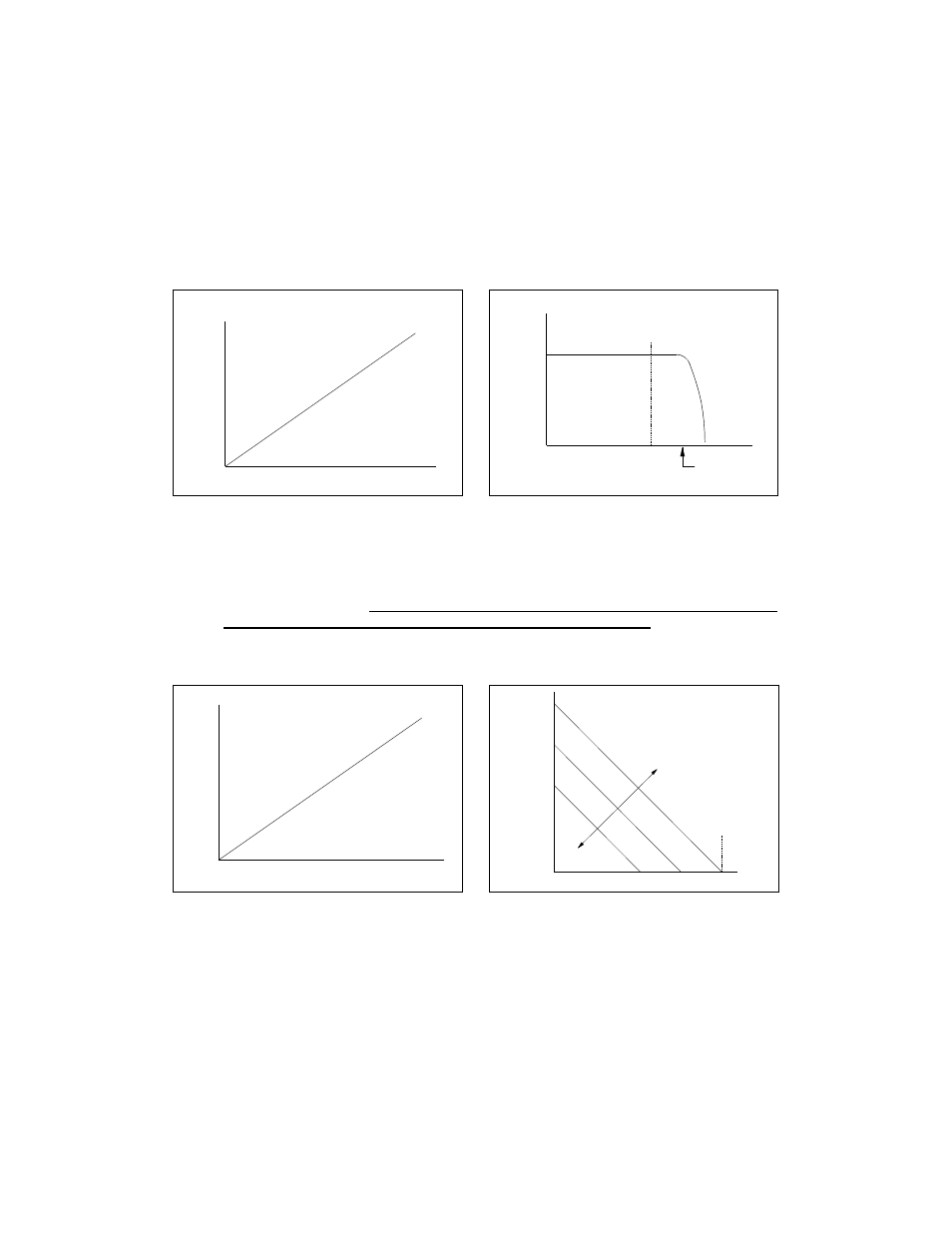

FIG. 2A – MOTOR SPEED vs.

POTENTIOMETER ROTATION

MOTOR

OUTPUT

SPEED

(%)

POTENTIOMETER ROTATION (%)

0

100

100

FIG. 2B – PRESET MOTOR SPEED vs.

MOTOR LOAD

PRESET

MOTOR

SPEED

(%)

MOTOR LOAD

100

0

150

CURRENT LIMIT STARTS

LED LIGHTS

100

B. Torque Control Mode – When Jumper J1 is placed in the "TRQ" position, the drive will

control motor torque as a linear function of main potentiometer rotation. If the motor load

exceeds the torque setting, the motor will stall, the Overload LED will light, and the drive

will apply a constant preset torque based on the potentiometer setting. The Overload LED

will light when the load torque approaches the current limit set point. The torque limits are

set via the CL trimpot. Note: When operating in the Torque Mode, Jumper J5 must be in

the "NTCL" position or drive will shut down when CL Timer times out.

FIG. 3A – MOTOR OUTPUT TORQUE vs.

POTENTIOMETER ROTATION

POTENTIOMETER ROTATION (%)

150

0

100

MOTOR

OUTPUT

TORQUE

(%)

100

FIG. 3B – MOTOR SPEED vs. APPLIED

MOTOR LOAD

100

APPLIED MOTOR LOAD (%) TORQUE

MOTOR

SPEED

(%)

HIGHER TORQUE

SETTING

TORQUE

SETTING

S3

S2

S1

LOWER TORQUE

SETTING

0

III. SETTING SELECTABLE JUMPERS

This control has selectable jumpers which can be changed to accommodate various

applications. Note: Jumpers J2 and J4 have not been installed in this control. Jumper J1

is set in accordance with Section II. Refer to Figure 1.

C. Tachometer Feedback (J3) – The control is factory set for armature feedback which

provides good load regulation for most applications. If superior load regulation is required,

tachometer feedback can provide over 1% load regulation over a 50:1 speed range. If

tachometer feedback is to be used, J3 must be placed in the "TFB" position and an external

DC tachometer must be connected. See Sections III C. (p. 7) and V E. (p. 9) for additional

information. Note: IR Comp trimpot must be turned to minimum position (full ccw).