KB Electronics KBPC-225D User Manual

Page 6

4

The electronics for the KBPC is state-of-the-art and includes short circuit and transient

protection which provides the ultimate in reliability. Electronic overload protection prevents

motor burnout and demagnetization of PM motors. The control can be operated in either the

Speed or Torque mode via jumper selection.

Standard features include electronic start/stop and an LED indicator array for Power On, Stop

and Overload.

Although the KBPC is factory set for most applications, a variety of trimpots allow adjustment

of the following parameters: Minimum and Maximum Speed, Acceleration, Deceleration,

Current Limit, IR Comp, and Timed Current Limit. Optional features offered are: Run-Stop-Jog,

and Input Signal Isolation.

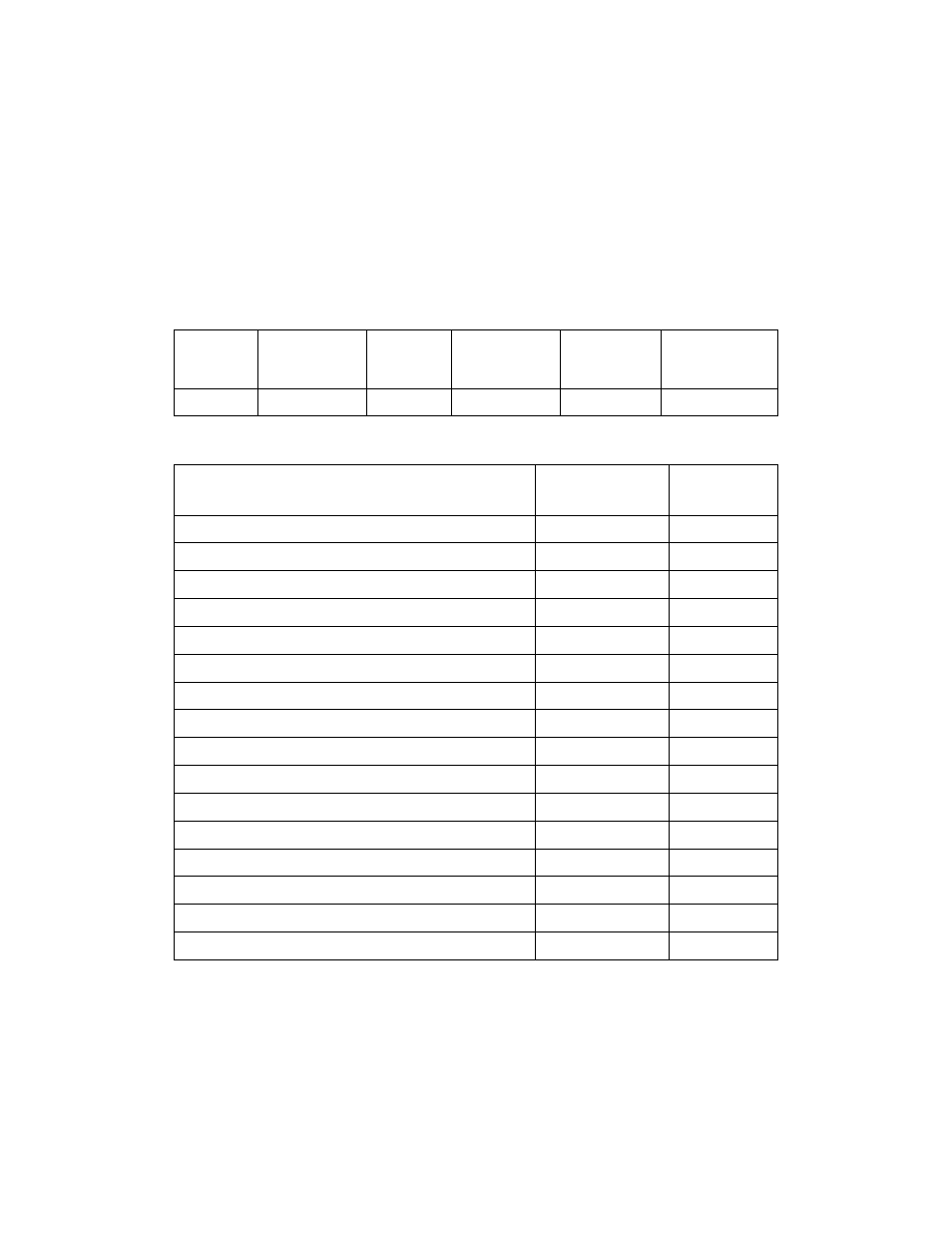

TABLE 1 – ELECTRICAL RATINGS

Model

Number

Input Line

Voltage

(VAC-50/60Hz)

Armature

Voltage

(VDC)

Maximum Ac

Load Current

(RMS Amps)

Maximum DC

Load Current

(DC AMPS)

Maximum

Power HP (KW)

KBPC-225

230

0 – 200

22.0

15

3 (2.25)

TABLE 2 – KBPC-225 GENERAL PERFORMANCE SPECIFICATIONS

PARAMETER (units)

SPECIFICATIONS

FACTORY

SETTING

AC Line Input (VAC ± 15%, 50/60 Hz)

230

—

Horsepower at 230 VAC Line (HP) [KW]

3 [2.25]

—

Armature Voltage Range at 230 VAC Line (VDC)

0 - 200

(1)

180 VDC

Field Voltage at 230 VAC Line (VDC)

200/100

(2)

—

Ambient Temperature Range (ºC)

0 - 45

—

Speed Range (Ratio)

50:1

(3)

—

Load Regulation [Armature Feedback] (% Base Speed)

±1

—

Load Regulation [Tachometer Feedback] (% Set Speed)

±1

—

AC Line Voltage Regulation ( % Base Speed)

±0.5

—

ACCEL and DECEL Ranges (Seconds)

0.1 - 15

1

MIN SPEED Range ( % Base Speed)

0 - 30

0

MAX SPEED Range (% Base Speed)

60 - 120

90

IR COMP Range at 230 VAC Line (VDC)

0 - 30

8

CL Range ( % Range Setting)

0 - 180

150

Timed CL Range (Seconds)

0.5 - 15

7

Voltage Following Linearity (% Base Speed)

±0.5

—

Notes:

(1)

Maximum recommended output voltage is 180 VDC at 230 VAC. Exceeding this output

voltage will cause a reduction in load regulation performance.

(2)

For shunt wound motor with lower field voltage, use F1 and L1 connection.

(3)

Consult motor manufacturers for constant torque speed range of motor. (Typical speed

range for most 3 HP motor is 20:1)