F. auxiliary piping, Part 5 - hydronic piping – HTP PHE199-119 User Manual

Page 19

19

LP-314 REV. 3.24.14

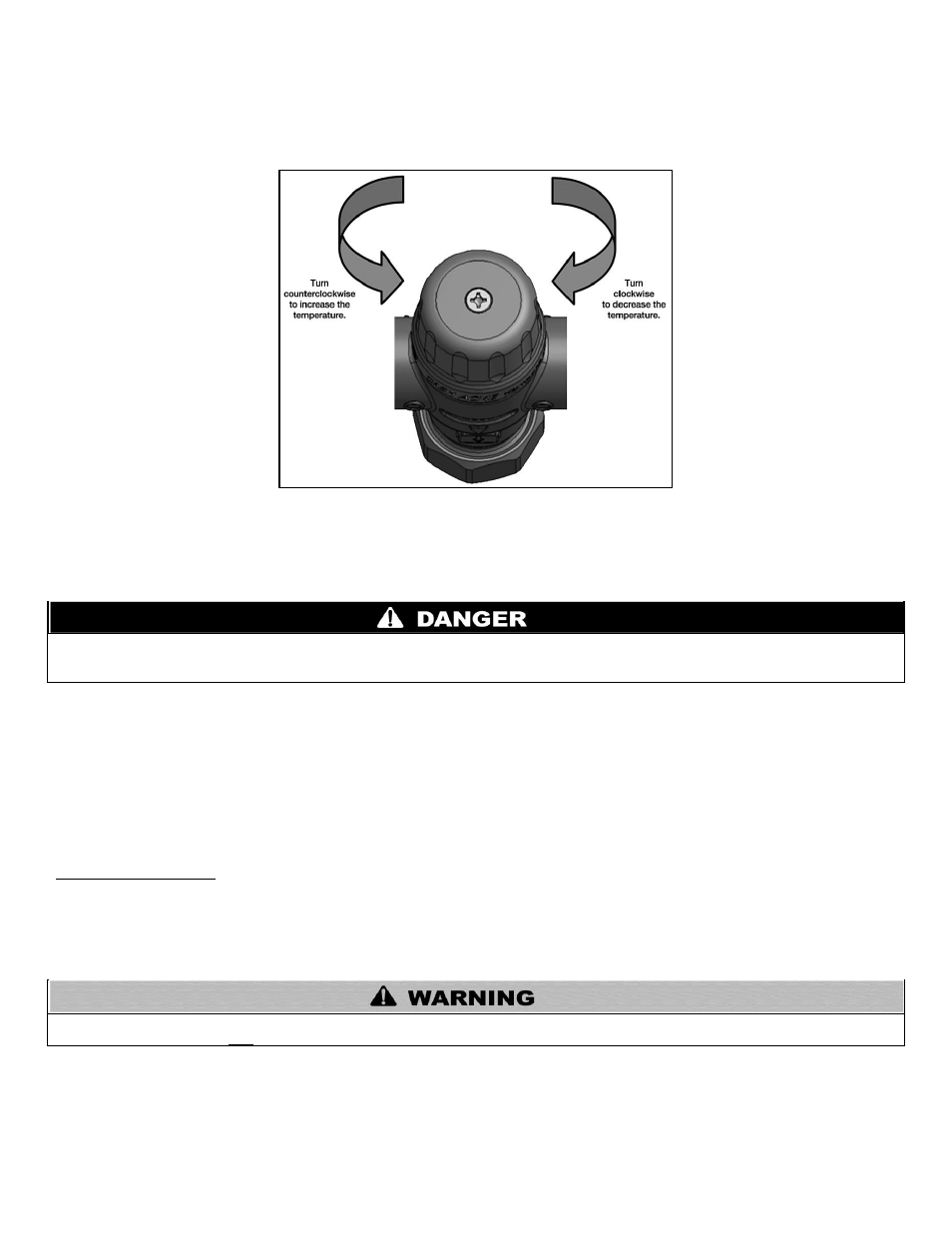

Setting the Mixing Valve Outlet Temperature

1. Turn both the hot and cold water supplies on. Open an outlet, preferably a sink or basin faucet rather than a shower. To calibrate, let

water run for 2 minutes and measure the outlet temperature with a thermometer. Adjust the green cap counter clockwise to increase

temperature and clockwise to decrease temperature, as shown in Fig. 4.

Figure 4

– Adjusting the Mixing Valve

2. Once the desired outlet temperature has been achieved, refit the green top so that it snaps onto the body of the mixing valve.

NOTE: See the instruction sheet included with the mixing valve to adjust the maximum temperature of the mixing valve greater than

120

o

F.

Hotter water increases the risk of scald injury. Scalding may occur within 5 seconds at a setting of 140

o

F (60

o

C). Water temperature

over 125

o

F can instantly cause severe burns, or death, from scalds. Children, disabled, and elderly are at the highest risk of being

scalded. See instruction manual before setting temperature at appliance. Feel water before bathing or showering!

MIXING VALVE MAINTENANCE AND SERVICE

It is recommended to check the mixing valve annually to ensure proper system capabilities. More frequent checks are

recommended in adverse water conditions.

When checking the mixed water supply temperature, use the same faucet used in the initial installation temperature

adjustment.

There may be some variation in the water temperature from the mixing valve due to seasonal temperature variations in the

cold water supply.

If the water supply is of poor quality, the internal components may jam, requiring an additional filter or strainer to be fitted to

the system. Contact a plumbing professional for appropriate materials and installation.

F. AUXILIARY PIPING

Auxiliary connections are provided to connect to an air handler, plate exchanger or other additional devices. Auxiliary ports can also be

used for recirculation line connections. These connections must be installed in accordance with all local and national codes or any

applicable prevailing standards. A

uxiliary connections are 1” on all models. Never use dielectric unions or galvanized steel fittings. Use

only copper or brass fittings. Teflon sealant must be used on all connections. The top port has a dip tube that draws hot water from the

dome of the unit and the bottom port dip tube returns the water to bottom of the unit.

Never connect auxiliary connections to any system that uses glycol or other solutions formulated for hydronic systems. These auxiliary

connections are to be used only in a potable water system. Failure to follow this warning could result in death or serious injury.