C. domestic water piping, D. appliance piping, E. mixing valve installation – HTP PHE199-119 User Manual

Page 17

17

LP-314 REV. 3.24.14

Never use dielectric unions or galvanized steel fittings on any domestic water or auxiliary connections. Use only copper or brass fittings.

Thread sealant must be used on all connections.

C. DOMESTIC WATER PIPING

Domestic water connections must be installed in accordance with all local and national plumbing codes or any applicable prevailing

standards. The appliance is supplied with a rated mixing valve certified to ASSE 1017. You must completely follow the instructions

included with the mixing valve for proper installation. This mixing valve must be installed on the domestic outlet to assure that hot water

temperature does not vary more than +/

– 5°F, as the unit adjusts its stored water automatic set point to meet the requirements of the

hydronic heating module. The valve MUST NOT be allowed to freeze. If the mixing valve is installed in a potentially freezing situation,

suitable insulation must be fitted to prevent damage. DO NOT use excess thread sealant (in liquid, tape or other form) as this may

cause the mixing valve to fail. Toxic chemicals shall not be introduced into the mixing valve system.

Recommend to the user that the mixing valve be checked annually to ensure its continued function.

D. APPLIANCE PIPING

The domestic inlet and outlet ports on the appliance

are 1” NPT connections. We recommend the installation of shut-off valves and

unions on both the inlet and outlet ports to isolate the appliance for future service.

It is important that the connections on the inlet and outlet are brass or copper. Never use dielectric unions or galvanized steel fittings.

Teflon thread sealant must be used to seal all tank connections. An approved ASSE 1017 mixing valve is provided with every appliance

and must be installed on the outlet to protect the user from scalding temperatures. This valve reduces the point of discharge

temperature by mixing the hot and cold water from the discharge outlet or mixed outlet port. This device alone will not protect the user

from scalding temperature. To install and set up the mixing valve, follow the pre-installation steps in this manual and also follow the

enclosed instructions included with the mixing valve.

E. MIXING VALVE INSTALLATION

The mixing valve provided with this appliance must be installed on the hot water outlet connection to reduce the risk of scalding. This

mixing valve only reduces the risk of scalding injury.

1. All installations must be carried out by licensed

professionals.

2. The installer must ensure compatibility of all

installations. Example: Temperature of hot water

–

marked “H”, cold water inlet – marked “C”, and mixed

outlet

– marked with directional arrow.

3. The mixing valve may be installed in any position.

4. Local codes shall take priority over any inconsistency

in these instructions.

5. During startup, you must

ensure that the valve is set to

the desired temperature (the

mixing valve preset is 120

o

F).

If the valve temperature needs

to be adjusted, please refer to

the mixing valve instructions and/or the following settings.

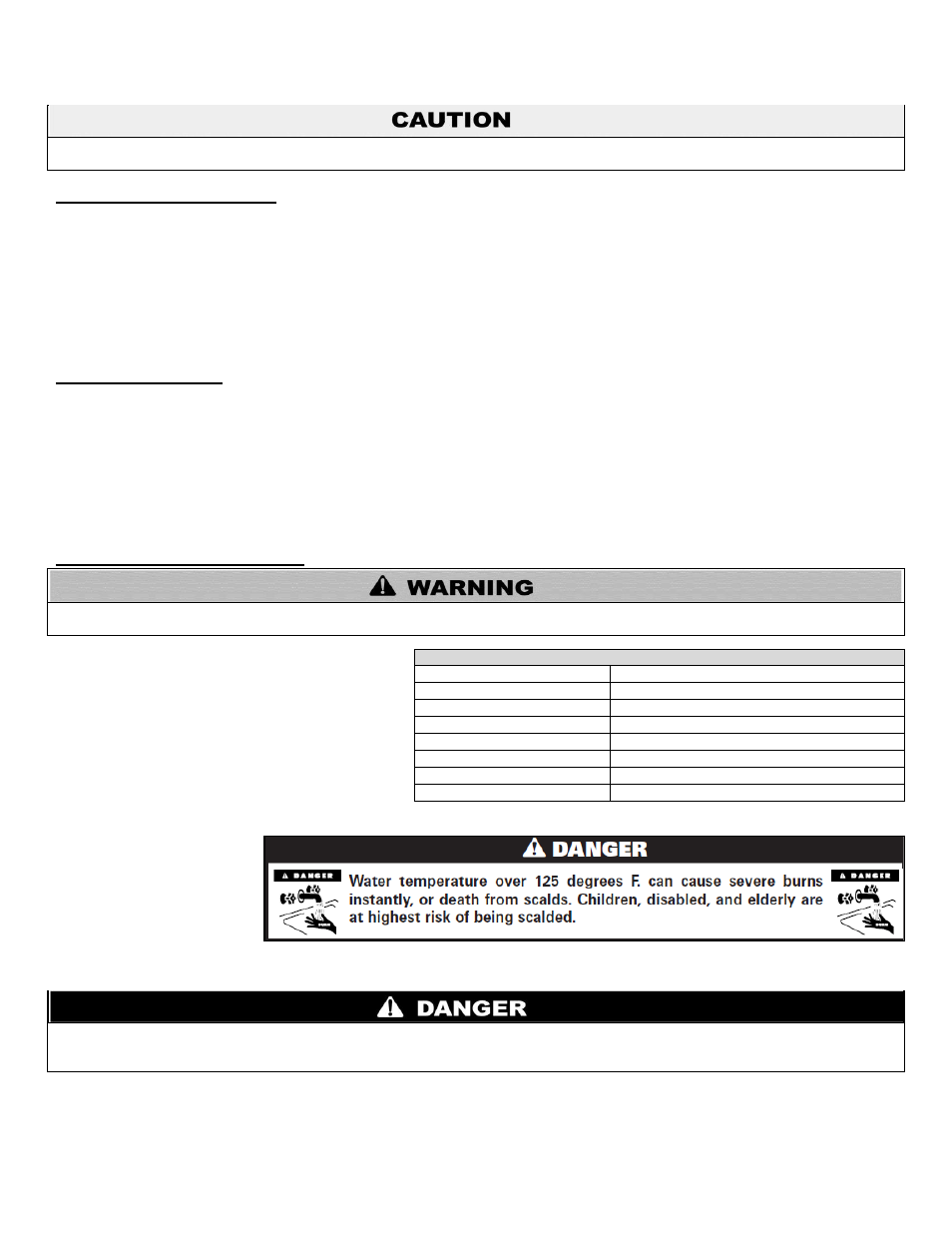

Hotter water increases the risk of scald injury. Scalding may occur within 5 seconds at a setting of 140

o

F (60

o

C). Water temperature

over 125

o

F can instantly cause severe burns, or death, from scalds. Children, disabled, and elderly are at the highest risk of being

scalded. See instruction manual before setting temperature at appliance. Feel water before bathing or showering!

APPROXIMATE TIME / TEMPERATURE RELATIONSHIPS IN SCALDS

120

o

F

More than 5 minutes

125

o

F

1 ½ to 2 minutes

130

o

F

About 30 seconds

135

o

F

About 10 seconds

140

o

F

Less than 5 seconds

145

o

F

Less than 3 seconds

150

o

F

About 1 ½ seconds

155

o

F

About 1 second

Table 2