Separating the connectors – Harwin Z80-299 User Manual

Page 3

IS-30 Issue: 2 Date: 22.09.10 C/Note: 10949

Page 3 of 4

DE-LATCHING TOOL Z80-299

Separating the Connectors

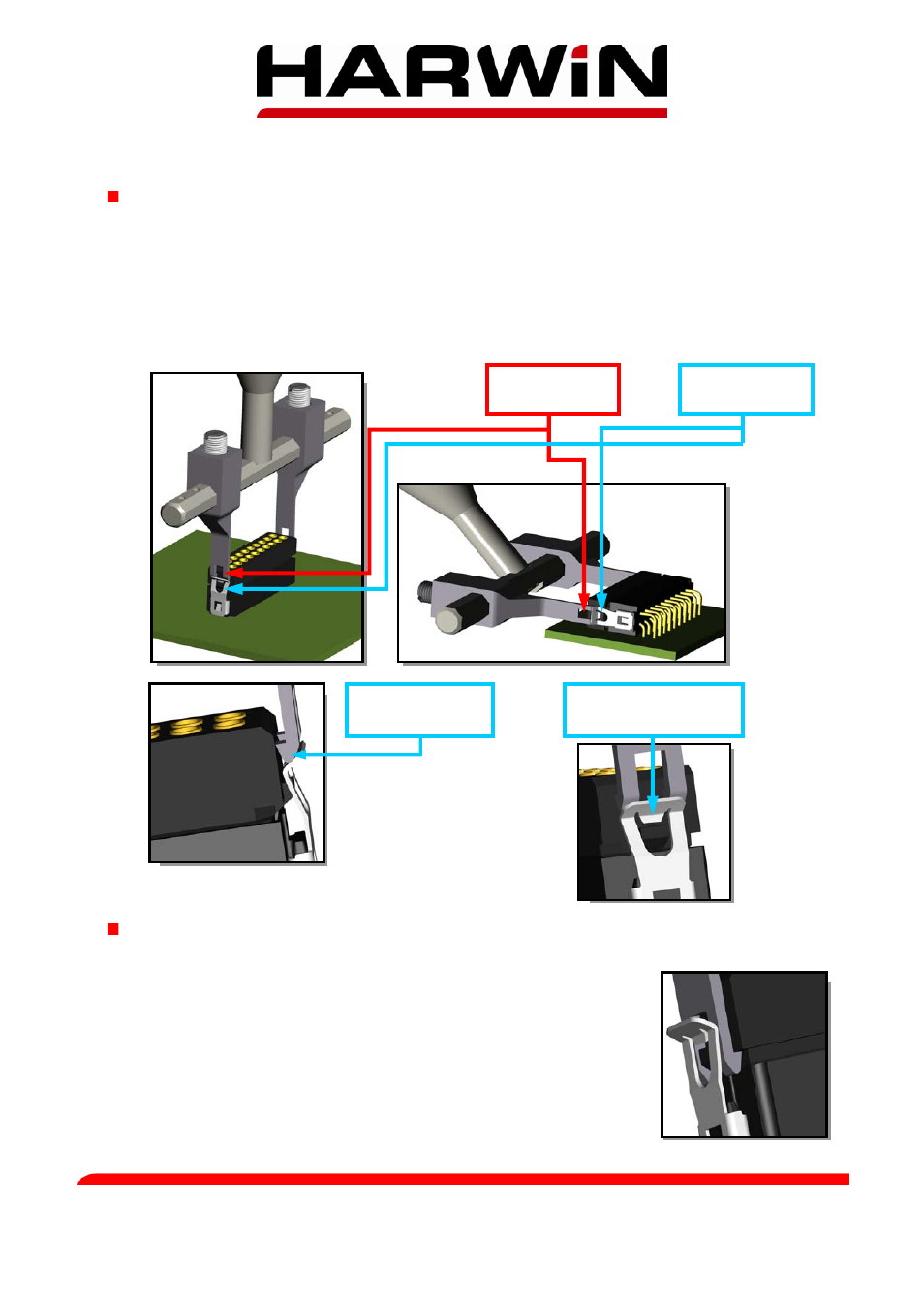

The pictures below show the 60mm long multi-positional bar being used to separate both vertical

and horizontal DIL connectors. Shown below is a 20 way connector, with the tool in the “Ready”

position, prior to separating the connectors.

Both jaws must be centrally positioned, resting the tool on the two latches.

The multi-positional bar must be kept parallel to the moulding at all times to prevent breaking

the latches.

Square Cut outs in the jaws must be aligned to clear the “Clip” feature of the latches /

mouldings when pushed onto connector.

Once correctly positioned the tool can then be pushed on until the hook features of the jaws grip

the female moulding.

The picture on the right shows how the tool should look once engaged

ready to separate mated connectors.

Harwin North America

Harwin Europe

Harwin Asia

T: +1 603 893 5376 F: +1 603 893 5396

T: +44 (0) 23 9231 4545 F: +44 (0) 23 9231 4590

T: +65 6 779 4909 F: +65 6 779 3868

E: [email protected] W: www.harwin.com

E: [email protected] W: www.harwin.com

E: [email protected] W: www.harwin.com.sg

“Clip” feature Close up

Square cut outs

“Clip” feature

“Ready” position