General information, Crimping procedure – Harwin Z22-020 User Manual

Page 2

GENERAL INFORMATION

The Z22-020 Hand Crimp Tool consists of a ratchet mechanism hand tool and a set of jaws. The jaws

comprise of upper and lower crimp dies.

The contact is correctly crimped when the tool is free to open at the fully closed position, i.e. when the

ratchet releases.

CRIMPING PROCEDURE

1.

Ensure that the wire to be crimped is within the specified range of sizes for the contact and the crimp

tool. Failure to use the specified wire size will result in poor quality crimps and possible tool damage.

Wire Gauge

Minimum pull-off force (Newtons)

30 AWG

6N

28 AWG

11N

26 AWG

18N

24 AWG

29N

2.

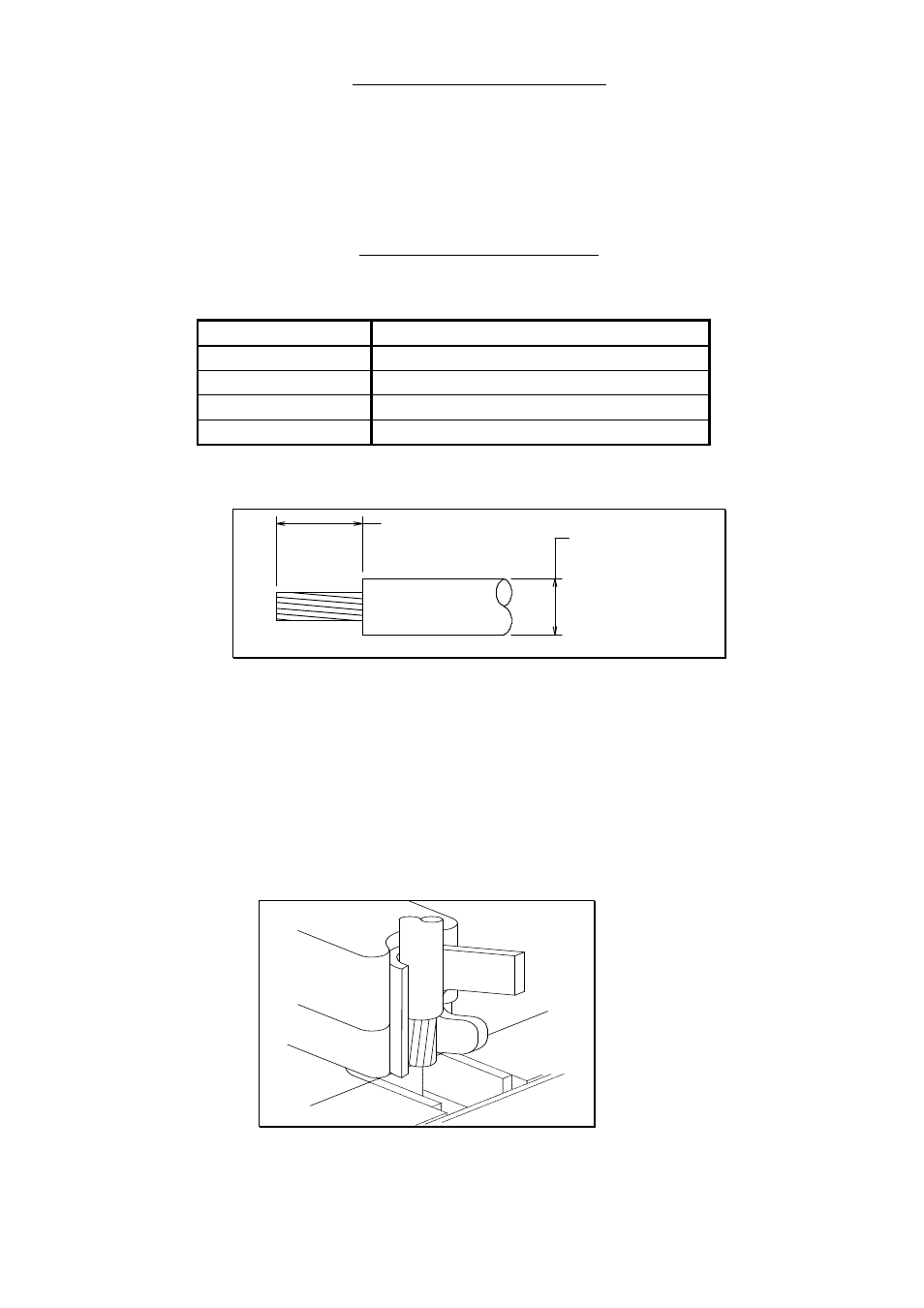

Strip the wire insulation to the dimensions shown below. Care should be taken to avoid cutting or

displacing the conductors. If the conductors are displaced, they may be re-aligned with a gentle twist.

1.0 – 1.5mm (M22-304/5)

1.5 – 2.0mm (M22-306/8)

Ø1.4mm max

3.

Make certain that the hand crimp tool is in the fully open position, and that the jaws are free from dirt

and debris.

4.

If the socket is on a reel, break or cut off a contact from the strip of bandolier.

5.

Place the contact into the correct crimp cavity in the fixed jaw. The markings on the jaw indicate the

correct crimp cavity according to the wire size being used. The orientation of the contact is with the

crimp end uppermost, with the open side of the crimp facing towards the moving jaw.

6.

Partially close the crimp tool until the wire stop comes across the face of the fixed jaw.

7.

Take the pre-stripped wire and insert it into the contact so the conductors and insulation are

positioned in the crimp. The conductors should be touching the wire stop.

8.

Keeping the cable steady in the crimp, fully close the hand crimp tool until the ratchet releases. Let

the crimp tool open.

9.

After crimping remove the assembly. The process is then repeated for each crimp required.

IS-05 Issue: 4 Date: 09.06.10 C/Note: 10764

Page 2 of 3