Harrington Hoists and Cranes SMR Trolley User Manual

Page 29

29

5.7

Inspection Methods and Criteria

5.7.1

This section covers the inspection of specific items. The list of items in this section is based on those

listed in ANSI/ASME B30.16 for Frequent and Periodic Inspection. In accordance with ANSI/ASME

B30.16, these inspections are not intended to involve disassembly of the trolley. Rather, disassembly

for further inspection would be required if frequent or periodic inspection results so indicate. Such

disassembly and further inspection should only be performed by a qualified person trained in the

disassembly and re-assembly of the trolley.

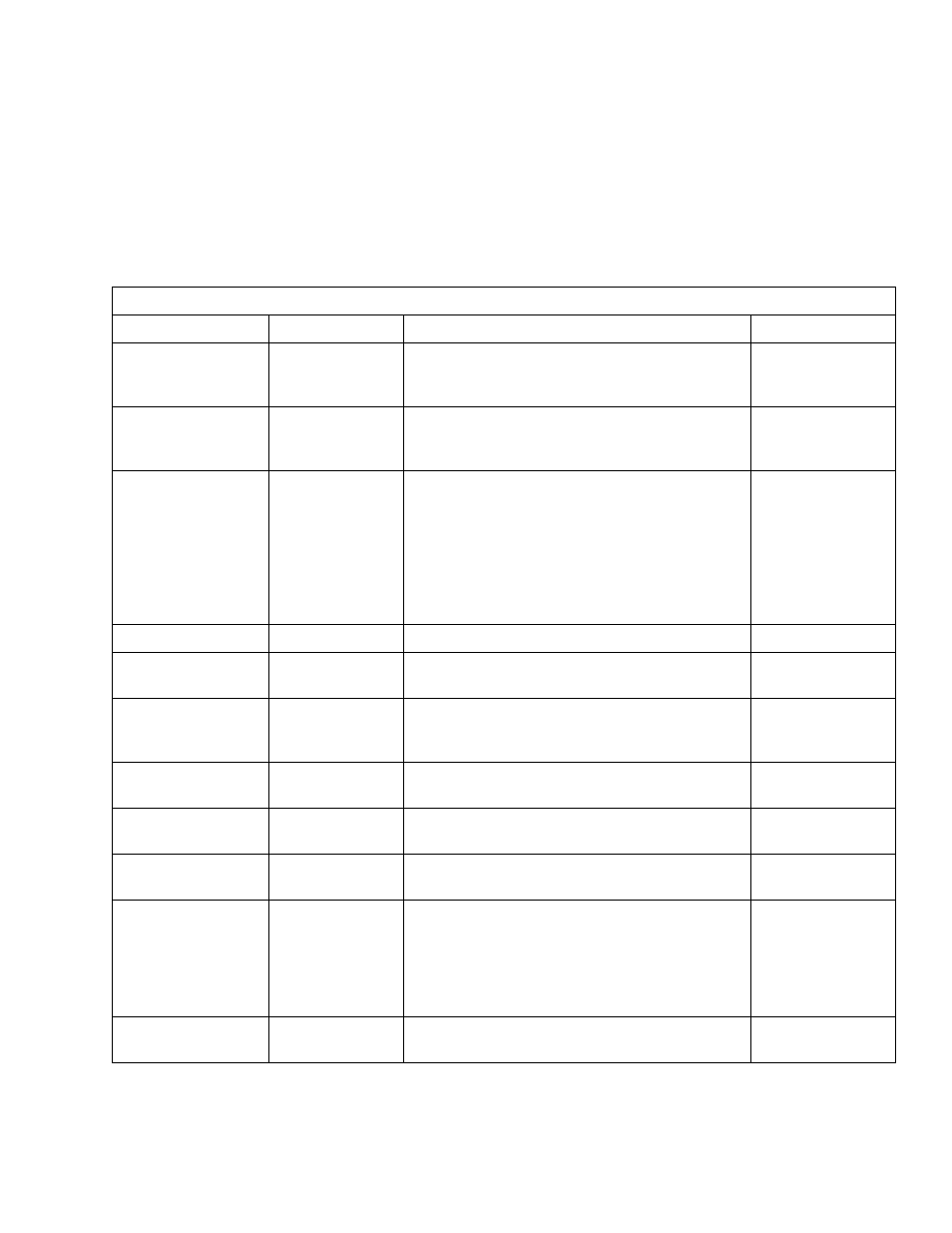

Table 5-3

Trolley Inspection Methods and Criteria

Item

Method

Criteria

Action

Functional operating

mechanisms.

Visual, Auditory

Mechanisms should be properly adjusted and

should not produce unusual sounds when

operated.

Repair or replace

as required.

Braking System

Operation

Function

Trolley must come to a smooth stop within 10% of

its traveling speed when the pendant button is

released.

Repair or replace

as required.

Housing and

Mechanical

Components

Visual, Auditory,

Vibration,

Function

Trolley components including, suspension shafts,

track wheels, track wheel axles, clevises,

connection yokes, suspension bolts, shafts, gears,

bearings, pins, rollers, and bumpers should be free

of cracks, distortion, significant wear and

corrosion. Evidence of same can be detected

visually or via detection of unusual sounds or

vibration during operation.

Replace.

Side Plates

Visual

Must be free of significant deformation

Replace.

Bolts, Nuts, Snap

Rings, and Split Pins

Visual, Check

with Proper Tool

Bolts, nuts, snap rings and split pins should not be

loose.

Tighten or replace

as required.

Track Wheel - Tread

Visual, Measure

Diameter of the inside and outside tread surface

should not be less than the discard value shown in

Table 5-4

.

Replace.

Track Wheel - Gear

Visual

Teeth should not be cracked, damaged, or

excessively worn.

Replace.

Side Rollers - Wear

Visual, Measure

Diameter should not be less than the discard value

shown in

Table 5-5

.

Replace.

Suspension Shaft

Visual, Measure

Suspension shaft should not be bent. Diameter

should not be worn by 10% or more.

Replace.

Motor Brake

Visual, Measure

Brake lining dimension “A” should not be less than

discard value listed in

Table 5-6

. Refer to

Section

6.2

for gaining access to motor brake and

inspection procedures. Braking surfaces should

be clean, free of grease/oil and should not be

glazed.

Replace.

Contactor Contacts

Visual

Contacts should be free of significant pitting or

deterioration.

Replace