Connecting the pump, Measuring the flow – SKC 303 Film Flowmeter User Manual

Page 2

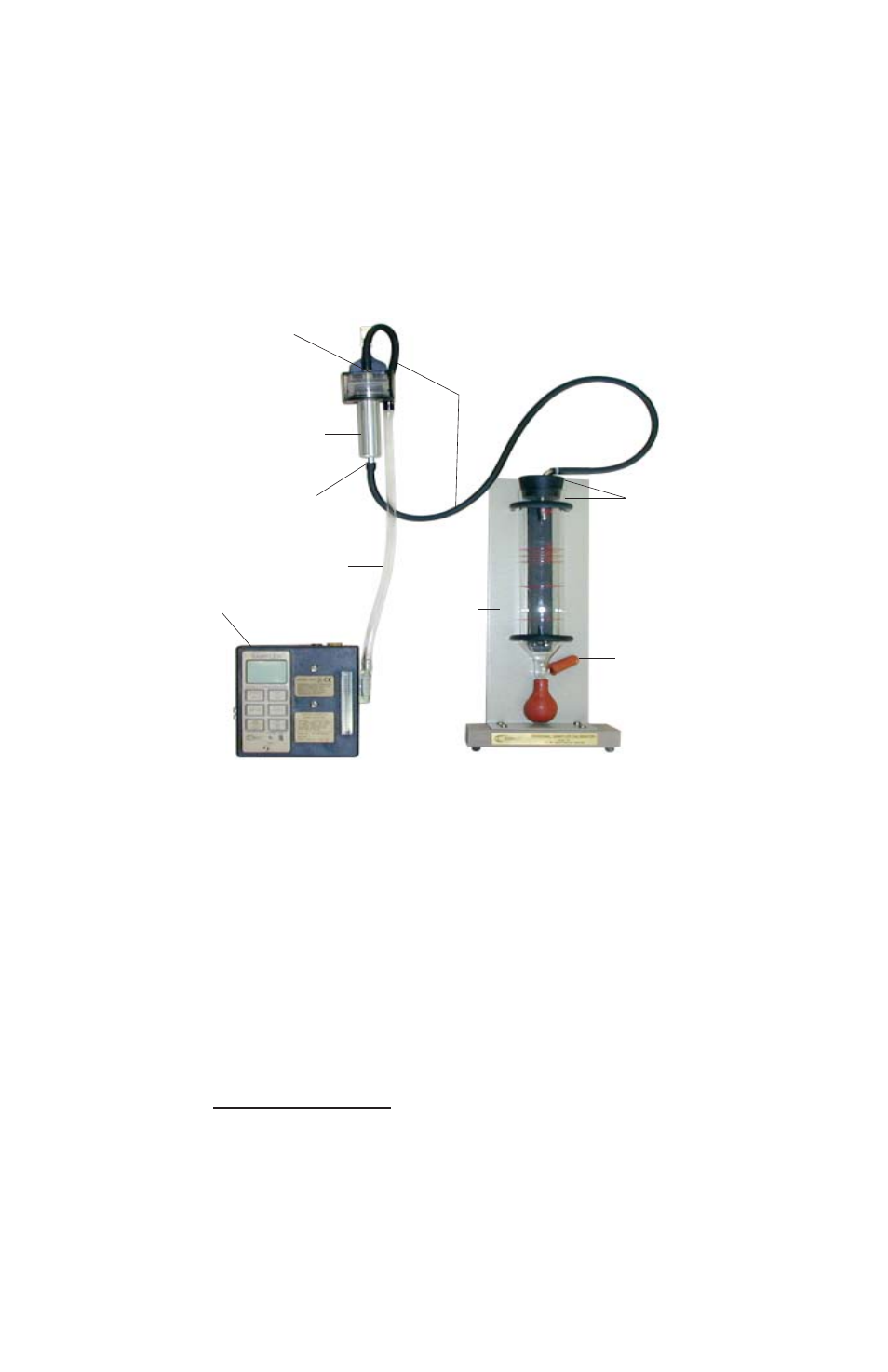

Connecting the Pump

Note: If the pump to be calibrated draws air, connect it to the rubber tubing on the fl owmeter’s

top rubber stopper. If the pump blows air, use rubber tubing to connect it to the lower side

arm near the base of the fl owmeter.

1. Remove the rubber cap from the side arm inlet near the base of the fl owmeter.

2. Using rubber tubing, connect one end to the appropriate port on the fl owmeter and the

other end to the inlet of the sampling medium to be used (if applicable).

3. Using fl exible tubing, connect the outlet of the sampling medium to the inlet of the

pump.

Measuring the Flow

1. Turn on the pump.

2. Squeeze the rubber bulb on the fl owmeter to force the liquid above the inlet. Bubbles

(fi lm) will form.

3. Using a stopwatch, start timing the fi lm as it passes the zero line and stop timing as the

bubble reaches the 100 ml line. For best results, form several bubbles, fi ve to six seconds

apart, and time the last bubble.

Caution: Do not squeeze the bulb continuously. This causes froth to form on the walls mak-

ing timing diffi

cult.

The fl ow rate can be determined from the Flow Chart on the back page, or calculated using

the following equation:

Flow (ml/min) = 60 x (volume traveled)

Time (in seconds)

Outlet

(upper

port)

Inlet (lower

side arm port)

Pump

inlet

Calibration

chamber

Tygon

tubing

Sample

pump

Flowmeter

Rubber

tubing

Sample

media

outlet

Inlet