Securitron BPS-24-2, 3, 4, 6 AND 10 User Manual

Page 5

PN# 500-10300

Page 5

Rev. D, 04/11

the emergency release terminals are opened, battery power will, however, be blocked just as

normal power from the power supply would be.

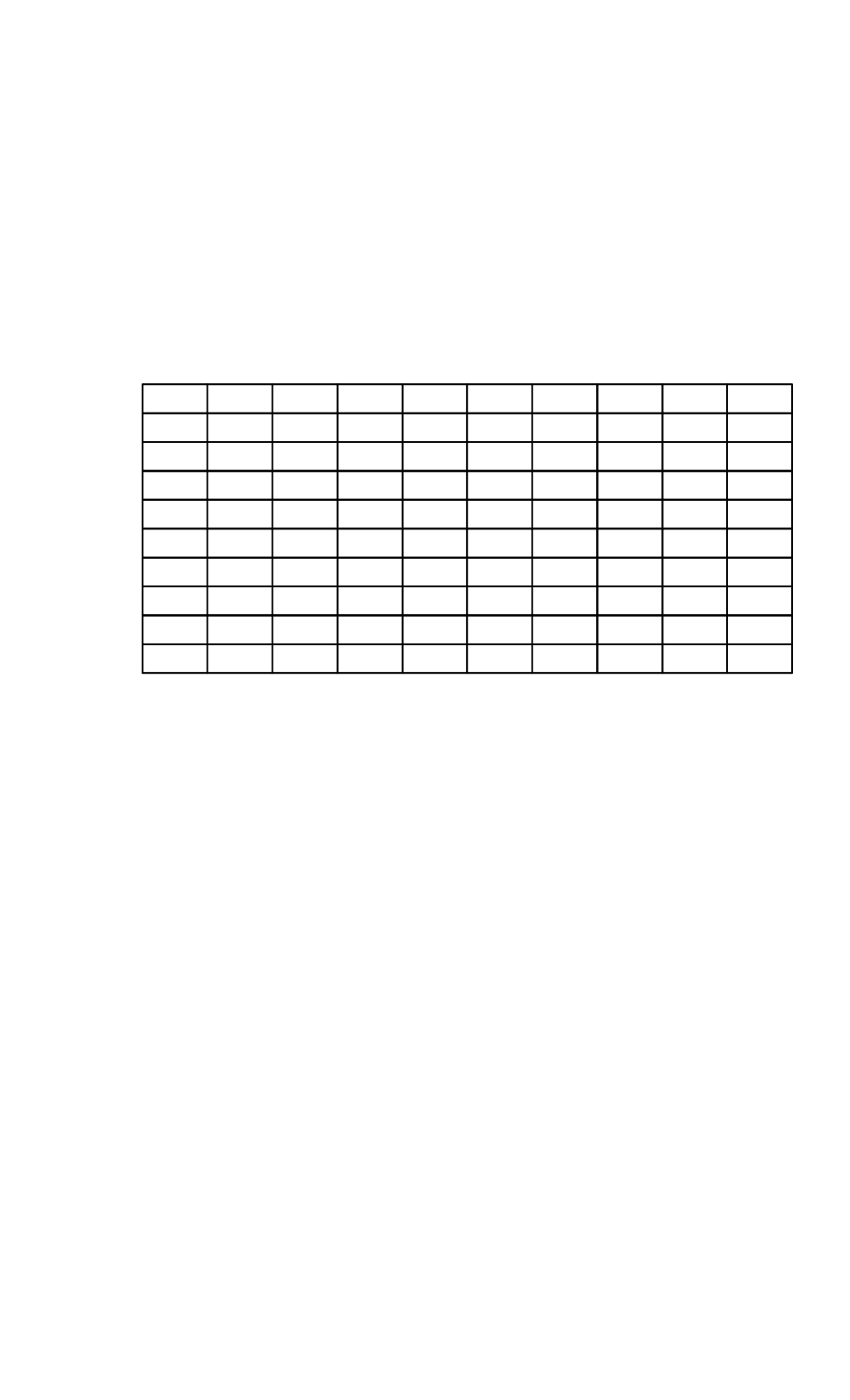

The components utilized on the CCS board for battery charging function for battery packs up to

20 amp hours in capacity whether 12 or 24 volts. Larger battery packs can be handled but

Securitron must be informed so that the board may be modified. Consult (Figure 3) to calculate

the correct battery pack based on desired backup time and the current drawn by the load. For

proper battery charging, the power supply must be set at 27 volts for a 24 volt system,

and 13.5 volts for a 12 volt system. Securitron power supplies are factory set to this level

and if it is not maintained, the batteries will not hold their full capacity, and may even be

damaged.

FIG 3: CHART TO DETERMINE SIZE OF BATTERY PACK

MIN

1 HR

2 HR

4 HR

8 HR

16 HR

24 HR

48 HR

72 HR

UL STD.

150 MA

300 MA

500 MA

1 A

2 A

3 A

4 A

5 A

7.5 A

10 A

4 AH

4 AH

4 AH

4 AH

4 AH

4 AH

4 AH

4 AH

4 AH

4 AH

4 AH

4 AH

4 AH

4 AH

4 AH

4 AH

4 AH

4 AH

4 AH

4 AH

4 AH

4 AH

4 AH

4 AH

4 AH

4 AH

4 AH

4 AH

8 AH

8 AH

8 AH

8 AH

8 AH

8 AH

12 AH

16 AH

20 AH

12 AH

12 AH

16 AH

16 AH

20 AH

16 AH

20 AH

12 AH

20 AH

12 AH

20 AH

12 AH

20 AH

8 AH

8 AH

12 AH

12 AH

16 AH

16 AH

24 AH

36 AH

24 AH

24 AH

36 AH

28 AH

28 AH

24 AH

36 AH

48 AH

36 AH

44 AH

72 AH

100AH

24 AH

32 AH

40 AH

60 AH

72 AH

52 AH

72 AH

84 AH

130AH

180AH

48 AH

72 AH

100AH

120AH

180AH

240AH

48 AH

100AH

150AH

200AH

240AH

360AH

480AH

72 AH

150AH

240AH

300AH

360AH

480AH

720AH

BACKUP TIME DESIRED

TOTA

L

CU

R

R

EN

T D

R

AW

N

"MIN" TIME REFERS TO FACILITY USING A GENERATOR WHERE THE BATTERIES

ARE ONLY REQUIRED TO OPERATE THE SYSTEM FOR A FEW MINUTES

U.L. STANDARD REQUIRES 4 HOURS OF BATTERY OPERATION FOLLOWED BY

A 24 HOUR RECHARGE PERIOD AND THEN A SECOND 4 HOURS OF OPERATION

STANDARD SECURITRON POWER SUPPLIES CAN ONLY CHARGE UP TO A 20AH PACK.

MODIFIED EQUIPMENT. LARGER PACKS ARE SHOWN IN ITALICS IN THE CHART.

IF A LARGER PACK IS CALLED FOR, THE FACTORY MUST BE ALLERTED TO SUPPLY

BATTERIES MUST BE SEALED LEAD ACID OR GEL CELL TYPES.

DRY CELLS WILL NOT RECHARGE AND WILL BE DAMAGED.

THIS CHART IS ONLY VALID IF BATTERIES ARE OPERATED

AT ROOM TEMPERATURE. IN A COLD ENVIRONMENT, CAPACITY IS REDUCED.

BATTERIES SHOULD BE REPLACED AFTER 5 YEARS OF USE.

3.7 CODE APPROVED WIRING METHODS

Note that these units are Class 2 rated. This means that the individual DC outputs of the

supplies (on “P” terminals) are current limited and can pose neither a high voltage nor high

energy hazard outside of the enclosure. Electrical building codes in most jurisdictions permit

Class 2 wiring to be done “in the open” rather than in conduit. To maintain the Class 2

ratings on the “P” terminal outputs, never connect them together to obtain higher capacity.

If you require higher capacity use the “H” terminal but the “H” terminal is high current (not Class

2) and generally must be in conduit. The line voltage wiring coming into the unit also must

generally be in conduit as it poses a high voltage hazard. Be sure to check with your local

building department to make sure you are complying with applicable wiring codes before

installing these units.

4. SLAVE BOARD

Your power controller may include more than one CCS board. If so, the other boards will be

"slave" boards (part # CCB-8) whose only purpose is to provide eight additional "P”, and "R"