Ronan X90 Series User Manual

Page 14

12.0 LEAK TEST PROCEDURES FOR

SEALED SOURCES

12.1 Ronan Leak Testing Service

The NRC requires that all sealed sources be tested

for leakage at specified intervals. Only Kr-85,

tritium and certain sources of very small activity (10

CFR 30.18a) are exempted from leak testing.

Ronan Engineering provides for users’ convenience

and safety the “Leak Testing Service.” The leak

testing procedure detailed in these instructions

applies only to the Ronan Model WK Leak Testing

Kit supplied with the Ronan Leak Testing Service.

The Ronan Model WK Leak Testing Kit is intended

for use on all sealed sources that are not exempt

from testing.

This service may be purchased from Ronan on a

contract basis for five years when wipe testing at

six-month intervals is required or on a one-time

basis in the case of three-year wipe test intervals.

The service must be purchased for each individual

source. If the service is retained, Ronan will send

the required number of leak test kits, consisting of:

a) A cotton swab (“Q-tip”) saturated in radiac

wash, contained in a small plastic tube.

b) Special instructions on its use.

c) Leak test forms.

After the sealed sources have been wiped by the

materials, issue a report based on the results and

forward a copy of the results to the customer

immediately.

12.2 Using the Leak Test Kit:

For instructions on using the Leak Test Kit see

section 11.8.4 for well sources or section 11.9.2 for

standard sources.

Return the shipping tube, prepaid, via United

Parcel Services (UPS). Do not send the shipping

tube via conventional mail, as postal regulations

prohibit mailing of radioactive material in this form.

Upon receipt of the wipe, Ronan will perform a

sensitive analysis to determine the presence of

radioactive material. If the wipe is contamination-

free, a notice will be sent via mail that the source is

leak-free. If radioactive material exceeding .005

microcuries is detected on the wipe, an emergency

notification will be sent via telegram or telephone,

advising that the source holder must be taken out

of service and sent back for repair. The emergency

notification will contain detailed instructions for

removal and shipment of source holder.

Ronan will maintain records of each leak test

analysis performed. The records will include the

name and address of the customer; the date the

sample was collected; the individual collecting the

sample; the person performing the analysis; the

date the analysis was performed; the unique

identification of the source being tested; the

radioactive material and mass number contained in

the source; and the results of the test expressed in

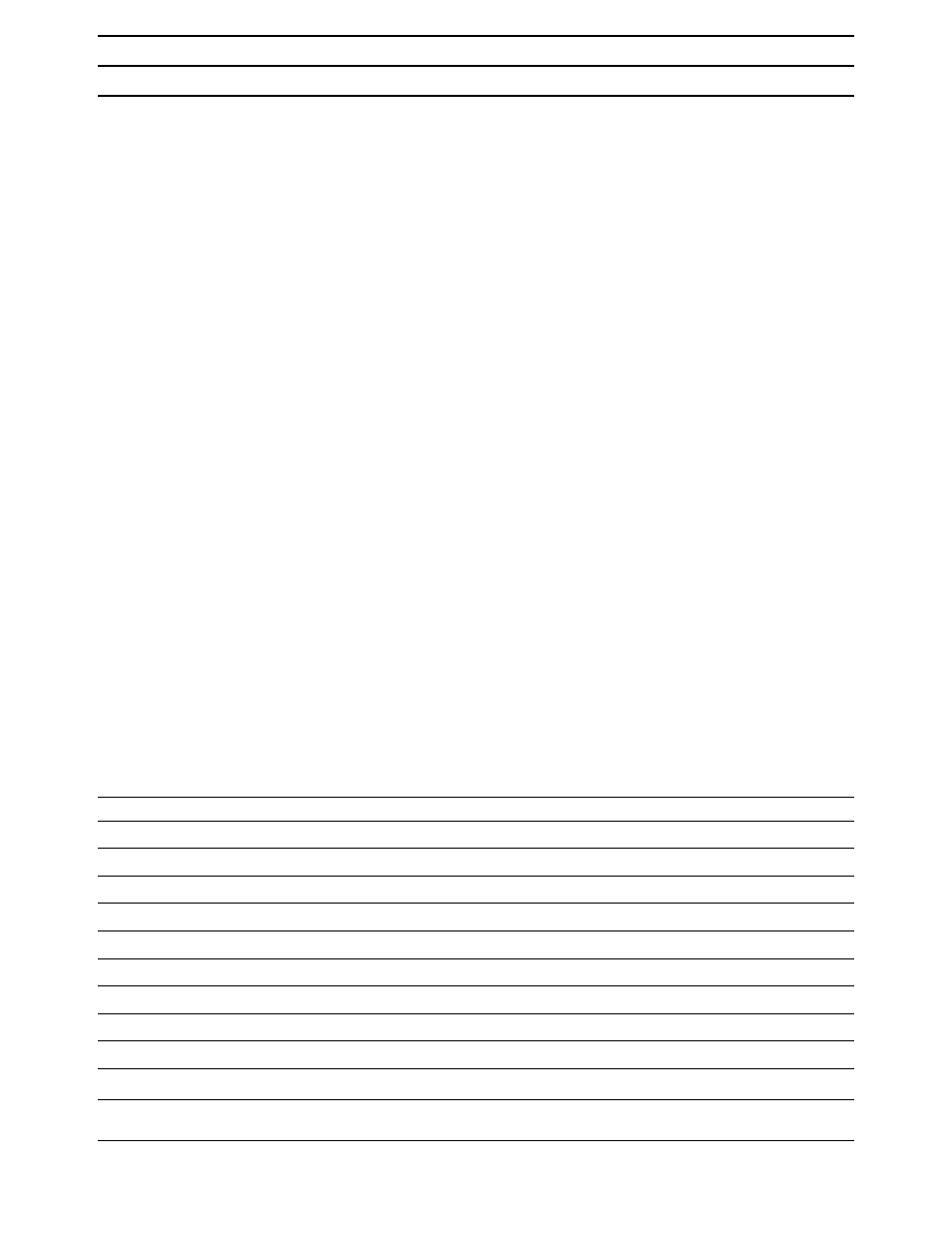

PARTS LIST—SERIES X90 POINT LEVEL MONITOR

Item

Qty.

ID

Part No.

Description

Vendor

1

1

R1

RC20GF105J

Resistor, Carbon, ½ W, 5%, 1.0 Meg

Allen-Bradley

2

1

R2

RC20GF335J

Resistor, Carbon, ½ W, 5%, 3.3 Meg

Allen-Bradley

3

1

R3

RC20GF225J

Resistor, Carbon, ¼ W, 5%, 2.2 Meg

Allen-Bradley

4

1

R4

RC20GF203J

Resistor, Carbon, ¼ W, 5%, 20 k

Allen-Bradley

5

1

R5

RC20GF183J

Resistor, Carbon, ¼ W, 5%, 18 k

Allen-Bradley

6

1

R6

RC07GF104J

Resistor, Carbon, ½ W, 5%, 100 k

Allen-Bradley

7

1

C1

DPMS-6D5

Capacitor, 5000 pFd, 600 Vdc

CDE

8

1

Q1

2N4392

Transistor, N-CH JFET

National

9

1

Q2

2N6725

Transistor, NPN Darlington

National

10

1

Circuit Board

CCI

11

2

350-1300-11-07-

Terminal

Cambion

X90-1004 or X90-1004X Probe