Rivers edge® spin shot – Rivers Edge RE637 Spin Shot User Manual

Page 6

Check for parts online at

www.HuntRiversEdge.com or call 800-450-EDGE (3343) M-F 8-5

6

Operator's Manual

Rivers Edge® Spin Shot™

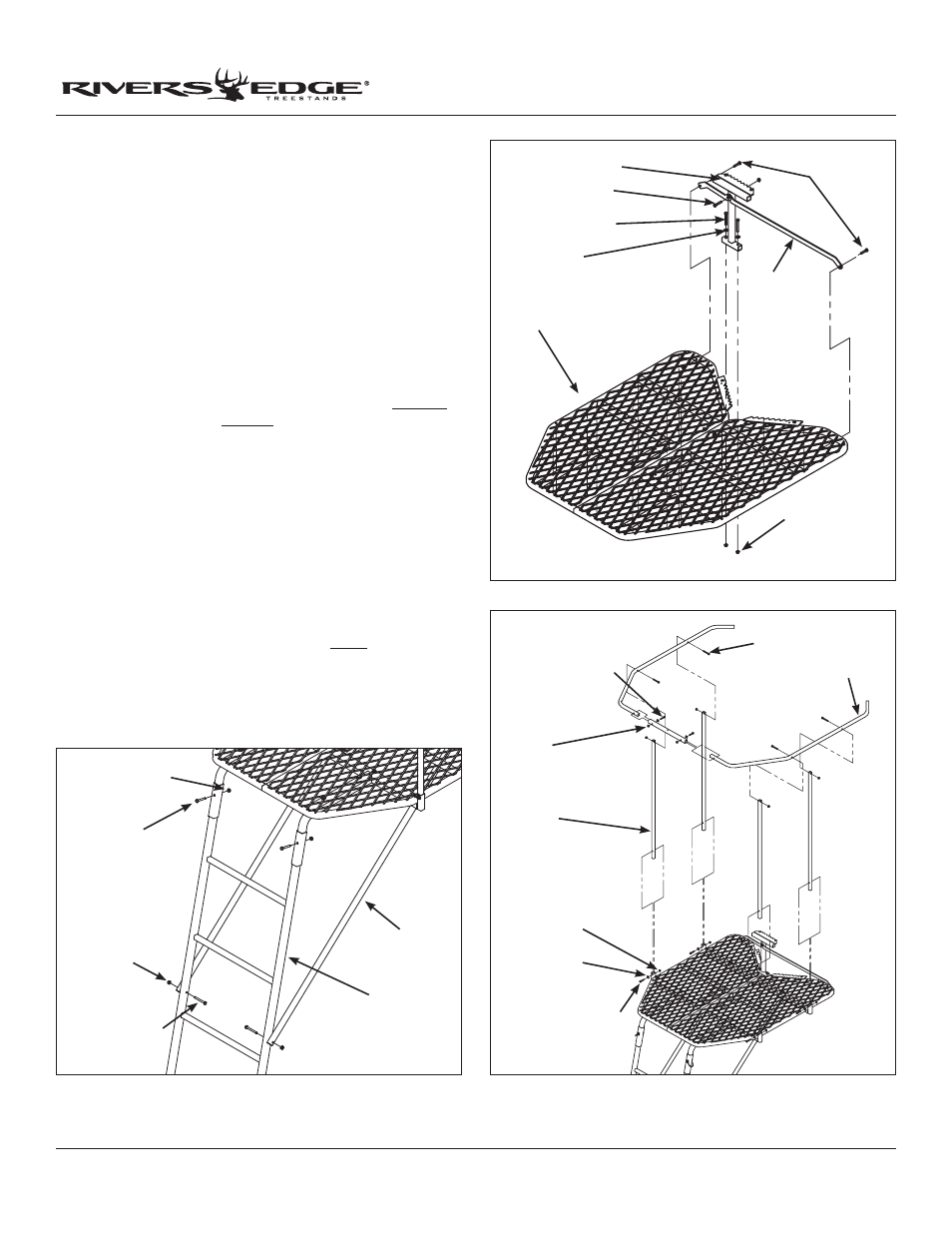

5. Insert the two ladder receiver J-pipes (already assembled onto the

platform) into the pockets of the top ladder section with side holes

(SL78). Attach the (2) support tubes (112ML75) to the outside of top

ladder section using (2) provided 1/4-20 x 2-1/4” bolts and locknuts.

Secure the top ladder section and assembled top platform section

together using (2) provided 1/4-20 x 1-3/4” bolts and locknuts.

SEE FIGURE 3

6. Attach the tree blade weldment (112ML73) to the top side of

assembled platforms (near welded on platform tree blades) using

(2) provided 1/4-20 x 2-1/4” bolts, locknuts and steel washers.

SEE FIGURE 4

NOTE: Teeth of tree blade weldment should point to the rear of

assembled platforms, in the same direction as platform tree

blades.

7. Attach (2) tree blade support braces (112ML76) to the front side of

tree blade weldment and back side of the assembled platforms using

(3) 1/4-20 x 1-1/2” bolts and (3) locknuts. SEE FIGURE 4. Pay special

attention to the orientation of the support braces shown in

FIGURE 4.

8. Using the end with the greater distance from hole to end of tube,

insert (4) shooting rail uprights (112ML72) into pockets of platform

spanner tubes. Secure each upright in the pocket using (4) 1/4-20

x 1-1/4” bolts, locknuts and steel washers. SEE FIGURE 5

9. Insert (2) curtain/shooting rail rims (112ML71) into each end of the

rail spanner tube (TWR26) and secure using (2) provided 1/4-20 x

1-1/4” bolts, locknuts and steel washers. SEE FIGURE 5. Pay special

attention to the orientation of shooting rail rims in FIGURE 5.

10. Attach the assembled shooting rail to the inside of shooting rail

uprights using (4) provided 1/4-20 x 1-3/4” bolts & locknuts. SEE

FIGURE 5. You must now tighten all nut & bolt assemblies. Be

sure not to over tighten or crush tubing when tightening!

FIGURE 3

support tube

top ladder section

1/4-20 x 2-1/4"

bolt

1/4-20 x 1-3/4"

bolt

locknut

locknut

1/4-20 x 1-3/4" bolt

1/4-20 x 1-1/4" bolt

locknut

locknut

steel washer

1/4-20 x 1-1/4"

bolt

shooting rail

upright

shooting rail rim

FIGURE 5

1/4-20 x 1-1/2"

bolts

tree blade

support bracket

tree blade weldment

1/4-20 x 2-1/4" bolt

steel washer

1/4-20 x 1-1/2" bolt

assembled platforms

locknut

FIGURE 4