General Tools and Instruments RLD400 User Manual

Page 6

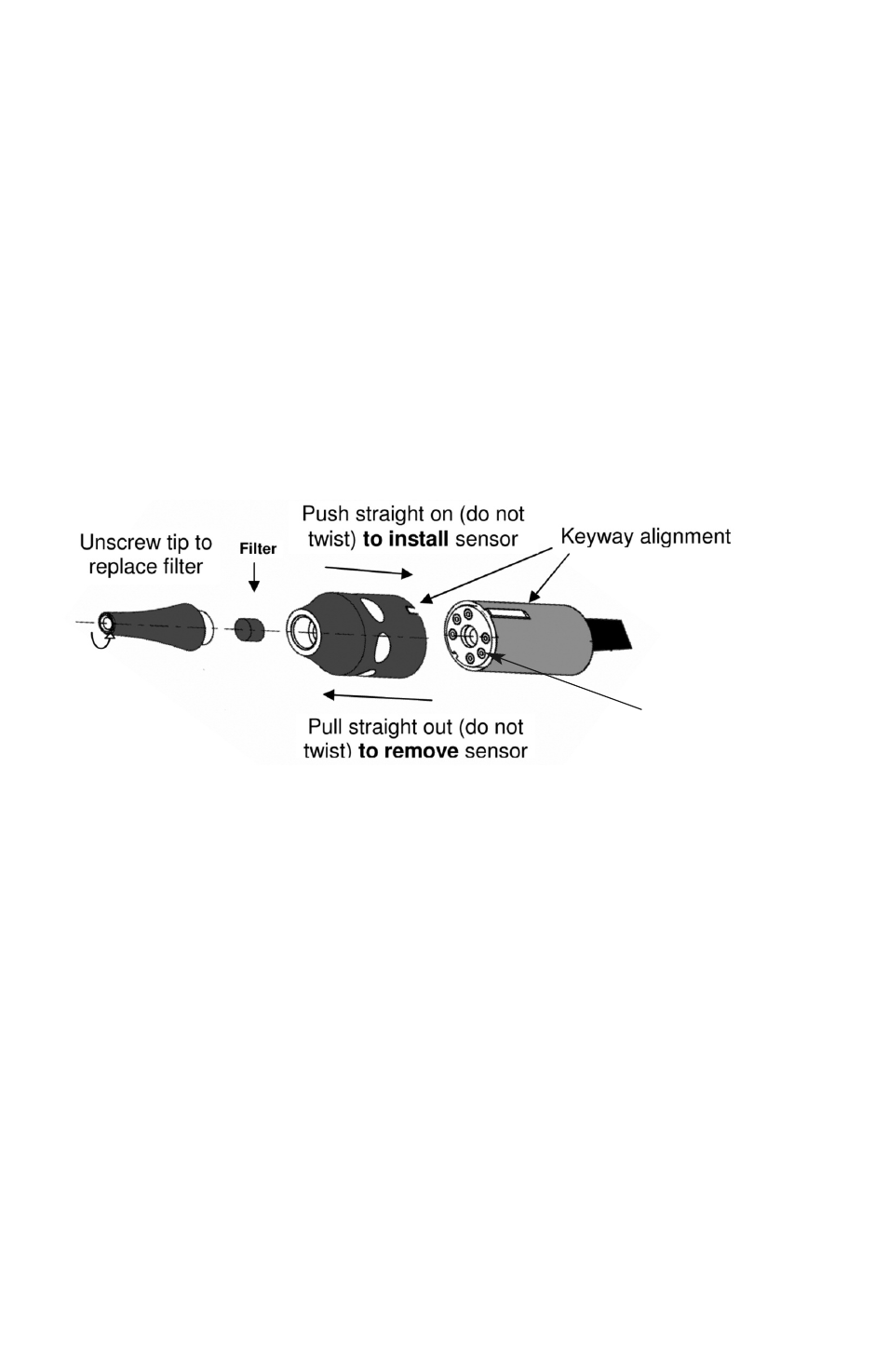

IMPORTANT: The startup sequence will not execute to completion if the refrigerant gas

sensor cannot be heated. That would be the case if the sensor becomes electrically

disconnected from the probe.

The sensor (which is under the black probe tip assembly) is physically and electrically

connected to the probe by a six-pin socket visible under the clear plastic near the red

“refrigerant detected” LED near the end of the probe (see figure below).

If the startup sequence fails to complete after 60 seconds, abort the process by

powering off the unit. Then check the integrity of the connection between the sensor and

the probe by doing the following:

1) Pull the black probe tip assembly straight out and away from the sensor socket

without twisting it. This disconnects the sensor.

2) Line up the keyway notch on the probe tip assembly with the raised keyway on the

sensor socket holder

3) Carefully push the sensor back into the socket without forcing or twisting it;

misalignment can damage the sensor’s pins. This reconnects the sensor.

CHECKING FOR LEAKS

Position the end of the RLD400’s flexible-obedient probe—which retains its configured

shape—close to any suspected source of leaking refrigerant gas. In a vehicle, wet oily

areas around hose connections and fittings, and greasy streaks radiating outward

around the compressor clutch or on the underside of the hood just above the

compressor are telltale signs of a leak. Another place to check sooner rather than later

is the evaporator (located inside the heater/defroster plenum under the dash).

Whenever the sensor at the end of the probe senses a refrigerant gas that it has been

designed to detect:

1) The red LED at the end of the probe will begin flashing much faster than three times

every two seconds

2) The beeper will increase its own frequency correspondingly

3) A number from 1 to 9 will appear in the digital leak size indicator window.

6

Sensor socket and

red “refrigerant

detected” LED