General Tools and Instruments 860 v.1 User Manual

Page 4

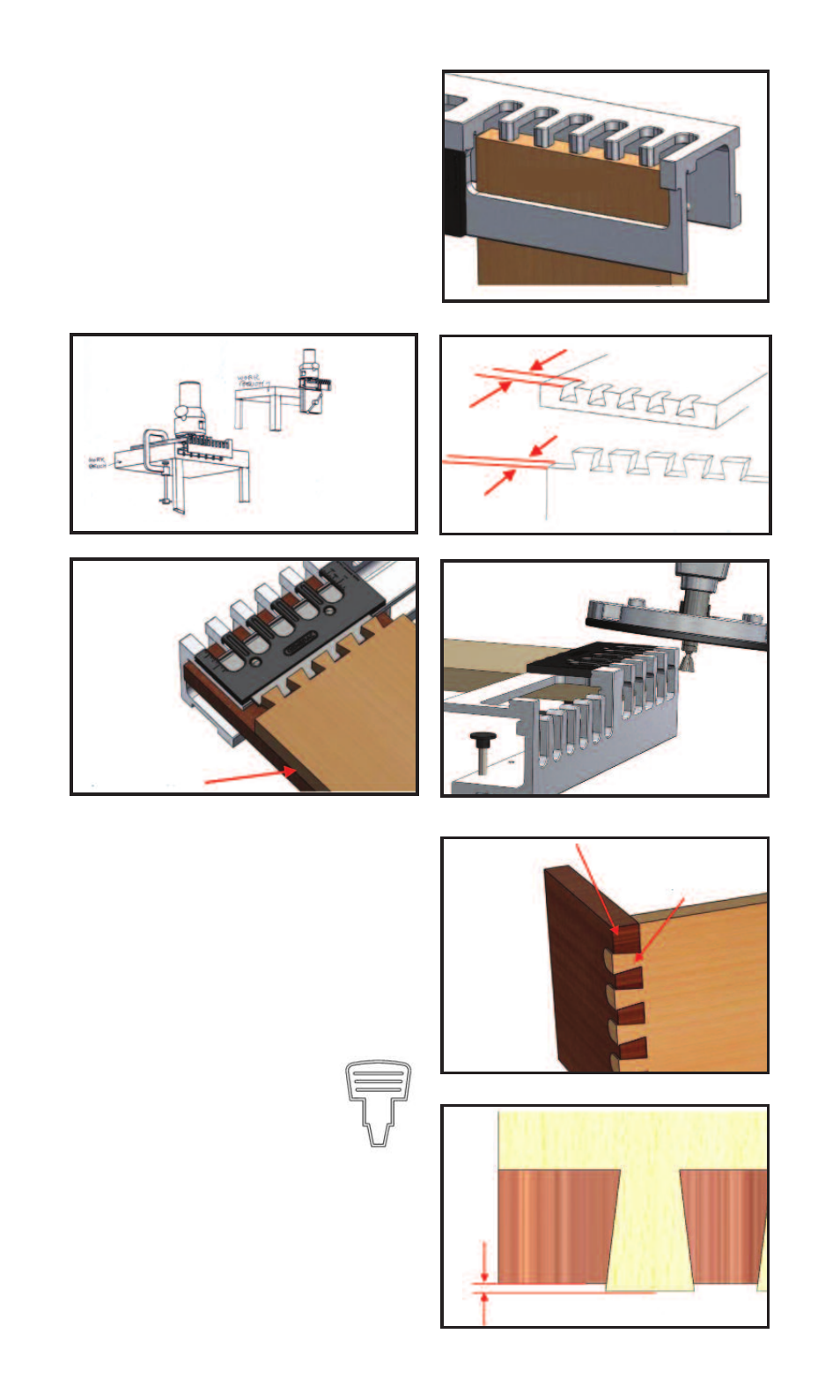

10. Loosely clamp the “PINS” wood into the jig with the outside face

pointing inward.

11. Insert the “TAILS” from previous cut into the teeth on the bottom of

adjuster plate. Position the wood to be cut by lining up the sides

with the first piece. (FIG. 13)

12. With the edges of both boards aligned; tighten the thumbscrews

(NOTE THE CAUTION FROM STEP #5) and secure the stock to the

bench. Remove the “TAILS” board before proceeding.

13. Make all cuts. For this cut the router should ride on the surface of

the depth plate as shown in FIG. 14. Be sure to follow the jig profile

as the slots are wider than the cutter bearings. This is to allow for

a rough and a finish pass.

14. Before gluing, fit the two sections together. The joint should be

tight and even with no gaps. If problems arise, file or trim the

joint to improve the fit.

CUTTING A FULL THROUGH DOVETAIL JOINT

*This requires a dovetail cutter bit with a depth greater than

the wood you are cutting.

The steps required to cut a full through joint (FIG. 15) are very similar

to those described in the previous section CUTTING A HALF BLIND

DOVETAIL JOINT, with the following exceptions:

1. When cutting the “TAILS” (FIG. 15) portion of the joint, set the bit

depth to slightly greater than the thickness of the “PINS” board.

This will ensure that the tails are slightly proud when fit and can

be sanded down for a flush fit. (FIG. 16)

2. When cutting the “PINS” portion of the joint, set the cutter depth

deeper (tighter) first and adjust to the desired joint fit.

CUTTING JOINTS WIDER THAN 6"

Joints over 6" wide must be cut in multiple

segments. To align the jig with the previous cut,

the aligning tool must be used.

1. Move the wood in the jig and position the last slot from the

previous cut in the last channel of the jig.

2. Loosely clamp the wood in the jig.

3. Insert the aligning tool into the slot to properly center the wood

with the jig. (FIG. 17)

4. Tighten the thumbscrews, (CAUTION: DO NOT OVERTIGHTEN),

and continue cutting.

5. Repeat as necessary.

FIG. 10

INSIDE FACE

FIG. 12

FIG. 11

FIG. 13

SIDES LINE UP

FIG. 14

FIG. 15

TAILS

PINS

FIG. 16

4