He series, General pump – General Pump HE User Manual

Page 7

GENERAL PUMP

A member of the Interpump Group

HE SERIES

Page 7

9. PUMP INSTALLATION

9.1 Positioning

The pump should be installed flat on a rigid base by

means of the four M14 threaded feet. The base should

be rigid enough to avoid any misalignment of flexing of the

pump/transmission coupling axis due to the torque

involved during operation.

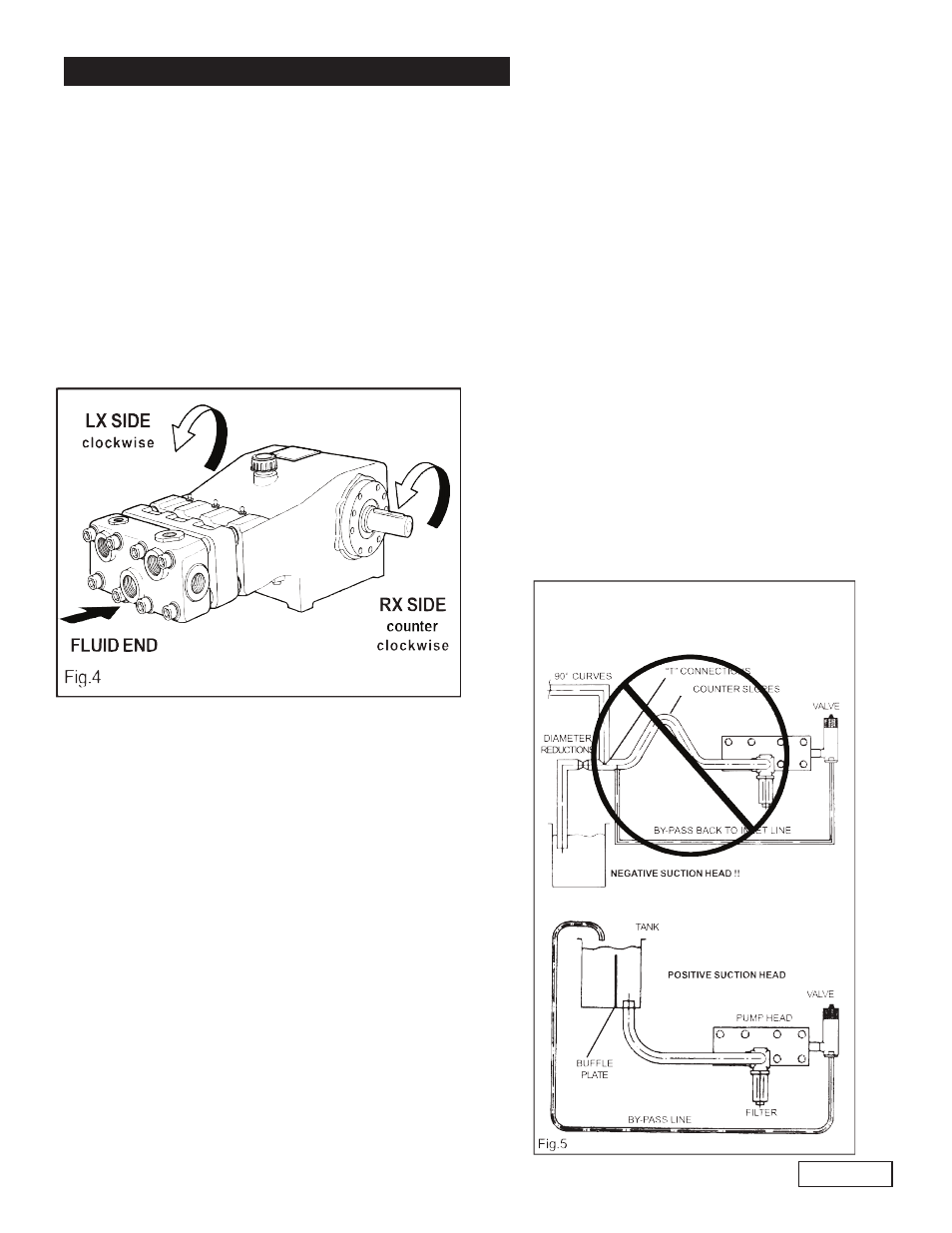

9.2 Direction of rotation

Fig. 4 shows the correct direction of rotation looking at the

pump from the fluid end side. Two arrows stamped on the

crankcase nearby the crankshaft provide the information

as well.

6. Do not use high pressure flexible hoses for the

suction line.

7. Do not use high pressure hydraulic fittings like 90o

elbows, high pressure adapters, high pressure 3 or

4 way nipples and so on.

8. Do not install any kind of detergent injector along the

suction line.

9. Do not install standing valves, check valves or other

kind of one-way valves.

10. Make sure that the feed tank capacity and the water

minimum level do not give rise to turbulence at the

tank outlet port, which, in turn, might create

cavitation at the pump.

11. Do not connect the by-pass line from the valve directly

to the pump suction line.

12. The water flow from the valve should be directed back

in the tank. Make sure that the by-pass and tank

feeding flows to not give rise to turbulence at the

tank outlet port, which, in turn, might create

cavitation at the pump. Proper baffle plates should

be provided inside the tank.

13. Before connecting the suction line to the pump inlet

port make sure the pipe is perfectly clean inside.

9.3 Water connections

In order to isolate the high pressure equipment from the

pump vibrations it is suggested, where applicable, to use

flexible hoses for both suction and delivery lines at least

for the first length. The flexible suction hose must be

rigid enough to prevent it from collapsing during the

suction stroke, when a partial vacuum may occur.

9.4 Suction line

Plunger pumps are not self priming therefore a positive

suction head should always be provided. Information for

the correct suction line:

1. Internal diameter should be at least 3”, in any

point, possibly larger depending on the drop in

pressure due to the length and shape of the line.

2. Should be as straight as possible minimizing changes

in size and direction and positioned in such a way

to allow air pockets and bubbles to escape.

3. Should be perfectly airtight.

4. Should be completely free from 90o elbows, diameter

reductions, counter slopes, “T” connections and

should not be connected to other pipelines.

5. Should be positioned in such a way to prevent the

pipe emptying after the pump stops.