He series, General pump – General Pump HE User Manual

Page 11

GENERAL PUMP

A member of the Interpump Group

HE SERIES

Page 11

11.3 Pumping unit maintenance

The only maintenance operation required for the pumping

unit is greasing the pressure packings through the proper

greasers (1, Fig. 11) located on the packing supports.

Greasing should be carried out at even intervals at

least every 100 hours by means of a hand pump. Stop

greasing when the pump trigger becomes harder to

operate: that means the grease chamber is full. Use top

quality silicone grease (i.e DANKELL OCILUS 250,

penetration coefficient 290 or a corresponding one).

Periodically check the amount of water drained out by the

pump through the hole provided in the lower cover

(Fig. 6). It clearly shows the pressure packing state of

wear; replace them if water dripping becomes continuous

and not intermittent.

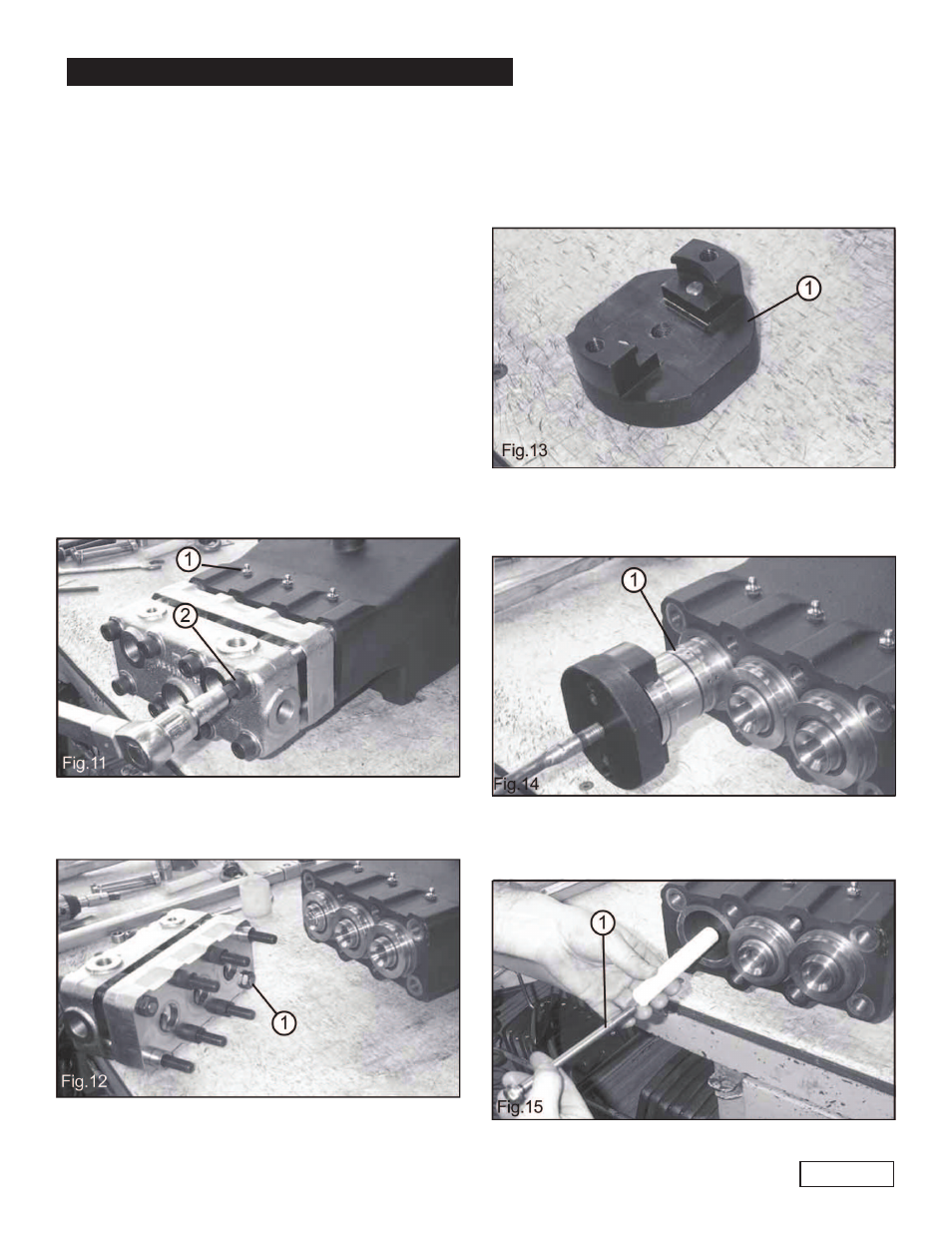

In order to replace the pressure packings, remove the

fluid end first. It is recommended to remove head and

collector from the pump in one piece in order to avoid

possible splitting hazards of the suction/delivery valves

positioned in between. In order to do so loosen and

remove only two of the head bolts (2, Fig. 11).

Replace them with two screws with nut (1, Fig. 12) to keep

head and collector packed together and then

remove the other six head bolts.

Now head and collector can be easily separated from

the pump.

Check the plungers for wear and replace if necessary by

loosening the plunger bolt (1, Fig. 15).

Fit the extractor in place and remove the cylinders

(1, Fig 14).

Once the fluid end is removed, cylinder and packing

supports are free to slide out. Removing the cylinders is

easier by using our extractor pn/ F20000020 or an

equivalent tool.