He series, General pump – General Pump HE User Manual

Page 10

GENERAL PUMP

A member of the Interpump Group

HE SERIES

11. MAINTENANCE INSTRUCTIONS

11.1 Crank mechanism maintenance.

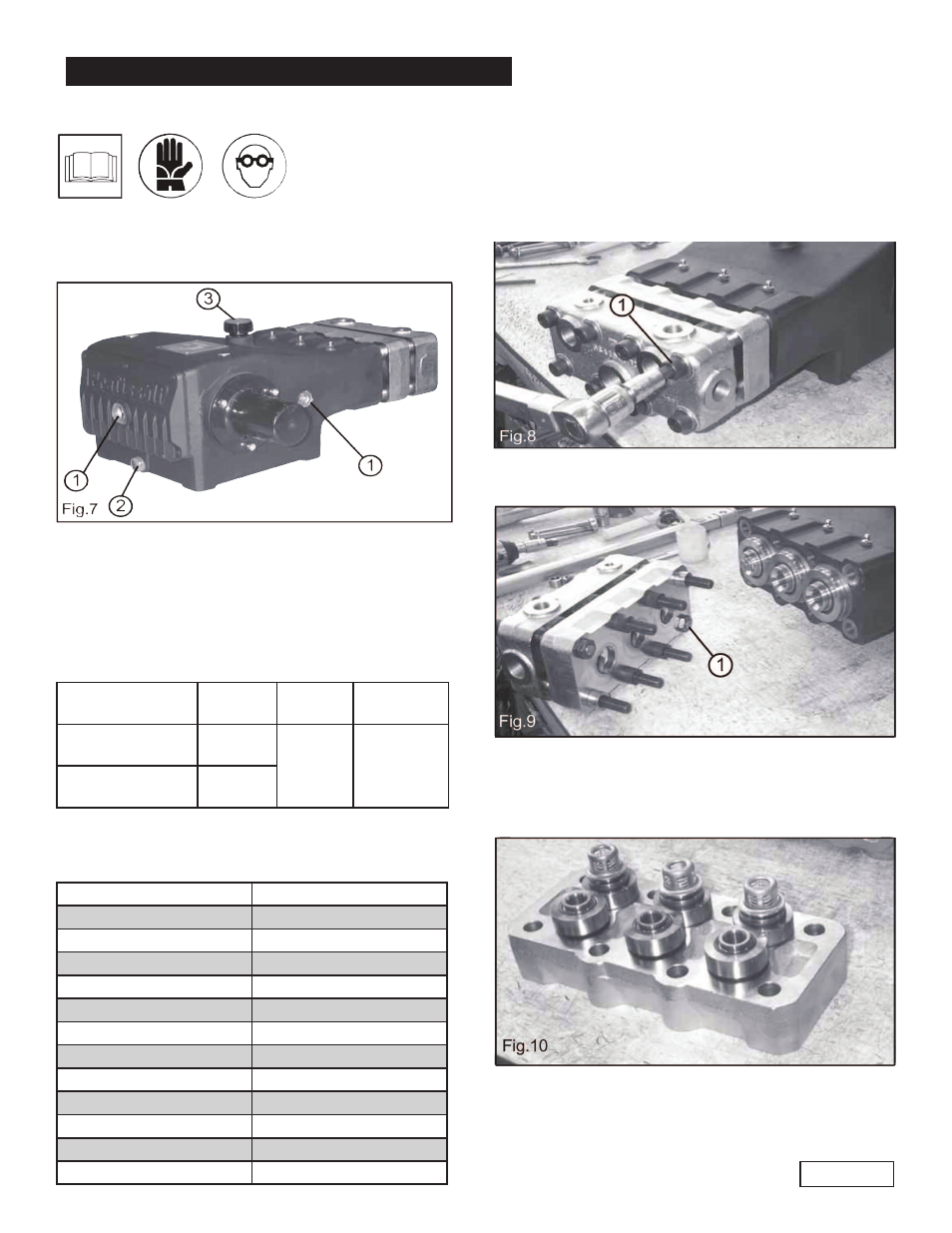

Check oil level through the oil level indicator 1, Fig 7 at

least on a weekly basis.

If necessary, top off oil level from the oil plug 3, Fig. 7

Check the oil when cold and change the oil when still

hot (pump still at working temperature.).

In order to drain the oil from the pump remove the

magnetic plug 2, Fig. 7.

At every oil change clean the magnetic plug 2, Fig. 7 and

check the lower cover of Fig. 6 for grease

sediments or deposits.

OIL CHANGES

Hours

Qty.

Oil

Type

First Change

50

3.1

quarts

ISO

220

Subsequent

Changes

500

BRAND

TYPE

AGIP

ACER 220

ARAL

MOTANOL HP 220

AVIA

AVILUB RSL 220

BP

ENERGOL HL 220

CASTROL

ALPHA ZN 220

ESSO

NUTO 220

FINA

SOLNA 220

IP

HYDRUS 220

MOBIL

DTE OIL BB

SHELL

TELLUS C 220

TEXACO

REGOL OIL 220

TOTAL

CORTIS 220

Oil should be changed at least once a year.

Recommended oils:

11.2 Fluid end maintenance

The fluid end does not require periodical maintenance.

Service operations are limited to valve inspection

and/or replacement, when necessary. It is recommended

to remove head and collector from the pump in one piece

in order to avoid possible splitting hazards of the suction/

delivery valves positioned in between.

In order to do so loosen and remove only two of the

head bolts, 1 Fig. 8.

Replace them with two screws with nut (1, Fig. 9) to keep

head and collector packed up together and then remove

the other six head bolts. Now head and collector can be

easily separated from the pump and disassembled on

work bench (Fig 10).

Check the valve poppets, seats and springs for wear and

replace if necessary. Replace all o-rings at every

inspection. Head bolts should be tightened in a uniform

and alternate way using a torque wrench set for 144 ft.

lbs.

Page 10