Finish Thompson UC (S/N 125040 and lower) User Manual

Page 17

17

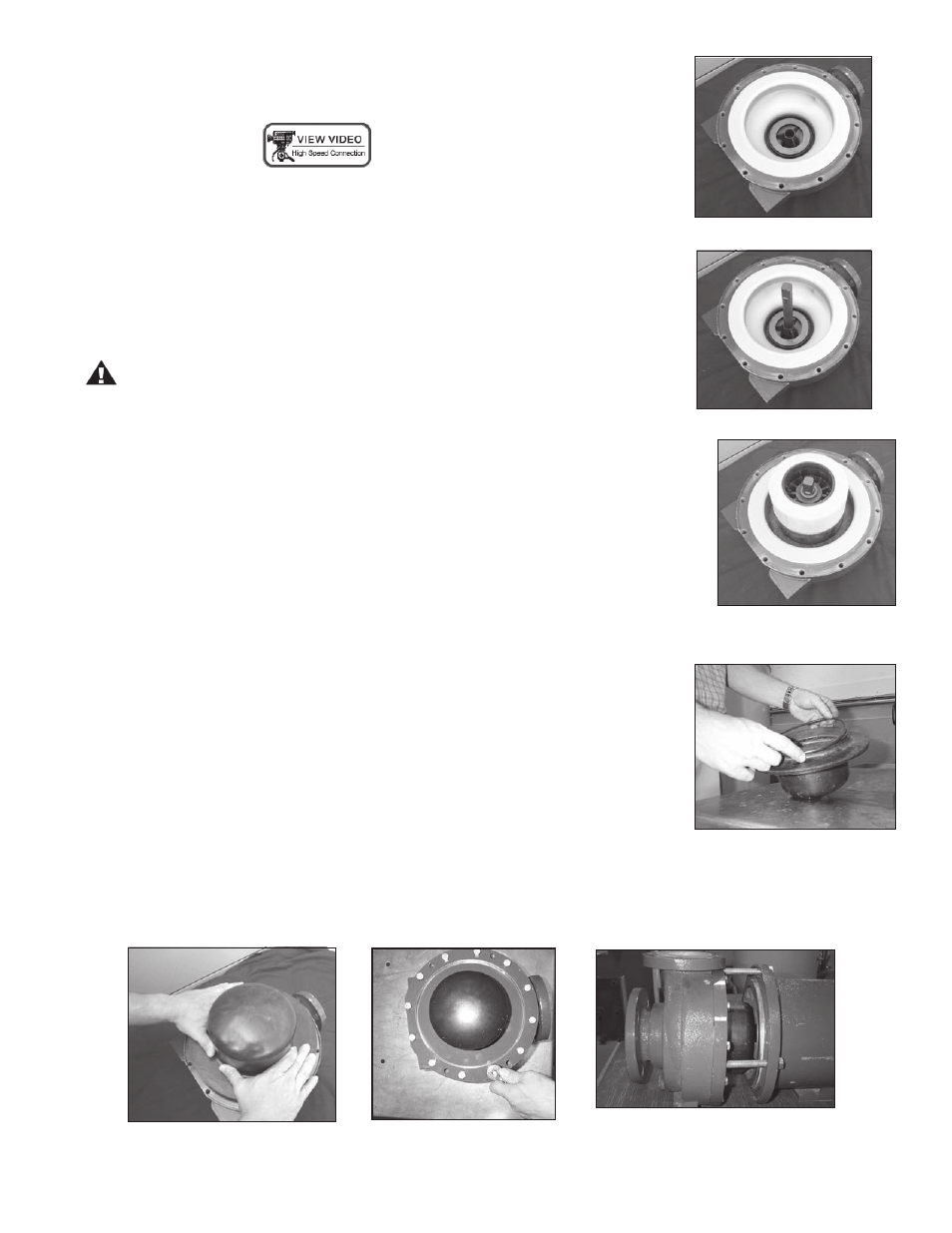

4. Install a new o-ring (item 12) in the barrier assembly’s (item 6) o-ring groove. Lubricate

the o-ring with a suitable lubricant (see figure 26).

5. Slide the barrier assembly over the shaft and impeller assembly. Align the square hole in

the barrier assembly with the square end of the shaft. Press down on the barrier assem-

bly until it is fully seated (see figure 27).

6. Place the rounded edge of the clamp ring (item 7) over the barrier assembly and position

on the rear face of the casing. Make sure to align the flat on the bottom of the clamp ring

with the flat on the bottom of the casing. Attach the clamp ring with (12) 3/8” socket

head cap screws (item 13). Tighten evenly around circumference. Torque the screws to

35 ft-lbs (47 N-m) unlubricated (see figure 28).

7. Using a 3/4” socket, turn the (3) jackscrews (item 14) clockwise until the heads touch

the motor adapter (item 9).

8. Carefully slide the wet end towards the motor adapter until it touches the jackscrews

(there will be some magnetic attraction). See figure 29.

9. Slowly and evenly turn the jackscrews counterclockwise to allow the wet end to

slowly slide into the motor adapter. When the jackscrews are fully retracted, lift the

wet end slightly and slide it onto the motor adapter’s locating flange.

10. Bolt the wet end to the motor adapter by re-installing the (4) 1/2” hex head cap screws (item 15) and torque evenly

to 75 ft-lbs (102 N-m).

figure 25

figure 26

figure 27

figure 28

figure 29

Power End Reassembly

See section Assembly of Pumps without Motors, steps 1-7:

Pump End Reassembly

1. Take the pump casing (item 1) and lay it suction side down on a clean flat sur-

face (see figure 23).

2. Insert the shaft’s (item 5) rounded end into the round hole in the shaft support

(item 2) in the casing (see figure 24).

3. Carefully place the impeller and impeller drive assembly (items 3A, 3,4,4A, 4B,

4C) on the pump shaft (see figure 25). Slowly rotate the impeller assembly and

impeller drive assembly to ensure that there is no binding or dragging.

CAUTION: Do not use steel/iron tools near the magnets. These tools are attracted

to the strong magnetic force and could damage them upon impact.

figure 23

figure 24