Finish Thompson MSKC series User Manual

Page 3

3

BUSHiNG rePLACeMeNT

1. To remove the bushing in the second stage, insert 1/16” pin

punch into balance hole (inner circle of 4 holes) of impeller

drive. Gently tap the bushing out of the back of the impeller

drive. The punch may need to be moved to a different hole if

the bushing is difficult to remove.

2. To replace the bushing, clean the impeller bore. insert the new

bushing into the back of the impeller drive by aligning the

bushing with the impeller bore. Press gently until the bushing

bottoms out (use a block of wood and mallet if necessary).

3. if the bushing in the impeller drive shaft is worn and needs

to be replaced, the complete impeller drive shaft with bush-

ing (item 3) will need to be purchased. Grasp the impeller

assembly in one hand and pull the impeller drive shaft from it.

reASSeMBLY

if the drive magnet assembly (item 10) is to be replaced, install as

follows. On a 56C motor frame, slide the drive magnet assembly

(item 10) onto the motor shaft until it is between 3.110” and

3.120” as measured from the motor face to the top of the magnet

assembly. See figure 1. Align cone point set screw (item 10B)

with key slot on the motor shaft and tighten both set screws with

a 5/32” Allen wrench to 140 in-lbs. (15.8 N-m).

.020” min.

.415” max.

Figure 5

SUCTiON LiFT SYSTeM

1. Prime the system by filling the priming chamber and/or suc-

tion line with a liquid. Allow time for trapped air to work its

way out.

2. if priming via filling the suction line, close the discharge valve

prior to returning the suction line to the tank.

MAiNTeNANCe

DiSASSeMBLY

1. Disconnect power. remove electrical wiring and motor

mounting bolts.

2. Close suction and discharge valves. Disconnect piping.

3. Securely hold or clamp motor in place.

4. For 71/80 motor frame pump, skip to step 5. For 56C motor

frame pumps, remove the four motor adapter bolts (item 14A)

and pull the pump end away from the motor/drive magnet

assembly. Set pump end on motor adapter flange with suc-

tion facing up.

5. remove the six screws (item 12A) from the impeller housing.

6. Using a thin bladed screwdriver, gently separate the first

stage housing (item 1) from the diffuser (item 5). remove

the first stage impeller housing (item 1) being careful to pull

straight off so as not to damage the ceramic front spindle

support. remove the housing o-ring (item 4). Holding down

on the outside of the diffuser assembly (item 5) with one

hand, gently pull the first stage impeller/impeller drive shaft

assembly (items 2 and 3) from the pump.

7. remove the diffuser assembly (item 5) and the diffuser o-ring

(item 6) from the top of the second stage impeller housing

(item 7). remove the second stage impeller housing, the

housing o-ring, the second stage impeller assembly (items

2 & 8), and the barrier (item 9) from the motor adapter (item

11).

8. if the drive magnet assembly (item 10) or the motor needs to

be replaced, do the following. On 56C frame motors, loosen

the two drive magnet set screws (items 10A and 10B) with a

5/32” hex wrench, and remove the drive magnet assembly.

On 71/80 frame motors, insert a 5/32” hex wrench into the

access hole on the top of the motor adapter (item 11) and

loosen the two set screws. remove the drive magnet as-

sembly from the motor shaft. remove the motor adapter if

the motor is being replaced.

FLUSH SYSTeMS

Caution: Some liquids react with water.

1. Completely close suction and discharge valves.

2. Connect water supply to water inlet valve.

3. Connect drain hose to water valve.

4. Open inlet and outlet valves. Flush system until pump is clean

(approximately 5 minutes).

Caution:

Keep the drive magnet and impeller assemblies away from

metal chips or particles.

exAMiNATiON

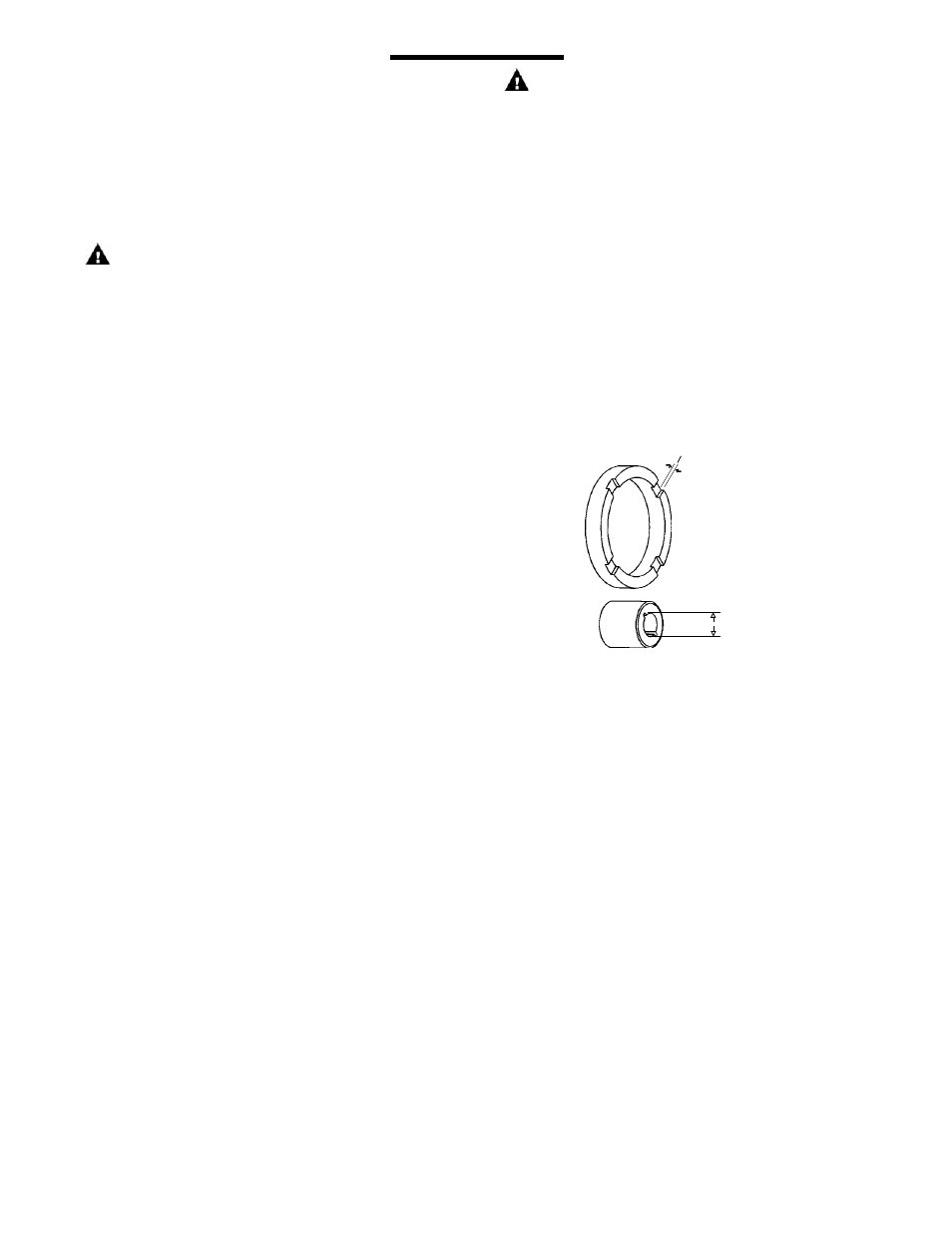

1. Check impeller bushings (item 8A) in both the impeller as-

sembly (item 8) and the impeller drive shaft (item 3), check

both thrust rings (item 2A), both ceramic housing rings, and

both the barrier ceramic post and the first stage impeller

housing ceramic post for cracks, chips, scoring or excess

wear. See figure 5. replace as required.

2. Check for loose magnets on drive magnet assembly or rubbed

areas on the impeller or barrier assemblies. Contact your

distributor or FTi Technical Service if a problem is found.

3. if you do not remove the drive magnet assembly, check the

set screws for tightness before reassembly.