Finish Thompson MSKC series User Manual

Page 2

2

5. Place wet end assembly (comprised of items 1-9) into the

motor adapter (item 11). Grasping the barrier at opposite

bolt tabs, carefully lower the wet end assembly into the mo-

tor adapter/drive assembly. Line up the tabs of the wet end

between the tabs on the motor adapter to avoid pinching

fingers. Once seated, rotate the wet end until bolt holes line

up.

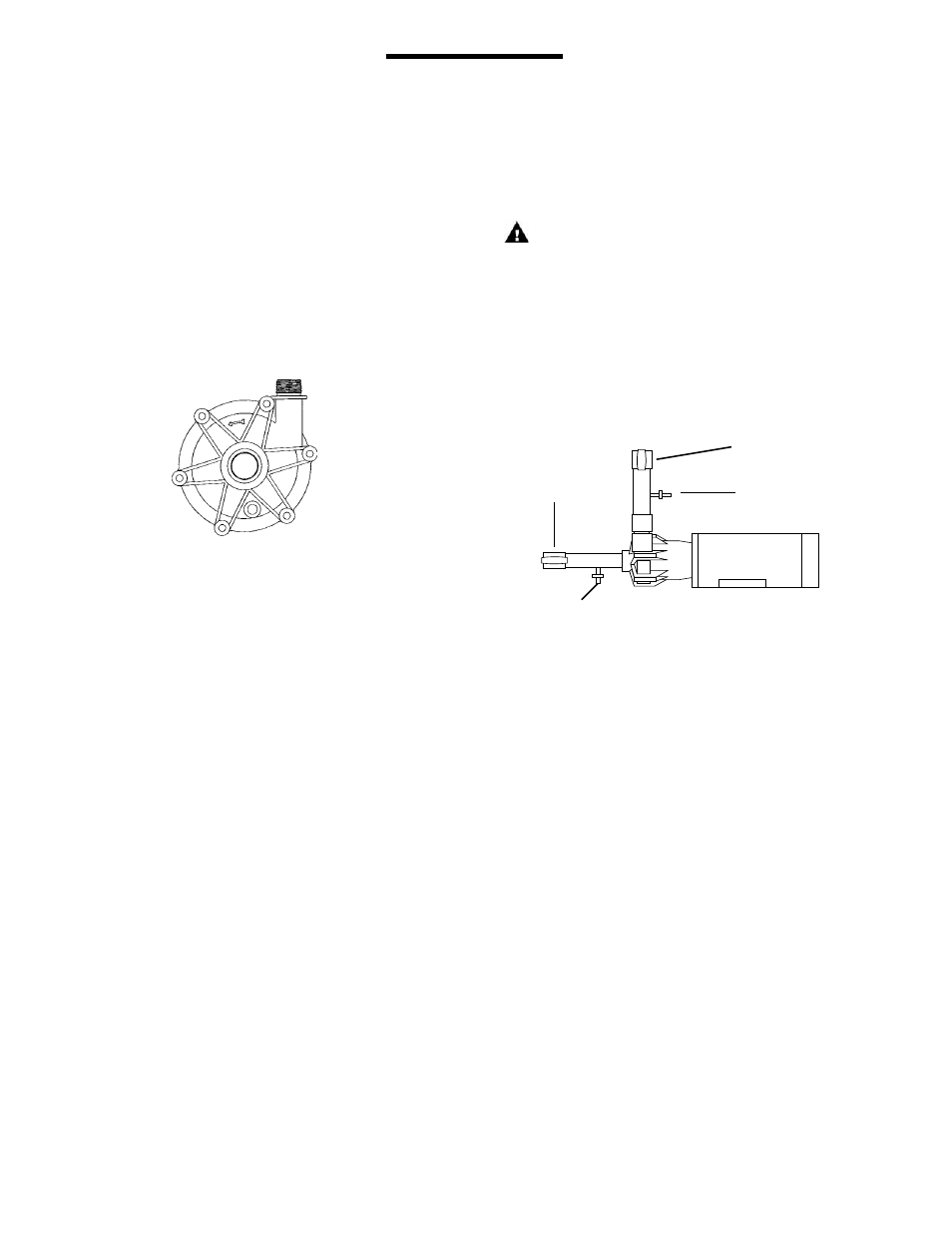

6. Align mounting holes and install 6 mounting screws and

washers (items 12A, 12B & 12C) from hardware package.

Hand tighten screws using pattern shown in Figure 3.

7. rotate motor fan to verify there is no internal binding or rub-

bing.

8. install pump into the system according to installation instruc-

tions.

iNSTALLATiON

MOUNTiNG

Motor should be securely fastened.

PiPiNG

1. Support piping near the pump to eliminate any strain on the

pump casings.

2. Do not overtighten the piping on the discharge on initial

installation. Damage to the discharge can occur. An o-ring

can be used when there is wear and the plastic threads are

loose.

Note: BSP housings are shipped with an o-ring on the dis-

charge.

3. To minimize head loss from friction:

a. increase pipe size by 1 diameter.

b. Use minimal number of pipe bends.

4. Keep bends and valves a minimum of 10 pipe diameters from

the suction and discharge.

5. Position pump as close to the liquid source as possible.

6. Maintain a flooded suction (liquid above pump prior to being

primed).

7. ensure that the piping does not leak and suction is not prone

to clogging.

8. if flexible hose is preferred, use a reinforced hose rated for the

proper temperature and pressure. This helps avoid collapse

or kinks.

eLeCTriCAL

install motor according to NeC requirements and local electrical

codes. Motor should have an overload protection circuit.

iMPoRtant: To verify correct motor rotation:

1. install pump into system.

2. Fully open suction and discharge valves.

3. Allow fluid to flow into the pump. Do not allow pump to run

dry (PTFe and ceramic bushings cannot be run dry without

damage to pump components).

4. Jog motor (allow it to run for one or two seconds) and observe

rotation of motor fan. Correct rotation is clockwise as viewed

from motor fan. refer to directional arrow on pump.

note: A pump running backwards will pump but at a greatly

reduced flow and pressure.

OPerATiON

FLOODeD SUCTiON SYSTeM

1. Completely open suction and discharge valves

2. Start the pump and check liquid flow. if there is no flow, see

the Troubleshooting section.

3. Adjust the flow rate and pressure by regulating the discharge

valve. Do not attempt to adjust the flow with the suction valve.

6

1

2

3

4

5

Figure 3

Suction

Valve

Water

Outlet

Valve

Discharge Valve

Water Inlet Valve

Figure 4

9. install valves on suction and discharge lines (a minimum of

10 pipe diameters from the pump).

10. For units in a suction lift system, install appropriate piping in

the discharge to allow priming of the pump.

note: This pump is not self-priming.

11. The suction valve should be completely open to avoid

restricting suction flow.

Caution:

To stop the pump if prime is lost, use one of the following:

(1) pressure switch on the discharge, (2) vacuum switch on

the suction, (3) a power monitor to monitor motor power.

12. When pumping liquids that may solidify or crystallize, a flush

system should be added to the piping. See Figure 4. install

water inlet and outlet valves as shown.

note: This pump is provided with a provision for a customer

installed 1/4” NPT drain in the impeller housing. See Drain

installation Section for details.