Sp22 assembly, installation and operation – Finish Thompson SP22 Series Self-Priming User Manual

Page 6

6

SP22 Assembly, Installation and Operation

Unpacking and Inspection

Unpack the pump and examine for any signs of shipping damage

If damage is detected, save the packaging and notify the carrier

immediately

Section I - Assembly

Tools Required:

3/8” Allen wrench or ballpoint hex socket, 3/16” Allen wrench,

10 mm hex socket, metric socket set (for pumps with IEC outer

drives)

Pumps with Motors

Proceed to “Installation” Section

Pumps Without Motors

NOTE: All motors must have motor feet

1 Remove the pump, drive magnet assembly and hardware

package from the carton

CAUTION: Keep away from metallic particles, tools and

electronics Drive magnets MUST be free of metal chips

WARNING: Keep the drive magnet away from the open end

of the motor adapter and barrier Strong magnetic attraction

could allow the drive hub to enter the motor adapter result-

ing in injury or damage

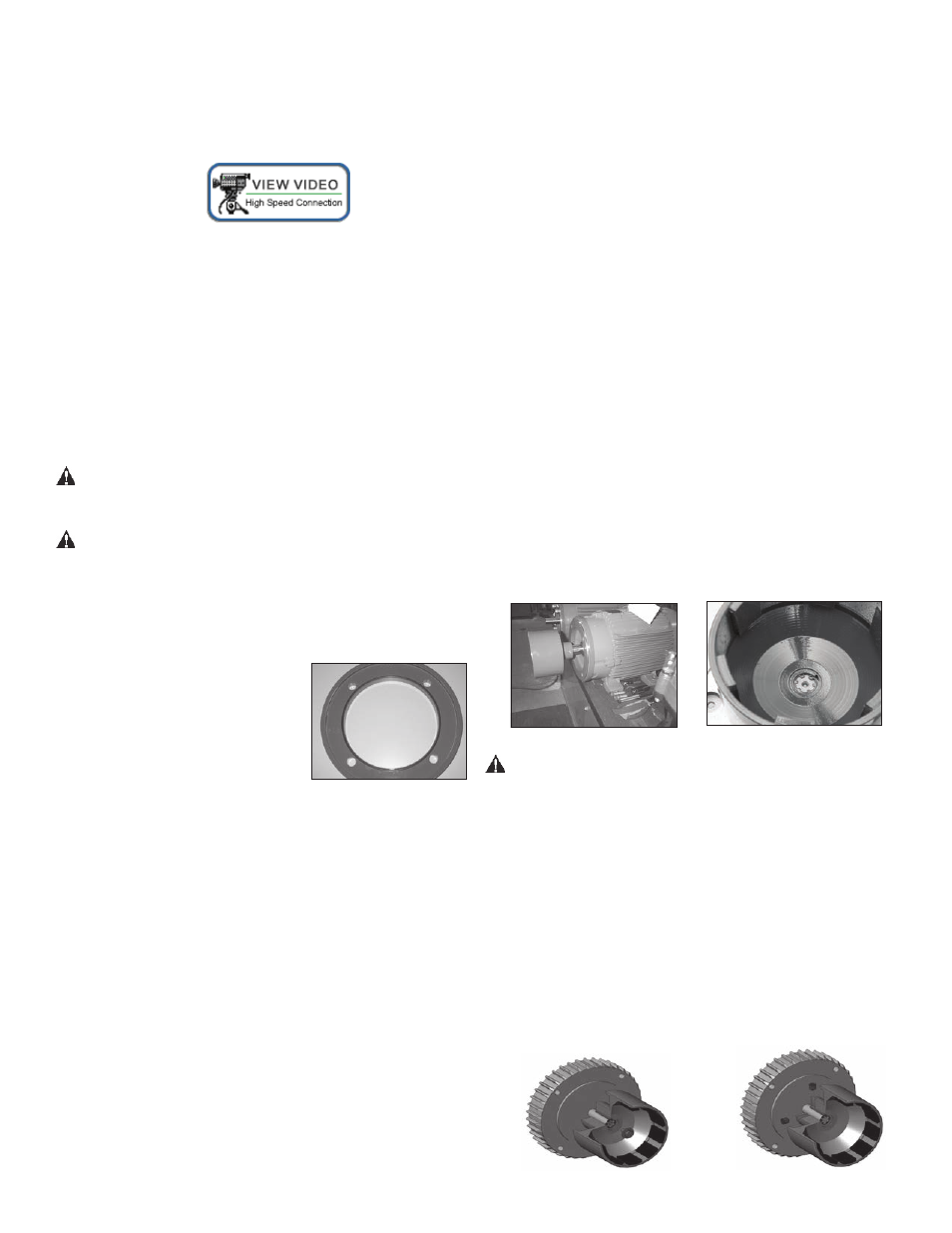

2. For 184TC motors, proceed to step 3

For 213/215 NEMA motors only

– Install the o-ring (item 14A) in

the groove in the motor adapter

Use small amount of petroleum

jelly (or silicone grease on EPDM

o-rings) to help hold the o-ring in

place Install the larger female

rabbet portion of the motor adapter flange (item 14) on the

motor face Align the holes in the adapter with the holes in

the motor face See figure 1

For IEC 90, 100/112, 132 with B5 flange motors - Install

flange (item 14) on motor with pockets (depressions) side

towards the motor face Align (4) holes in the adapter with

the holes in the motor face install the (4) customer supplied

bolts, lock washers and flat washers through the motor

adapter into the motor face See figure 1

Flange hole thread size:

90 B5 = M10 x 1 5

100/112 B5 = M12 x 1 75

132 B5 = M12 x 1 75

For 90 & 132 with B14 flange & 145TC motors - Install

the flange item 14) on motor with pockets (depressions) side

towards the motor face Align (4) holes in the adapter with

the holes in the motor face Install (4) bolts, lock washers

and flat washers (items 24, 25, 26) through the motor

adapter into the motor face See figure 1

For 100/112 with B14 flange motors

Install flange (item 10) on motor with pockets (depressions)

towards the pump motor adapter (item 8) Align (4) holes in

the adapter with the holes in the motor face Install (4) bolts,

lock washers and flat washers (items 20, 21, 22) through

the motor adapter into the motor face

Torque bolts to the following:

90/100/112 B14 frame (M8) = 130 in-lb (14 7 N-m)

132 B14 (M10) frame (M10) = 240 in-lb (27 1 N-m)

90 frame B5 (M10) = 240 in-lb (27 1 N-m)

100/112/132 B5 (M12) = 480 in-lb (54 3 N-m)

3 Coat the motor shaft with anti-seize compound Insert key

supplied with motor into keyway on motor shaft

NOTE: Make sure the motor shaft is clean and free of burrs

The outer drive is precision machined and has a bore toler-

ance of + 0005/-0 inch

4 Slide the outer drive magnet assembly (item 13) onto the

motor shaft until the motor shaft contacts the snap ring in

the bore of the drive Figures 2 and 3

Figure 2

Figure 3

WARNING: Be careful, magnets will try to attract tools

Metric Motors: Secure the drive to the motor shaft using

bolt, lock washer and flat washer (items 21, 22, 23) Thread

the bolt into the end of the motor shaft (while holding the

outer drive to prevent it from turning) See figure 4

Tighten the bolt to the following:

· 90 frame (M8)

= 130 in-lb (14 7 N-m)

· 100/112 frame (M10) = 240 in-lb (27 1 N-m)

· 132 frame (M12) = 480 in-lb (54 3 N-m)

NEMA Motors: Install set screws (item 13B) into threaded

holes on the side of the outer drive magnet assembly Using

a 3/16” Allen wrench, tighten to 228 in-lbs (25 8 N-m) See

figure 5

Figure 4

Figure 5

Figure 1