Finish Thompson SP22 Series Self-Priming User Manual

Page 10

10

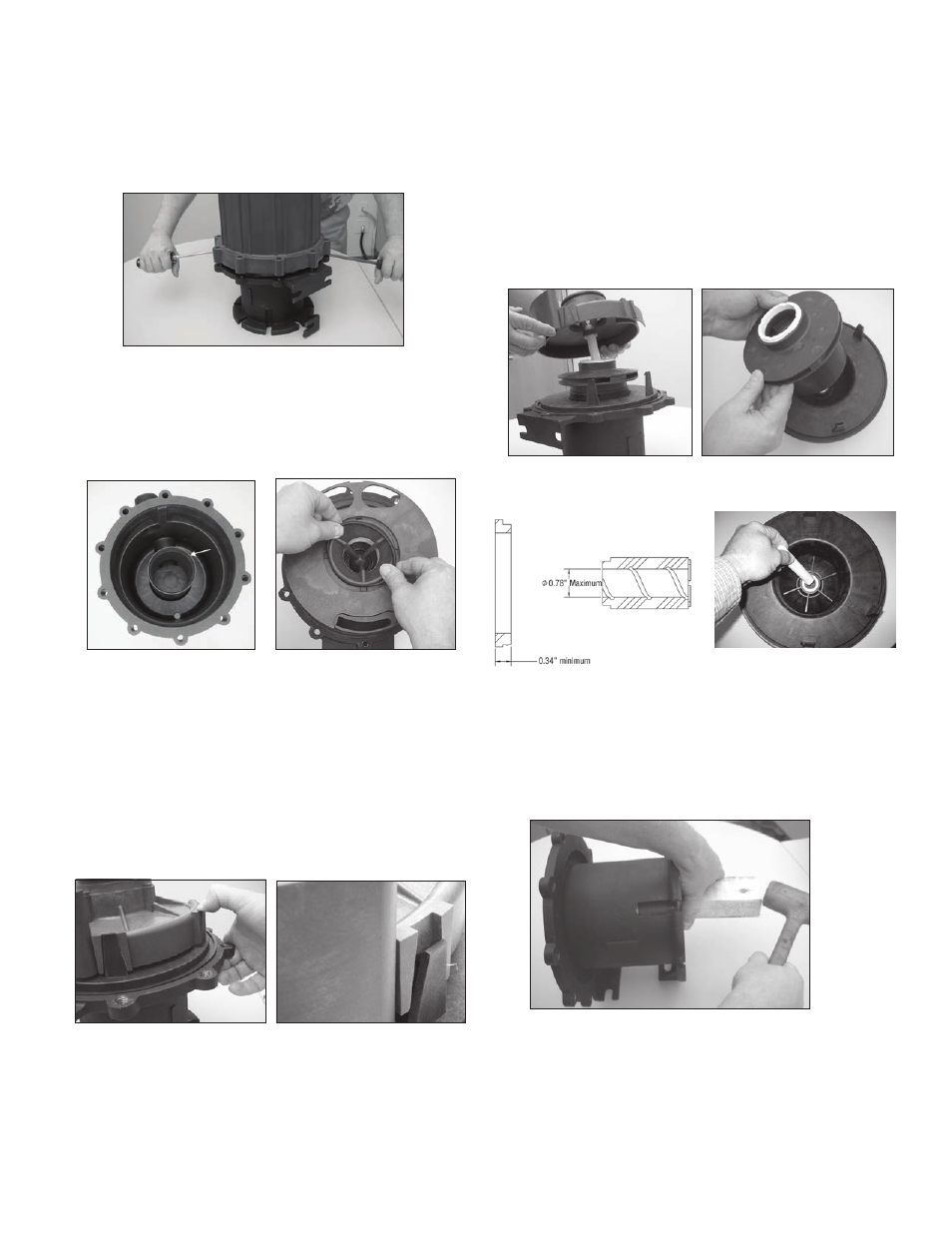

Applying equal pressure, gently pry both screwdrivers in

upward motion away from the table (to avoid damaging

sealing surface) See figure 12A Housing is tight due to o-

ring seal on the internal “gooseneck”

NOTE: Do not twist the screwdrivers or damage may occur

to the housing

5 Examine the housing for signs of wear or damage Inspect

the gooseneck and suction and discharge for cracks See

figure 13 Inspect fill and drain plug o-rings (item 2A) for

chemical attack, swelling, brittleness, cuts, etc

Figure 12A

Figure 13

6 Carefully remove the inner volute o-ring (item 4) See figure

14 Inspect for chemical attack, swelling, brittleness, cuts, etc

7 Pull the separator plate (item 5) off the inner volute (item 6)

Inspect for damage and cracks

8 To remove the inner volute (item 6), pull back on the (3) snap

fit prongs one at a time so that the hook portion falls into the

channel on the inner volute See figures 15 and 16

Figure 14

Figure 15

Figure 16

9 Pull the inner volute straight off Be careful since the impeller

shaft may come out with the inner volute See figure 17

10 Remove impeller/inner drive assembly (items 7A, 7, 8, 8A)

Inspect for signs of rubbing, damage and wear See figure

18 Check the impeller thrust ring and bushing for wear See

figure 19

11 Remove the impeller shaft (item 9) from the barrier and

check for signs of cracking, chipping, scoring or wear See

figure 20

Figure 17

Figure 18

Figure 19

Figure 20

12 Remove the barrier (item 11) from the motor adapter (item

12) (make sure the impeller shaft has been removed) If nec-

essary, gently tap on the backside of the barrier with a soft

rod (wood, plastic, etc) Inspect the inside and outside of the

barrier for signs of rubbing See figure 21

Figure 21