Finish Thompson SP22 Series Self-Priming User Manual

Page 4

4

CAUTION: Never start or operate with a closed suction valve

WARNING: Operation without priming or against a closed discharge valve can result in high temperatures that can result in

injury or damage to pump components

CAUTION: Always provide adequate NPSHa (net positive suction head available) It is recommended to provide at least 2 feet

(61 cm) above the NPSHr (net positive suction head required)

CAUTION: If pump is used on variable speed drive, do not exceed the frequency for which the pump was designed (for example,

if the pump is a 50 Hz model, do not exceed 50 Hz)

SP22 Capabilities

• Maximum Working Pressure: 90 psi (6 2 bar)

• Maximum Temperature:

Polypropylene -180º F (82º C); PVDF – 220º F (104º C)

NOTE: Maximum temperature is application dependent Consult a chemical resistance guide or the chemical manufacturer for

chemical compatibility and temperature limits

• Maximum Lift: 25 feet (7 6 meters)

NOTE: Lift determined on fresh, cold water with 3” Schedule 40 pipe Specific gravity affects lift capability Divide 25 feet (7 6

meters) by the specific gravity to determine equivalent maximum lift

• Solids: Maximum particle size is 100 microns for slurries and 1/64” ( 4 mm) for occasional solids Maximum hardness is 80 HS

Maximum concentration is 10% by weight

If solids are being pumped, it is recommended that the pump have silicon

carbide components for best results Pumping solids may lead to increased wear

NOTE: While the pump is capable of being used in sump applications, it is NOT a trash pump Care must be taken to ensure that

debris and foreign objects do not enter the pump or damage may result FTI recommends using a 2” (50 8 mm) or 3” (76 2 mm)

strainer basket with 1/8” (3 2 mm) perforations Regular strainer basket maintenance is required to prevent plugging and a

decrease in NPSHa so not to starve and damage the pump

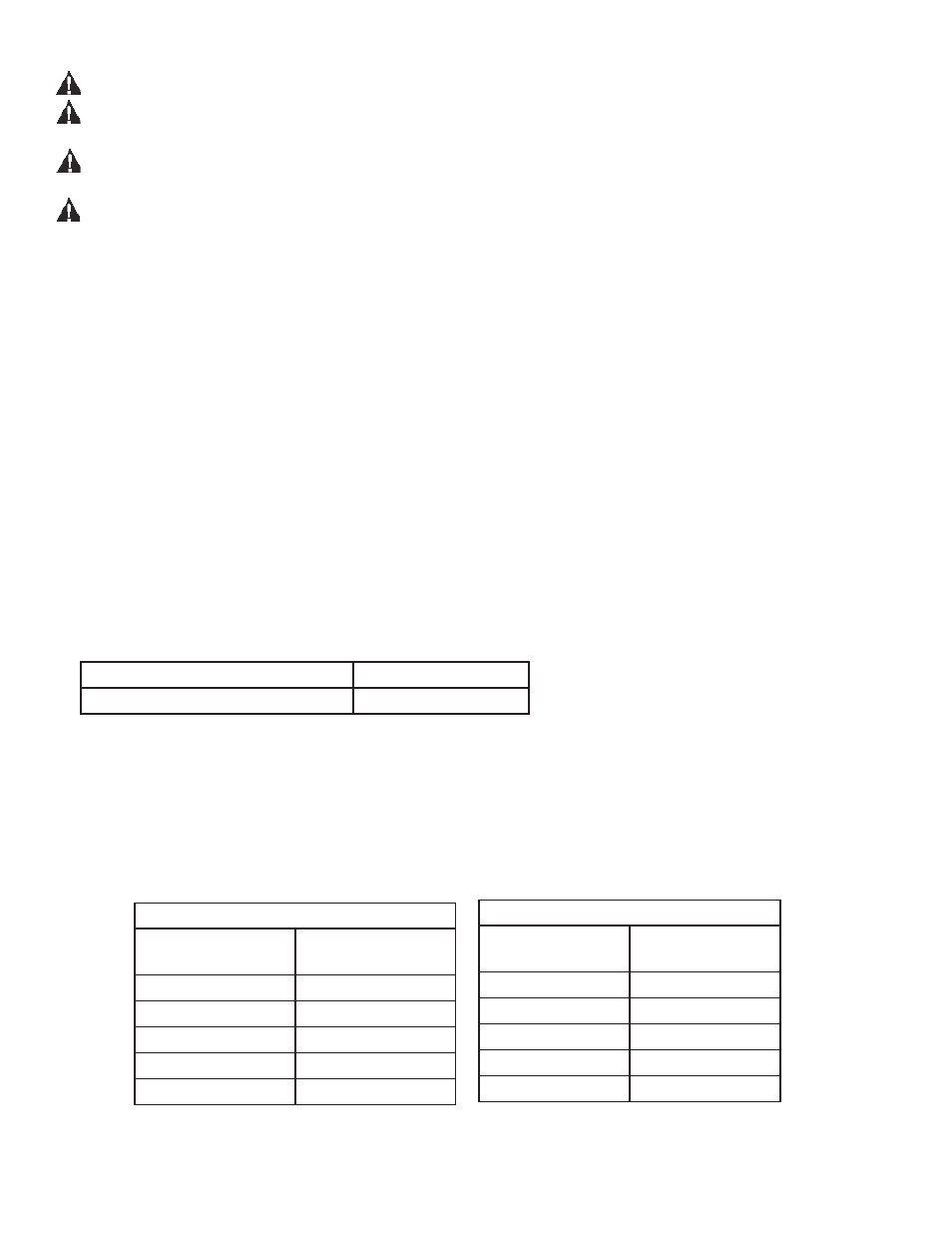

• Minimum Allowable Flow Rate

Do not allow the flow rate to drop below the minimum flow rate in the chart below:

• Maximum Allowable Motor Power

Do not exceed 7 5 kW (10 horsepower) for 50 Hz, 2900 rpm applications For 60 Hz, 3450 rpm applications, the pump is capable

of starting a 15 horsepower motor but is limited to a maximum of 13 horsepower (9 7 kW) while running Use the information in

the chart below to determine the maximum specific gravity capabilities by impeller trim for non-overloading applications The

use of a power monitor is strongly recommended for 60 Hz applications above 10 horsepower (7 5 kW)

•

Maximum Noise Level: 80 dBA (pump only)

• Maximum Specific Gravity for Non-Overloading Applications

3450 rpm (60 Hz)

Impeller

Diameter

Maximum Specific

Gravity

7” (177 8 mm)

1 0

6 5” (165 1 mm)

1 3

6” (152 4 mm)

1 6

5 5” (139 7 mm)

1 8

5” (127 0 mm)

1 8

2900 rpm (50 Hz)

Impeller

Diameter

Maximum Specific

Gravity

177 8 mm (7”)

1 35

165 1 mm (6 5”)

1 65

152 4 mm (6”)

1 8

139 7 mm (5 5”)

1 8

127 0 mm (5”)

1 8

3450/2900 rpm

1750/1450 rpm

10 US gpm (2 3 m

3

/hr)

5 US gpm (1 1

m3

/hr)