Farm Star T55-74 User Manual

Page 19

25

18

I N S T R U C T I O N S

(continued)

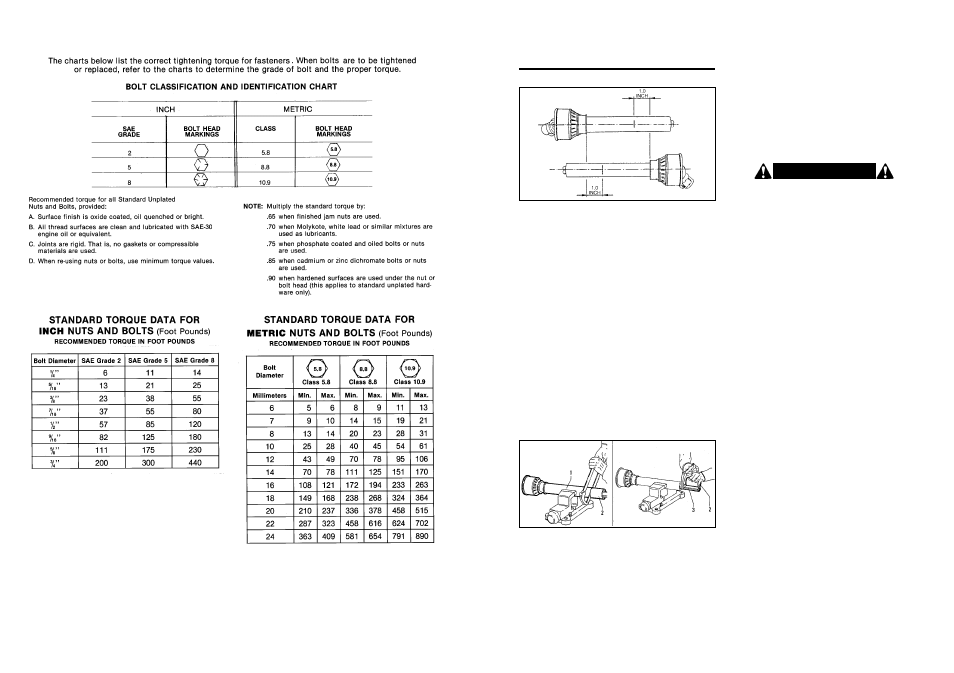

P R O P E R T O R Q U E F O R FA S T E N E R S

A S S E M B LY

(continued)

1. Place the two halves of the driveline together, keeping

them parallel (see Figure 3). Using a felt-tip pen,

matchmark the place where the two halves must be

shortened, measuring 1.0 inch from the beginning of

each half, as shown in Figure 3.

Double check before making any cuts. Cut PTO

drivelines cannot be returned.

Figure 3

Figure 4

2. Raise and lower the mower to determine position with

greatest distance between the PTO shaft and gearbox

input shaft. Shut tractor off, leaving tiller in position of

greatest distance between shafts. SECURELY

BLOCK TILLER IN POSITION.

3. Hold driveline sections parallel to each other and

check for minimum 6” (15cm) overlap. If driveline

has been marked for cutting, overlap will be the

distance between the two marks. If driveline has less

than minimum overlap, do not use. Contact

authorized Worksaver dealer.

5. Repeat the procedure to the other driveline half.

Remove all burrs and cuttings.

6. Apply multi-purpose grease to inside of outer (female)

driveline section. Assemble driveline and install on

tractor and tiller. Pull on each driveline section to be

sure yokes lock into place. Make certain driveline

shielding is in place and in good condition.

4. If driveline must be cut to a shorter length, clamp

driveline in a well padded vise to prevent damage to

the shield. Cut off shield where marked. Using cut-off

section of shield as a guide, cut shaft the same

amount. (Figure 4.)

W A R N I N G !

When attaching PTO yoke to tractor PTO shaft, it is

important that spring-activated locking pin or balls

operate freely and are seated in groove on PTO shaft.

A loose shaft could slip off and result in personal

injury or damage to equipment.

If the PTO driveline assembly contacts the swinging

drawbar, damage will occur to the driveshaft shield and

possibly the driveshaft itself. (NOT covered under

warranty.)

8. Check the swinging drawbar of the tractor and make

sure the PTO driveline assembly will not contact. The

swinging drawbar can be moved forward on some

tractors or it can be removed.

Use the lift control limiting stop on the tractor control

lever to limit the upward travel of the lever so the lift can-

not be raised high enough to cause contact between the

drive shaft shield and front shielding. It is recommended

that the tiller not be raised more than 14 inches off the

ground with the PTO engaged.

NOTE: This type of damage is NOT covered under

warranty, as it is totally under the control and the

responsibility of the operator.

Then raise the tractor lift very slowly, making sure that

the front drive shaft shield does not hit the front of the

tiller. If it does, damage will be done to the drive shaft

shield and, if interference is bad enough, it WILL also

damage the drive shaft itself.

7. Carefully raise and lower the tiller and check to be sure

the PTO assembly does not jam. If it does, cut equal

amounts from each half of the PTO assembly.