2 input signals – FEC AFC1500 User Manual

Page 14

AFC1500 Multi-2 Unit Hardware Manual (Rev. 2)

PAGE 4 - 14

Chapter 4: Installation & Wiring

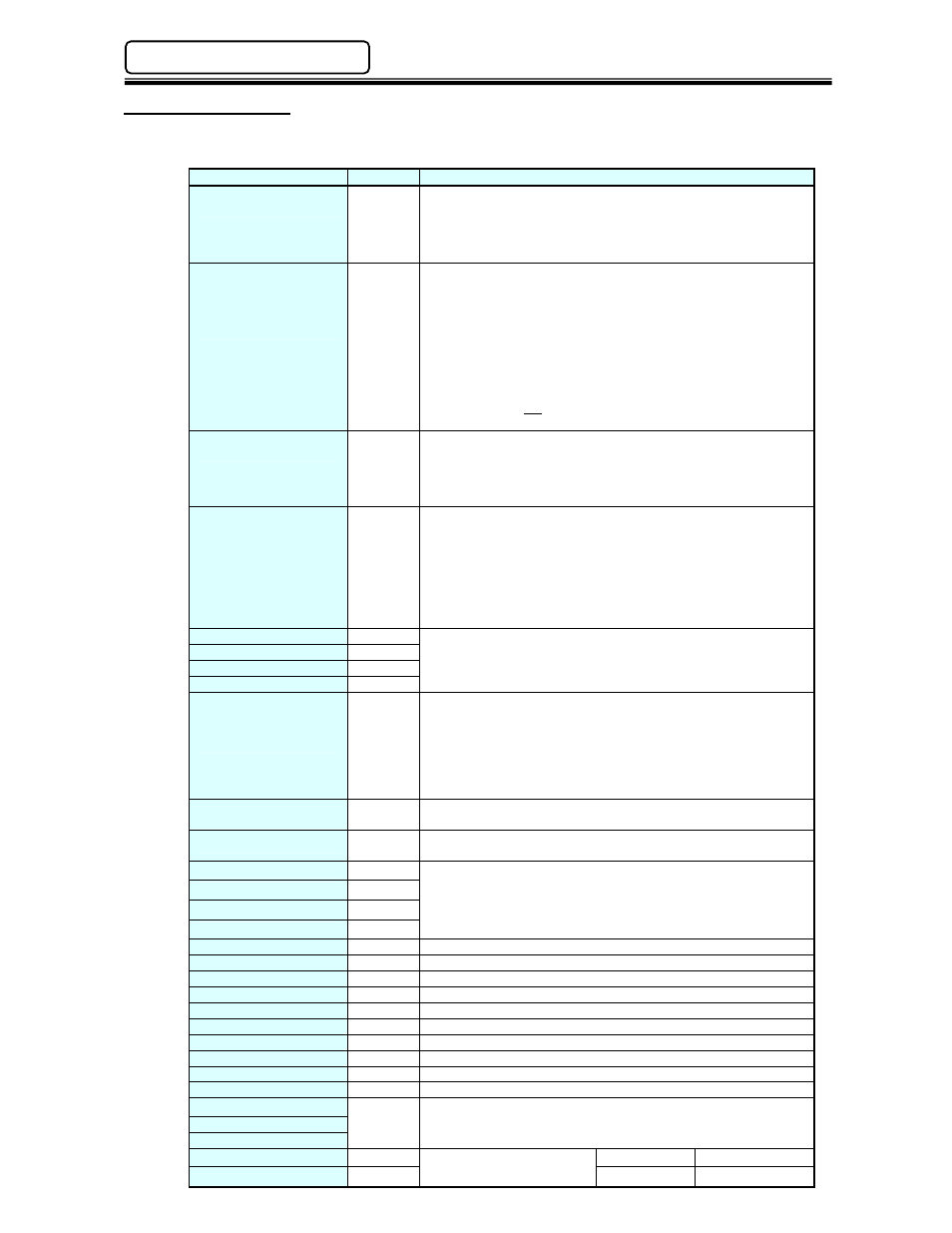

4.7.2 Input Signals

The list below contains a description of the Input signals available on the I/O interface. Further input

mapping can be found in the individual interface information (See Chapter 5).

Signal

Contact

Description

Emergency Stop

N.C.

Emergency Stop Input.

Signal MUST be Active to perform a fastening operation.

When this signal is inactive (off), all Multi-2 Unit operation ceases,

all spindles in motion will stop, and all communication ports &

input/outputs will be disabled.

Reset

N.O.

Reset Input.

When active (on), this signal will clear all spindle data and

discrete outputs. A Zero Check of all torque transducers will be

completed. During the Zero Check, the CHECK lamp will

illuminate, the READY signal will turn OFF, and the ACCEPT or

REJECT lamp will light to indicate the result of the Zero Check. If

the System has been disabled by an Abnormal output, the

System will not return to normal operation until the Abnormal

condition has been corrected, and this signal has been input for

200~500ms. Do not input this signal between cycles as part of an

automatic cycle due to the potential for fastening data loss.

Reverse

N.O.

Reverse Spindle Rotation Input.

All spindles will rotate in an opposite direction (of fastening) for as

long as this signal is activated (on) and maintained. The Reverse

input functions the same as the reverse pushbutton on the front of

the Multi-2 Unit.

Start

N.O.

Start Cycle Input.

The Start input automatically resets the previous cycle, clears all

data to zero, and initiates the next fastening cycle. The start input

requires a pulse of 200~500 milliseconds if the Multi-2 Unit is set

up for AUTOMATIC Start input. If it is set up for DEADMAN

(hand-held operation) input, the Start input must be maintained

"on" for the entire cycle. Typically this signal is held on until

confirmation of the “Busy” signal is received.

Sequence Select 0

N.O.

Sequence Select Input.

These 5 inputs form a binary code which is capable of selecting

up to 16 different operation sequences. Refer to Table 1. (Can be

used for part model selection)

Sequence Select 1

N.O.

Sequence Select 2

N.O.

Sequence Select 3

N.O.

Cycle Count Up

N.O.

Cycle Count Input.

The System cycle counter will increment each time this signal is

input if the CYCLE COUNT UP is set to PLC SIGNAL in the

Multi-2 Unit. The Cycle Count input requires a pulse of 200~500

milliseconds to increment the counter. If the CYCLE COUNT UP

is set to AUTO, the cycle counter increments automatically at the

end of every fastening.

Cycle Count Clear

N.O.

The internal cycle counter is reset when this signal is input.

Resetting the counter value requires a 200~500ms pulse.

Self Check Disable

N.O.

Disables the Calibration & Zero Level check that automatically is

performed at the start of each cycle

INPORT 1

N.O.

External Sequence Input.

These four (4) signals are external inputs to the fastening

sequence. When a [PLC INPUT WAIT] instruction is programmed

in the fastening sequence, it will stop until the designated external

input is active.

INPORT 2

N.O.

INPORT 3

N.O.

INPORT 4

N.O.

BYPASS Spindle No.1

N.O.

Bypass’s spindle #1 - Spindle is ignored as if it does not exist.

BYPASS Spindle No.2

N.O.

Bypass’s spindle #2 - Spindle is ignored as if it does not exist.

BYPASS Spindle No.3

N.O.

Bypass’s spindle #3 - Spindle is ignored as if it does not exist.

BYPASS Spindle No.4

N.O.

Bypass’s spindle #4 - Spindle is ignored as if it does not exist.

BYPASS Spindle No.5

N.O.

Bypass’s spindle #5 - Spindle is ignored as if it does not exist.

BYPASS Spindle No.6

N.O.

Bypass’s spindle #6 - Spindle is ignored as if it does not exist.

BYPASS Spindle No.7

N.O.

Bypass’s spindle #7 - Spindle is ignored as if it does not exist.

BYPASS Spindle No.8

N.O.

Bypass’s spindle #8 - Spindle is ignored as if it does not exist.

BYPASS Spindle No.9

N.O.

Bypass’s spindle #9 - Spindle is ignored as if it does not exist.

BYPASS Spindle No10

N.O.

Bypass’s spindle #10 - Spindle is ignored as if it does not exist.

Data Select 0

These 3 inputs form a binary code to select up to 8 Output Data

Banks. Used for Digital I/O interfaces. NOTE: Not used for

Fieldbus interfaces. [See Table 3 on Page 5-12]

Data Select 1

N.O.

Data Select 2

Input Signal Power

Common for input signal.

Sink Type

+24V

Input Signal Power

Source Type

+0V