SPP Pumps Thrustream User Manual

Page 7

Operators Instructions for Horizontal

Standard Thrustream Centrifugal Pumps

Manual No/Rev

W12-003E / 6

Our policy is one of continuous improvement and we reserve the right to alter specifications at any time

Page 7 of 28

freely by hand by turning the shaft.

If the pump has been in storage, remove any

protective coatings. If the bearing housings

were filled with grease remove the bearing

housings, clean, and re-lubricate the bearings.

4.6

Suction Pipework

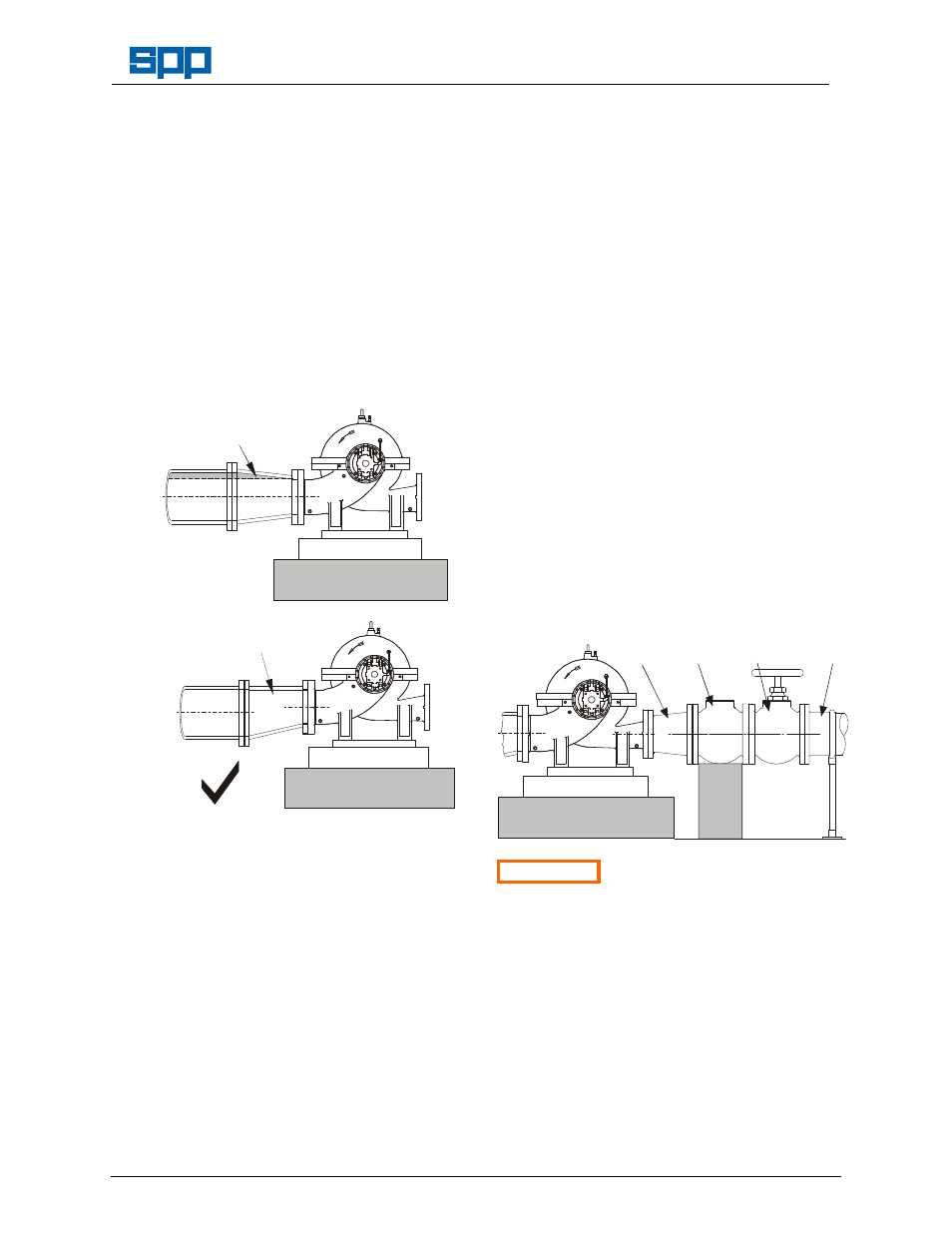

The run of suction pipework must be such that

air can NOT become trapped where it would

be drawn into the pump on starting. The bore

of the suction pipe is recommended to be one

or two sizes larger than the pump suction

branch and reducers if used must be eccentric

to eliminate the possibility of an air pocket

being formed.

CONCENTRIC REDUCER

WILL TRAP AIR IN THE

SUCTION PIPE

Foundation Plinth

X

FLAT TOP REDUCER

WILL NOT TRAP AIR IN

THE SUCTION PIPE

Foundation Plinth

Bends in the suction pipeline should be as

large as possible, the pipe made as short and

as straight as possible and all joints must be

fully airtight. A gradual rise in the suction

pipeline is recommended to prevent formation

of air pockets. If fitting a foot valve, it should

have a free area of one and a half times the

area of the suction pipe.

Where pumping water at temperatures above

70°C, care must be taken to ensure that

enough pressure is available at the impeller

entry to prevent vaporisation. Expansion

joints are recommended to prevent strain on

the pump casing.

An appropriate fine strainer is recommended

to prevent foreign matter from being drawn

into the pump. A screen or basket strainer

may also be required to hold back larger

items. These should be sized to maintain the

flow through them to below 0.6 m/s.

The suction pipe work must be flushed clean

to ensure that site debris is not drawn into the

pump when it is commissioned.

4.7

Discharge Pipework

The bore of the discharge pipe should ideally

be sized to ensure a flow velocity of 2.5 to 3

m/s is not exceeded. This is usually one size

larger than the discharge branch. Pipework

should be as short and straight as possible to

reduce friction head loss.

A non-return valve is usually fitted to prevent

the pump from excessive backpressure and

reverse rotation and a discharge valve is

usually fitted for isolation purposes to allow for

inspection and maintenance on the pump.

Where adverse suction conditions may cause

the pump to lose its prime, the use of an

external automatic priming device, such as a

vacuum pump, is recommended.

The suction and discharge pipework must be

independently supported and positioned such

that no excessive forces and moments are

exerted on the pump flanges.

INCREASER

CHECK

VALVE

DISCHARGE

VALVE

DISCHARGE

PIPE

Foundation Plinth

Check

Valve

Support

ATTENTION Failure to support suction and

delivery pipework may result in distortion of

the pump casing, with the possibility of early

pump failure.

4.8

Guards

If guards have been removed to install packing

or to check mechanical seal connections, they

MUST be replaced to maintain safe operation

of the pump. Refer to the General

Arrangement drawing for specific fixing

methods for the guarding supplied.