SPP Pumps Thrustream User Manual

Page 18

Manual No/Rev

W12-003E / 6

Operators Instructions for Horizontal

Standard Thrustream Centrifugal Pumps

Our policy is one of continuous improvement and we reserve the right to alter specifications at any time

Page 18 of 28

10. Fit washers and nuts (41A & 41F) to retain the

support frames.

11. For soft packed pumps: Fit the packing (51),

lantern rings (46) and glands (50) in position

as per instructions in section 6.2.

12. Fit the mechanical seals to the shaft as per

the manufacturer’s instructions.

13. Fit new oil seals into the support frames (61)

ready for assembly of the bearings and

bearing housings.

14. Heat the non-drive end bearing (66) to

approximately 100

0

C (212

0

F) using bearing

hot-plate, induction heater or oven. NOTE:-

Do not exceed 120

0

C (248

0

F).

15. Slide the heated bearing onto the shaft to abut

the shoulder

16. Place the locking washer (75F) onto the shaft

and screw on the bearing lock nut (75).

17. Fit and tighten the bearing locknut to 300 Nm

and lift the tab of the lock washer.

18. Repeat paragraphs 14 to 16 for the drive end

bearing (67).

19. Cool the bearings to room temperature and

coat both sides with two/three ounces of

recommended grease.

20. Coat the inside of the bearing housings (A62)

with grease and slide into place over each

bearing.

21. Secure the bearing housings (A62 & B62) to

the inserts (41) with four hexagon screws &

washers (61A & 61F).

22. Check and install the dowel pins (23A) to

locate the case wear rings (23).

23. Place the rotating assembly into the pump

casing bottom half (B1). Correct any

excessive ‘O’ ring twisting or buckling. Check

that the impeller is centralised in the casing

and that there are no rubs.

24. Install casing gasket (1U) with a light coat of

commercial cup grease on both gasket

surfaces. Carefully align the inner edge of the

gasket with the insert ‘O’ rings.

25. Lower the upper half casing (Al) into place and

install casing joint nuts (1F).

26. NOTE: When installing upper half casing,

make sure that the ‘O’ rings (53R) are not cut

or pinched and that the gasket is hard against

the ‘O’ rings.

27. Insert casing joint dowels (1C) and drive them

home. Tighten the joint nuts (1F) to the

specified torques

Thread Size

lb/ft

Nm

M16

120

160

M20

260

360

M24

440

600

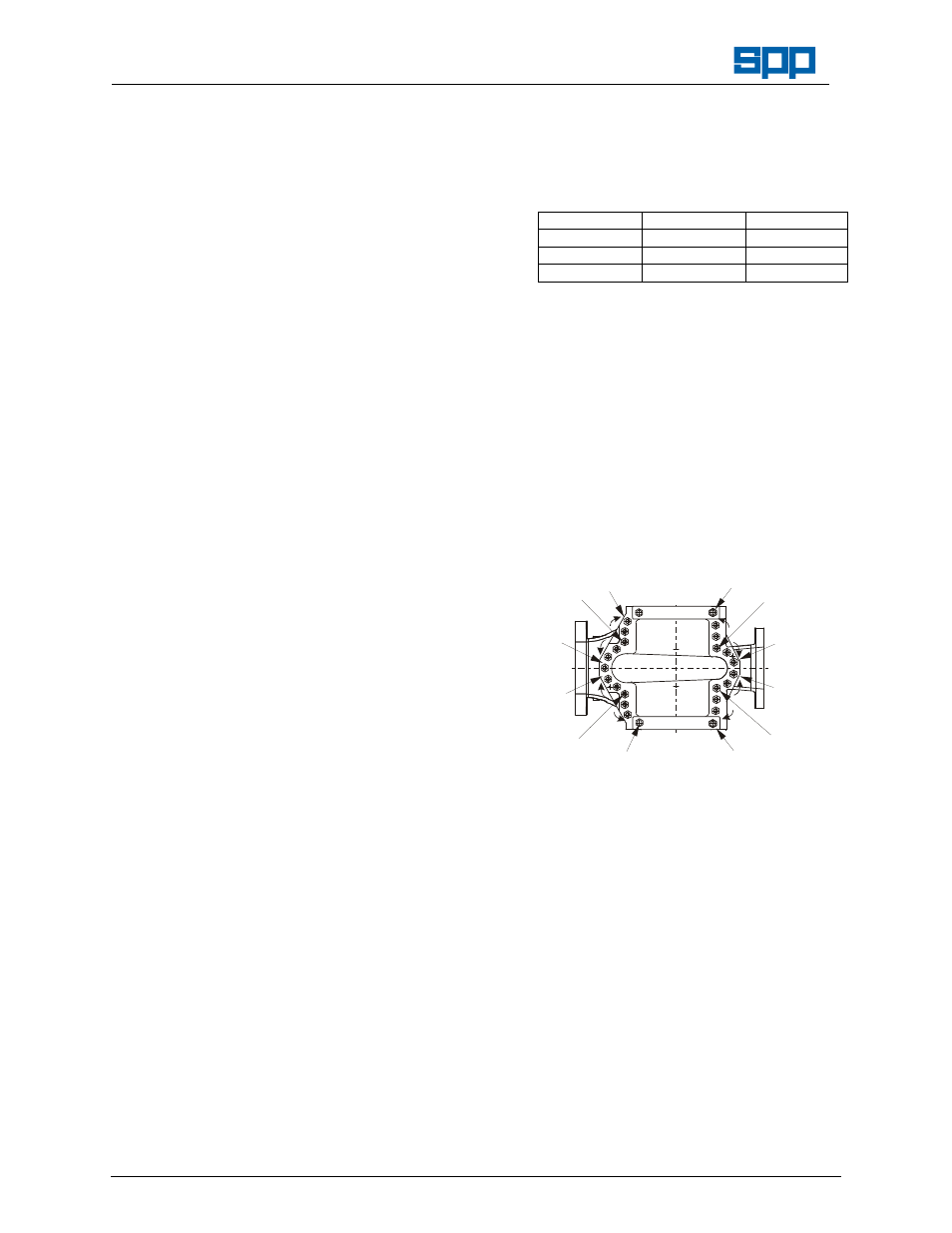

28. Tighten the case screws in the following

sequence:

a) Tighten the four 'corner' screws marked 1,

2, 3 and 4.

b) Work outward along shaft axis toward the

stuffing

boxes

in

opposite

quarters

tightening screws in regions 5, 6, 7 and 8.

c) Work outward along the branch and in

opposite quarters tightening screws in

regions 9, 10, 11 and 12.

d) Repeat the whole sequence (a to d).

1

2

3

4

6

8

7

5

9

10

11

12

29. Check that the shaft turns freely by hand.

30. Top up the bearing lubrication by applying

several strokes with a grease gun.

31. The pump is now ready for re-coupling to the

motor and re-commissioning.