SPP Pumps Thrustream User Manual

Page 15

Operators Instructions for Horizontal

Standard Thrustream Centrifugal Pumps

Manual No/Rev

W12-003E / 6

Our policy is one of continuous improvement and we reserve the right to alter specifications at any time

Page 15 of 28

Preparation for Removal of the Rotating Assembly

Disconnect the motor coupling.

For pumps fitted with mechanical seals, refer

to the seal manufacturer’s instructions and

lock the seal before removing the retaining

screws (52A) and sliding the seal back from

the face of the insert (A53).

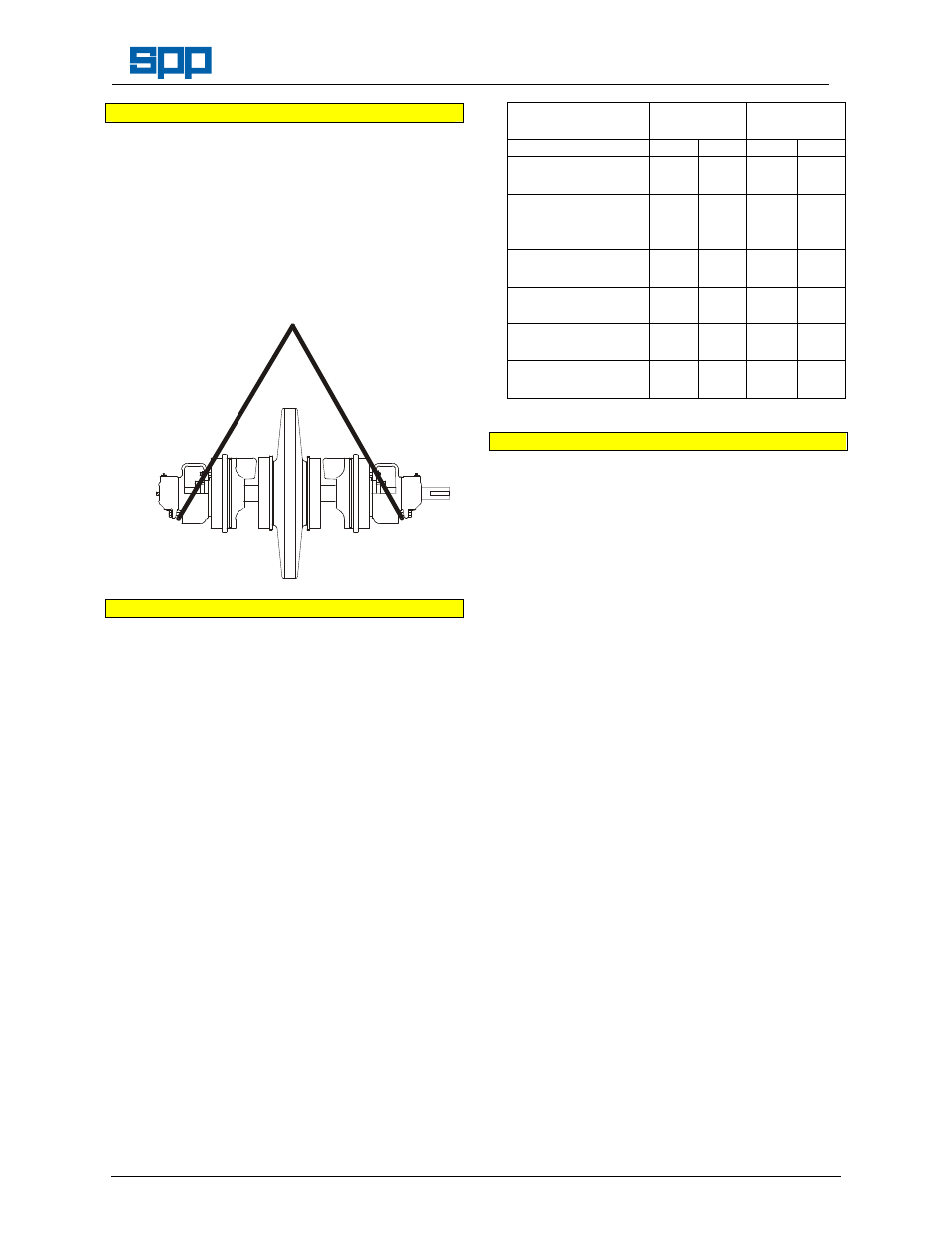

Provide a suitable lifting strap and support the

weight of the rotating assembly thus:

Removal of the Rotating Assembly Procedure

1.

Tap the inserts (53) with a soft-faced hammer

to break the seal between the insert and the

bottom half casing (B1).

2.

Lift the rotating element out of the bottom half

casing.

3.

Lift the rotating assembly clear of the bottom

half casing and support the shaft on suitable V

blocks with the impeller clear of the work

surface.

4

If necessary, remove the case wear ring

dowels (23A) from the bottom half casing

(B1).

5

With feeler gauges, check the clearance

between the case wear rings (23) and the

impellers (21), compare clearance with the

figures below.

Note Increase in the wear ring clearance allows

increased internal leakage with resultant loss

of pump performance, head and efficiency.

When the clearance is double the original

clearance, it is recommended that new wear

rings are fitted. It is permissible to run the

pump with increased clearance due to wear

but the loss of pump efficiency will significantly

increase the pump running costs.

Wear Ring

Clearance

Diametral

mm

Radial

mm

Pump Size :

Min

Max

Min

Max

65/24 80/24

80/30

0.180 0.302 0.090 0.151

50/38 80/38

125/29 100/30

100/24 100/38

0.210 0.350 0.105 0.175

125/24 150/24

125/30

0.230 0.370 0.115 0.185

150/30 125/38

150/38

0.240 0.401 0.120 0.200

150/48 250/24

200/30 250/30

0.260 0.421 0.130 0.210

200/38 250/38

200/48

0.280 0.441 0.240 0.220

Procedure to dismantle the Rotating Assembly

1.

Remove both bearing housings and bearings

as per the bearing replacement procedure

paragraphs 1 to 9.

2.

For soft packed pumps: Remove the nuts

(41C) and slide the glands (50) off the end of

the shaft (71) and remove the inserts (41 a &

B) complete with packing rings (51) and

lantern rings (46) and set aside for inspection.

3.

For pumps fitted with mechanical seals: Slide

the mechanical seal assemblies off the shaft

and set aside for inspection and remove the

inserts (41 A & B) complete with mechanical

seal (52) and throttle bush (45) and set aside

for inspection.

Impeller removal:

4.

If not already removed, remove the case wear

rings (23) and set aside for inspection and

measurement.

For Clockwise pump construction:

5.

Using a suitable ‘C’ spanner, unscrew and

remove the free - non-drive end sleeve (A47)

on a soft packed pump or free - impeller nut

(A21) on a pump fitted with mechanical seals.

Note Light tapping with a soft faced mallet may be

needed to free the impeller from the shaft, do

not damage the impeller if it is to be reused.

6.

Using suitable pullers or levers slide the

impeller (21) of the shaft (71) from the non-

drive end.

7.

Withdraw the impeller key (116) and unscrew

and remove the locked - drive end sleeve

(B47) on a soft packed pump or locked -