General description – SPP Pumps Thrustream User Manual

Page 5

Operators Instructions for Horizontal

Standard Thrustream Centrifugal Pumps

Manual No/Rev

W12-003E / 6

Our policy is one of continuous improvement and we reserve the right to alter specifications at any time

Page 5 of 28

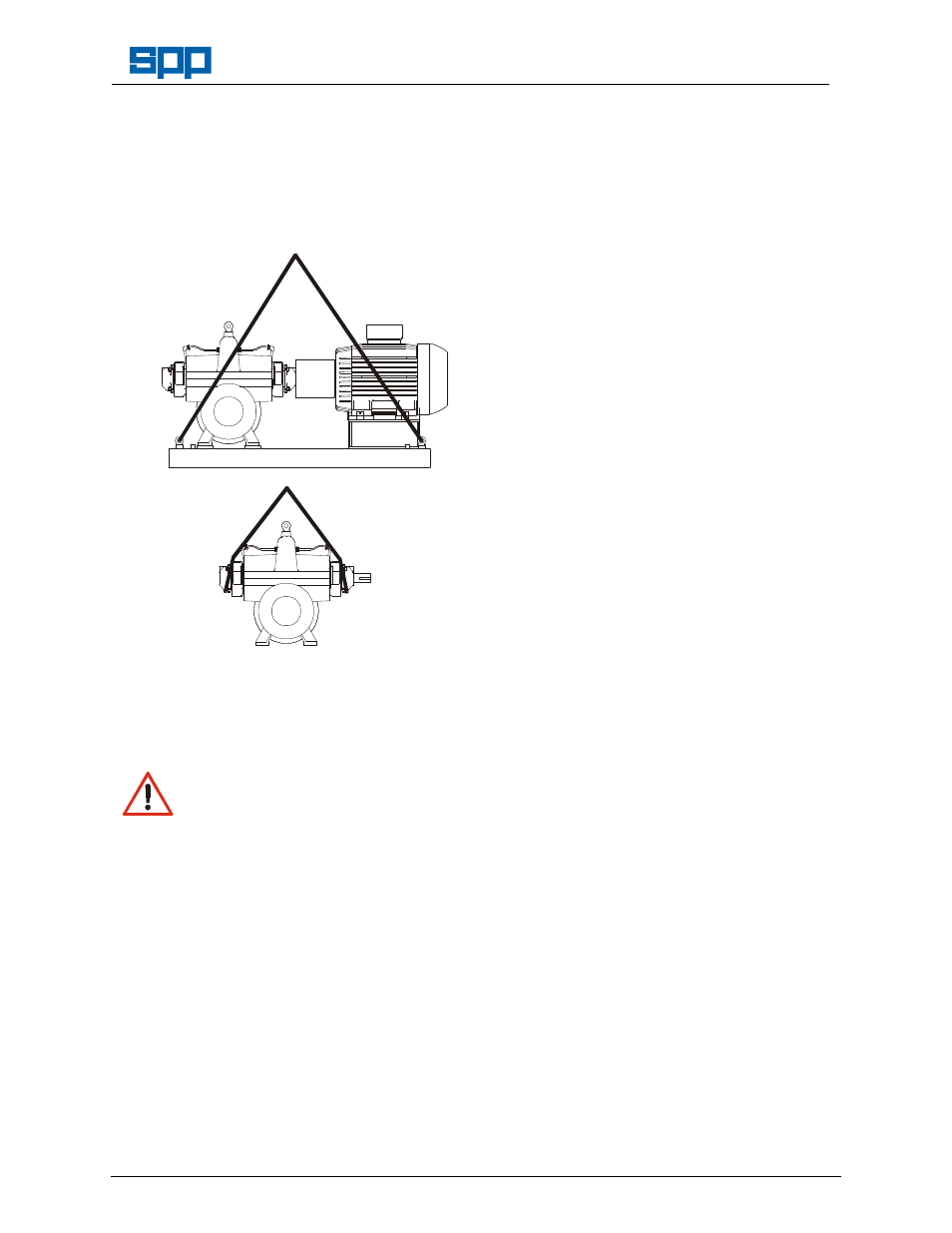

The use of suitable forklift truck and four-chain

crane sling equipment is recommended but

locally approved equipment of suitable rating

maybe used.

Pumps are usually supplied on pallets for

handling by forklift truck, to lift from the pallet

the pump should be slung as shown.

Pump weight is shown on the general

arrangement drawing supplied with each

pump or pumpset.

2.3

Storage

Shearing Hazard

Do NOT place fingers or hands etc. into

the suction or discharge pipe outlets and

do NOT touch the impeller. If rotated this

may cause severe injury. To prevent ingress

of any objects, retain the protection covers or

packaging in place until removal is necessary

for installation. If the packaging or suction and

discharge covers are removed for inspection

purposes, replace afterwards to protect the

pump and maintain safety.

2.3.1 Temporary Storage for up to Six Weeks

If the pump is not to be used immediately, it

should be stored carefully in a horizontal

position, in a sheltered, dry location. Additional

rust preventative should be applied to all

unpainted carbon steel or cast iron parts. Fit

or retain in place the covers to the suction and

discharge

flanges

and

all

other

pipe

connections. Rust preventative and flange

covers should not be removed until final

installation.

When pumps are not in use, the pump shaft

should be rotated several turns, every six

weeks.

2.3.2 Long Term Storage

It is recommended that the pump is stored in a

clean dry place that is not subject to a wide

temperature variation. Pack the bearings with

the specified grease and periodically inspect

the bearing housings to ensure that they are

free from damp and moisture. Leave the

covers for the suction and discharge flanges in

place or replace with suitable covers to

prevent ingress of dirt or moisture. Rotate the

shaft several turns monthly, to distribute the

grease and prevent pitting of bearing surfaces.

If storage in the open cannot be avoided,

cover the pump with a tarpaulin sheet, but

allow dry air to circulate around the pump.

For special protection of electric motors and

mechanical seals, refer to the manufacturer’s

instructions in Appendix l & III.

2.3.3 Exposed or Extreme Conditions Storage

For exposed storage or extreme variants in

atmospheric or environmental conditions,

please refer to SPP Pumps Ltd.

3. General Description

SPP Pumps Ltd. Thrustream Pumps are a

range of centrifugal pumps that are usually

supplied as pumpsets with electric motors but

can be supplied separately for customers to fit

to drivers of their own preference.

3.1.

Pumps

The mechanical assembly comprises a rigid

shaft, supported by grease-lubricated ball

bearings. The pump casing is fitted with wear

rings and normally contains a double entry

shrouded type impeller mounted on a stiff

shaft. Single side entry impellers are used for

two pumps in the range. The seal chamber is

housed in the casing inserts and these are

retained within the casing. Some impellers

may be fitted with wear rings if required.

When the top half casing is removed, the

bearing housings, inserts, shaft and impeller

assembly can be removed from the bottom

casing for maintenance without disconnection

of pipework.

The suction and discharge branch flanges are

positioned horizontally at 90 degrees to and

below the shaft centreline. The pump casings

allow for construction to suit different rotations.