SPP Pumps Thrustream User Manual

Page 12

Manual No/Rev

W12-003E / 6

Operators Instructions for Horizontal

Standard Thrustream Centrifugal Pumps

Our policy is one of continuous improvement and we reserve the right to alter specifications at any time

Page 12 of 28

45

o

Repacking Procedure

10 Insert the first ring and tap it to the bottom of

the stuffing box. Each following ring should be

installed in the same manner and positioned in

the stuffing box so that the "split" is advanced

120°.

11 Install the lantern ring (46) in its proper

position to align with the seal lubrication

connection, allowing for movement of the ring

deeper into the box as the packing is

compressed.

12. When the all the rings have been inserted, the

last packing ring should not protrude from the

stuffing box face.

13. Slide the gland into the stuffing box and

ensure that it sits squarely against the last

packing ring. Fit the gland retaining nuts and

washers (41C & 41G) on the studs and tighten

evenly to finger pressure.

14. Start the pump as per paragraph 5.2, allow

pressure to increase to normal level and

ensure that air is not trapped in the pump

casing.

15. A soft packed gland must have slight steady

leakage, and this should start soon after the

pump reaches it’s normal operating pressure.

16. If gland leakage stops, the pump will overheat

leading to seal damage or premature pump

failure. If overheating is detected, the pump

must be stopped and allowed to cool and

when restarted, gland leakage should start.

17. If the pump overheats again, stop the pump

restart it again, do not slacken the gland

retaining nuts.

18. After the pump had been running for 10

minutes with steady leakage, tighten the gland

nuts by one sixth of a full turn. Continue to

adjust at 10-minute intervals, each time

evenly, by one sixth of a full turn, until leakage

is reduced to an acceptable level (30 drops

per minute minimum).

19. Excessive gland pressure will cause damage

by cutting off lubrication to the packing, and

the packing will burn and damage the

shaft/sleeve.

6.3

Maintenance of Mechanical Seals

Generally no maintenance is required on

mechanical seals. They should be replaced if

leakage occurs but if maintenance is required,

the manufacturer's information is given in

Appendix IIl.

For disassembly and assembly instructions for

pumps

fitted

with

internal

component

mechanical seals, please refer to separate

instructions that can be obtained from SPP

Pumps Ltd.

6.4

Bearing Lubrication

The ball bearings are supplied pre-loaded with

appropriate grease. A grease nipple and seals

are fitted to the bearing housing to ensure that

any surplus grease is trapped inside the

bearing housing.

It is important to know the weight of grease

delivered by each stroke your grease gun to

ensure application of the correct amount of

grease.

It is recommended that the drive end bearings

are topped up as per the Recommended

Maintenance Schedule in Section 6.

Recommended Grease Lubricant:

International

Standard

DIN 51825:

KP2 K-30

As Supplied with

a new pump.

TEXACO MULTIFAK ALL

PURPOSE EP2

Note Greasing points may be provided for the

bearings on the electric motor fitted, refer to

Appendix I for motor maintenance details.

6.5

Bearing Replacement

Ball bearings will provide satisfactory service

for their designed working life if they are

correctly lubricated and inspected at the

intervals shown in Section 6. - Recommended

Maintenance Schedule.

Bearing Specifications

Pump Shaft

Module

Ball Bearing

Reference No.

Module 1

6306

Module 2

6309

Module 3

6312

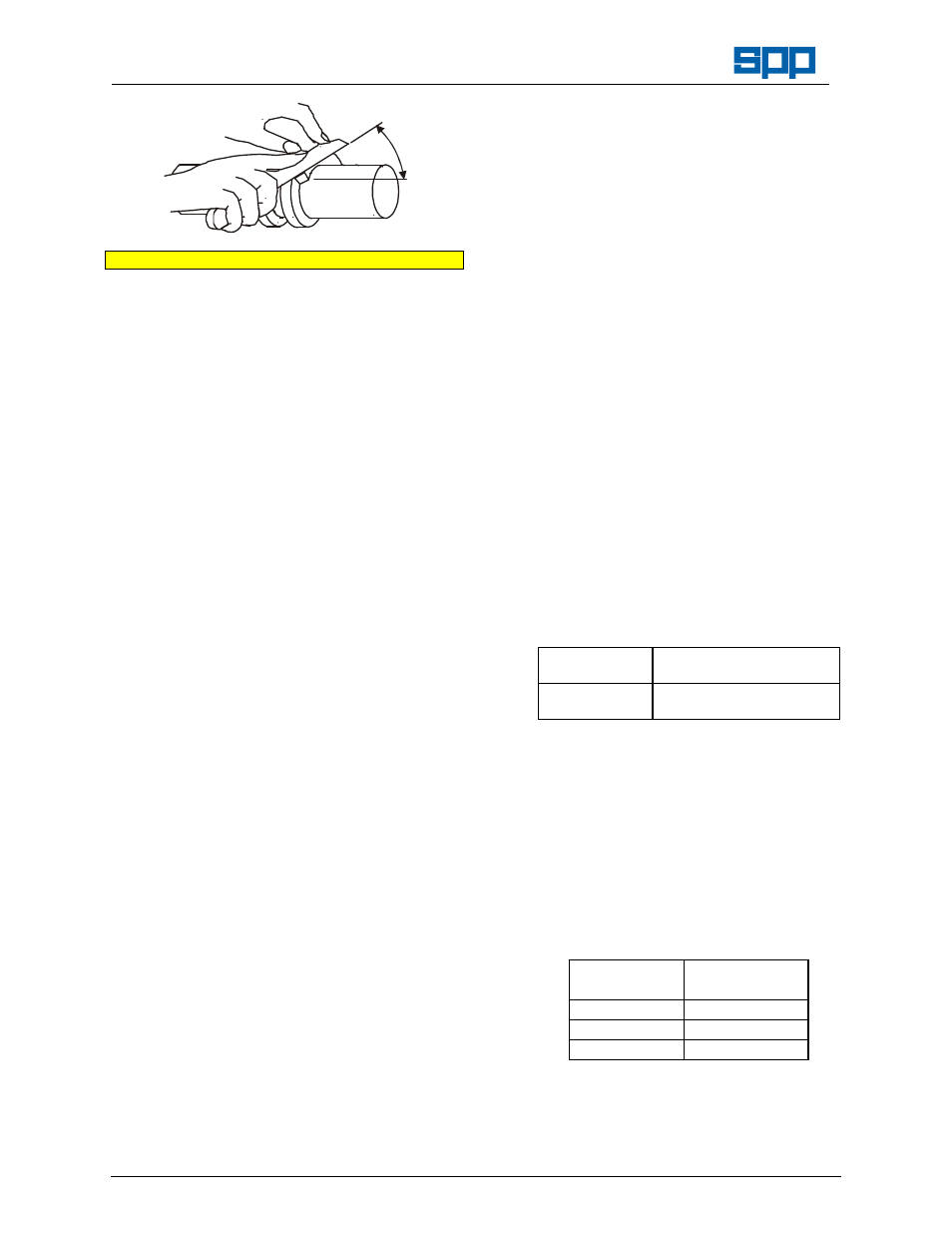

A suitable bearing puller is required for

removal of the bearings from the pump shaft.

If a puller is not available, a hammer and soft

metal drift may be used to tap evenly around

the circumference of the inner ring.