Installation, Install boiler trim – Fulton Reliance (RLN) High Efficiency Cooper Fin Boiler User Manual

Page 11

Questions? Call (315) 298-5121, or visit us online at www.fulton.com

SECTION 2

RLN-IOM-2012-1205

INSTALLATION

2-5

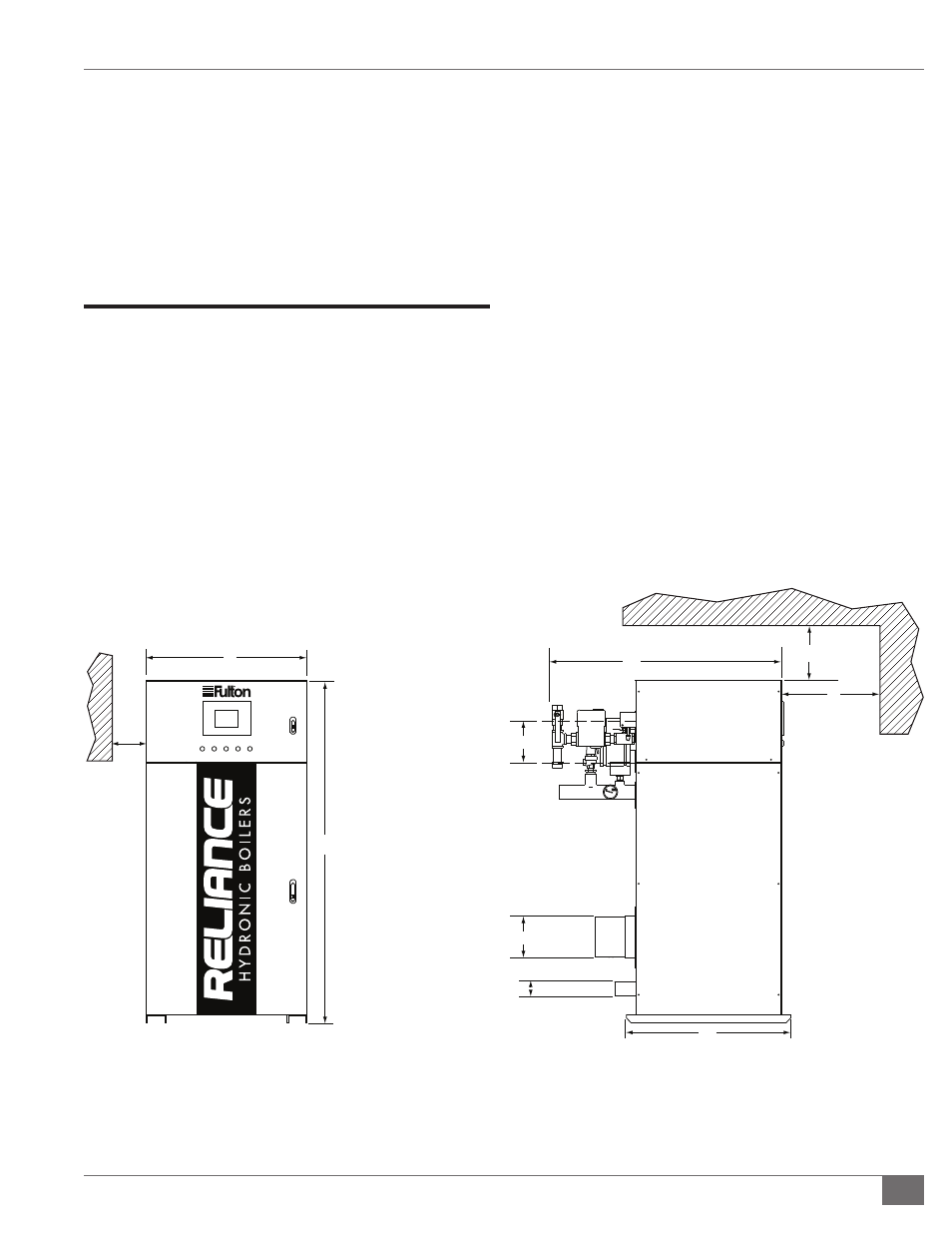

2. Appropriate front, back, side and top clearances must

be maintained (Figure 1). This will allow access around

the equipment to facilitate maintenance and a safe

work environment. An 1 inch (25.4 mm) side clearance

is acceptable between boilers.

3. Ensure all labels on the boiler will be fully visible for

maintenance and inspection.

Install Boiler Trim

Each Reliance boiler is supplied with a safety relief valve

sized in accordance with ASME requirements. Adhere to the

following installation requirements:

1. The safety relief valve (Figure 2) must:

» Be connected to the coupling located in the

top rear outlet section of the boiler.

» Be installed in the vertical position.

» Be installed with a 4 inch (101.6 mm) nipple

between the boiler and the safety valve.

NOTE: Safety relief valve size is determined by trim pressure

and is supplied in the trim kit along with appropriate bushing,

inlet and outlet sizes.

The discharge pipe must:

» Not have a diameter less than the full area of the

valve outlet.

» Be as short and straight as possible and so

arranged as to avoid undue stress on the valve.

» Be supported by means other than the safety

valve itself.

» Be piped to avoid danger of scalding personnel.

NOTE: Each boiler is equipped with a pressure-temperature

gauge to be installed in the outlet piping section of the boiler.

FIGURE 1 -RELIANCE HYDRONIC BOILER CLEARANCES (REFER TO TABLE 1B)

A

B

D

J

H

I

C

Front View

Right Side View

F

E

G