Perma pure llc – Perma Pure Mini-GASS User Manual

Page 31

31

Mini-GASS User Manual | Original Instructions

PERMA PURE LLC

Mini-GASS™ User’s Manual

Doc. #212: Revision: 00A

Page 31 of 32

APPENDIX F: Safety Interlock System

Control system safety interlock

The interlock system is present to provide an output signal that can be used internally to stop

sample flow via the optional internal sample pump. This system can also be used to provide an

external output to a PLC or other control/monitoring system so that the status of the Mini-GASS

can be monitored.

Two relays are used to perform this function:

• Low purge flow relay - A differential pressure switch across the purge air ports of the PD dryer

senses the flow of purge air and energizes this relay when flow is present. A minimum purge flow

rate of about 10 lpm is required. Below this flow, the alarm relay will de-energize.

• Low temperature relay – The CAL 3300 temperature controller has an alarm function that is used

to energize this relay when the system is operating at normal temperature. The actual point at

which a low temperature alarm is triggered is Set-point minus 5C. For instance, if the

temperature controller is set at 90C, the alarm relay will de-energize at 85C.

The interlock system is used in the Mini-GASS to control the optional internal sample pump by

simply supplying power to the sample pump motor via the alarm relays. Each of the relays is of a

DPDT or double pole double throw design. This just means that there are two sets of normally

open/normally closed (N.O./N.C.) contacts in each relay. One set of contacts is used internally and

one set of contacts is provided to allow connection to an external system.

• Refer the drawing MG-1228-04-12. Internally these relays are wired in series to supply power to

the sample pump. To accomplish this, switched line voltage (115,230VAC, Orange wire) is

supplied to the common (term. #5) connection of the low purge flow relay. From the normally

open (term. 3) connection of the low purge flow relay, a brown wire connects to the common

(term. #3) connection of the low temperature relay. From the normally open (term. #3)

connection of the low temperature relay, a gray wire connects to the sample pump. This allows

the pump to start only if both relays are energized.

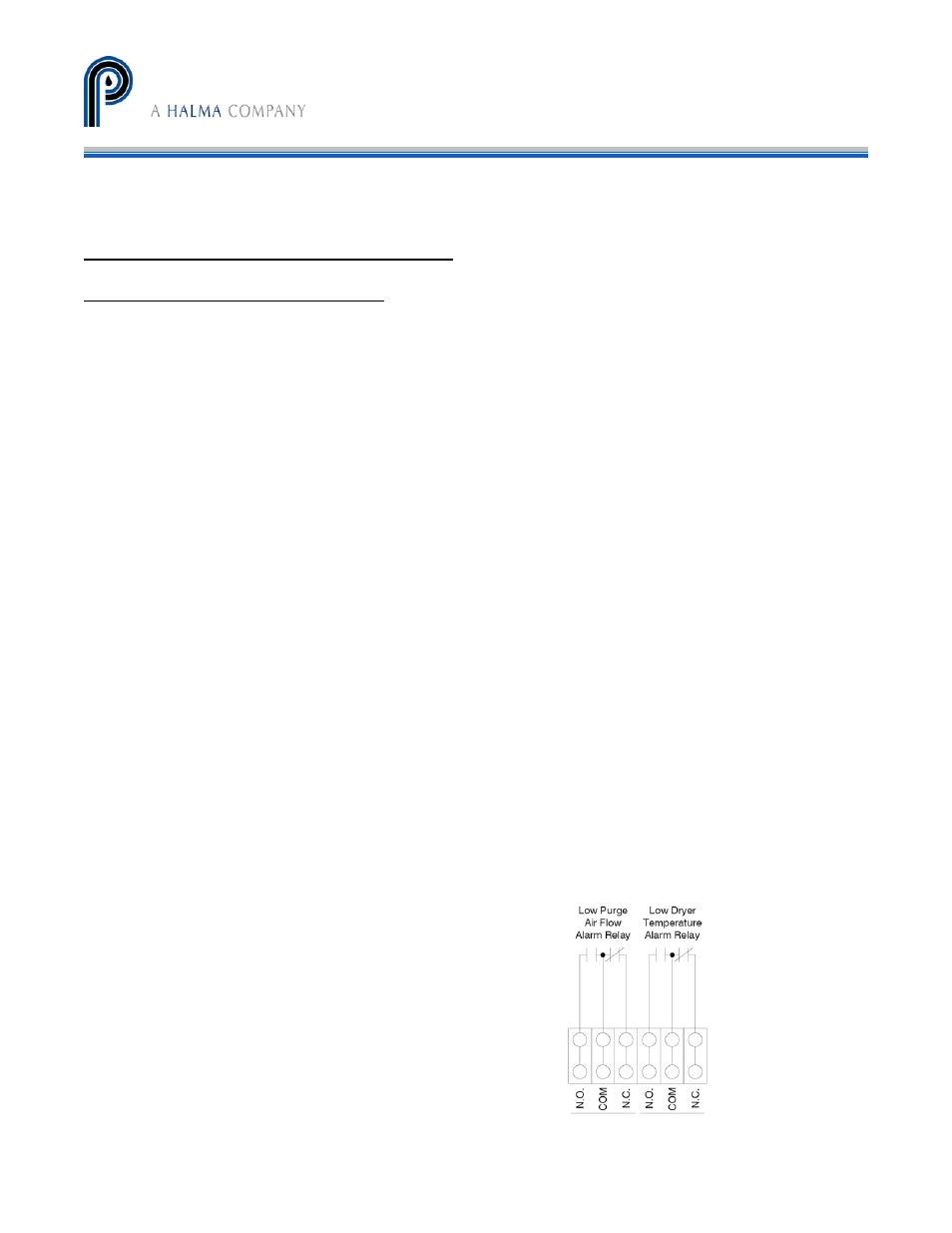

• Refer to Figure 20. For external connection, the second

set of contacts in each relay is “dry”. No power is

applied. This allows the user to determine the control

voltage that will be used. A typical use of the alarm

signal, as described above, is to control sample flow.

The actual use is left up to the customer.

Figure 20