Perma pure llc – Perma Pure Mini-GASS User Manual

Page 30

30

Mini-GASS User Manual | Original Instructions

PERMA PURE LLC

Mini-GASS™ User’s Manual

Doc. #212: Revision: 00A

Page 30 of 32

APPENDIX E: Z-Purge

Operation

With the inert gas supply connected, enclosure power de-energized and alarm system (if utilized).

Follow steps to purge system:

1. Carefully read Start-Up Instruction Nameplate on system.

2. Check operation of the Enclosure Protection Vent (EPV-1, if utilized), opening it manually

several times (see helpful hints below)

3. Seal protected enclosures.

4. Open Enclosure Pressure Control Regulator, but turning CW, to set Enclosure Pressure

Indicator at “Safe” pressure.

5. Ensure the Protection System Enclosure Pressure Indicator maintains a “Safe” pressure

for one minute.

6. Standby for exchange time as specified on the Instruction Nameplate, then energize the

protected enclosure power.

7. Ensure the Enclosure Pressure Indicator maintains a “Safe” pressure before leaving

system unattended.

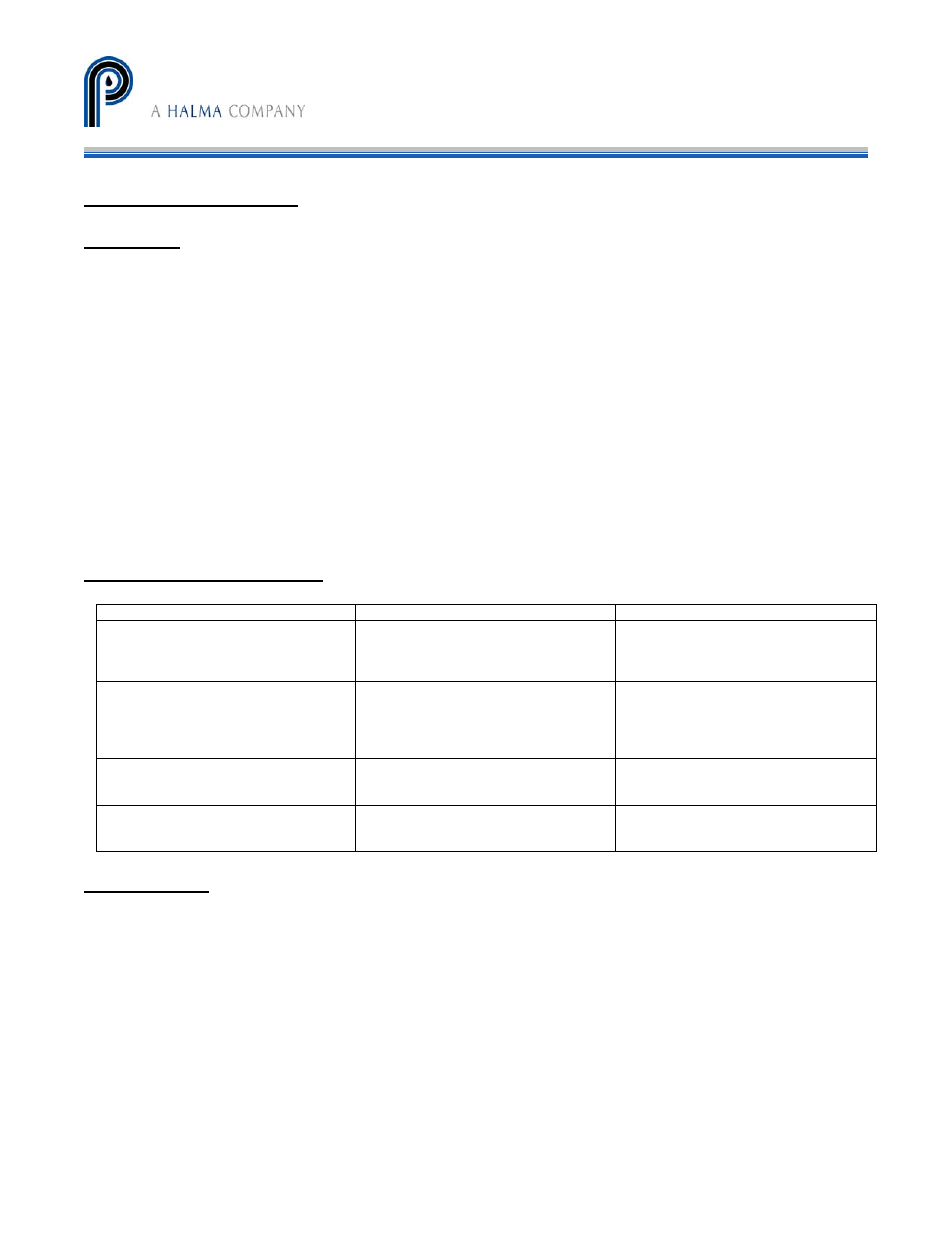

Z-Purge Troubleshooting

Problem or Fault

Possible Causes

Corrective Action

Enclosure pressure control regulator will

not hold a safe pressure.

Leakage around gasketing, covers,

seams, piping and tubing connections,

conduit connections and electrical

conduit seal of the enclosure.

Tighten enclosure latches: silicone

sealant can be applied from inside the

protected enclosure where tightening is

not feasible.

Enclosure pressure indicator reading is

difficult to stabilize.

In sufficient enclosure leakage or

opening of the venturi orifice is crimped

too small.

Remove the orifice, cut off crimped end

and ream tube, then recrimp and

reinstall tube. As tube is shortened,

sensitivity decreases allowing easier

setpoint on the enclosure.

Enclosure pressure Indicator “Drifts” up

or down from the “Safe” pressure setting.

Application involves a small, tightly

sealed enclosure and/or a fluctuating

protective gas supply.

Pre-regulate gas supply upstream of the

enclosure protection system to 5 psi

maximum.

Enclosure pressure loss alarm switch

does not appear to be operating.

Pressure switch is out of calibration.

Calibrate by slowly adjusting

counterclockwise to decrease setpoint

and clockwise to increase setpoint.

Helpful Hints

- The term “Safe” pressure for purposes of this manual is defined as follows:

Class I = a minimum 0.25 inch of water column pressure.

Class II = a minimum 1.0 inch of water column pressure.

- Regulator may be in the locked position upon arrival. To adjust regulator, pull handle to outward position.

- To test the vent’s operation, gently prod the vent flapper open with a soft pointed object (i.e. eraser end

of pencil) ensuring that the vent works freely.