Micromod MOD: 30ML and Modcell Totalization Application Guide User Manual

Page 7

Using The Totalizer Block

Description

5

used to increment a counter identifying how many times the totalizer has wrapped. The High

Limit Status line will reset to false on the next block execution if Auto Wrap is set to yes.

Threshold

Typically set at time of configuration. This is the value in engineering units by which the Analog

Input (totalizer input) must exceed before the totalizer will count. The purpose of this feature is to

ignore the counting of unwanted process or transmitter drift.

Command

The Command input is typically used with the MOD 30ML display block or when sending either a

Reset, Stop, Run or Hold command from a host such as a PC. Commands sent to this input are

long state data types and should be momentary. When the Command line is read from the

totalizer block it will always be 0. Sending the following long state values to the Commands input

causes the following associated action to happen.

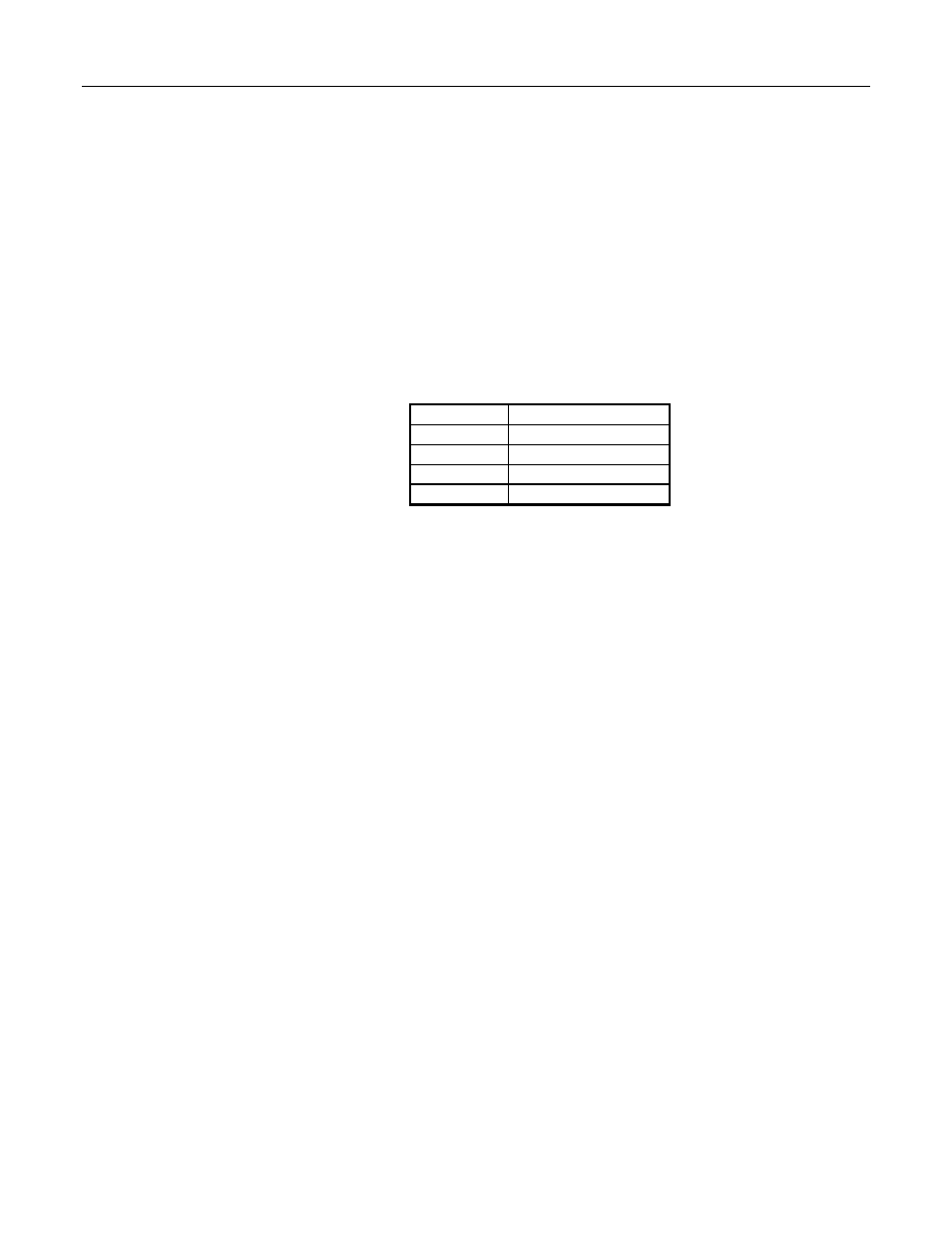

Value

Action

1

Reset

2

Stop

3

Run

4

Hold

Restart Mode

Typically set at time of configuration. This is the mode of the totalizer block when the instrument

is initialized after a cold or frozen restart and the controller is set to hold. For example: If the

warm start period is set for 30 minutes (warm start parameter is set in the IF Block) and the

Restart Mode of the Totalizer block is set for Hold and then power is lost, if the power is restored

after 30 minutes the block will come back in the Hold mode. If the power down time is less than

30 minutes the totalizer will resume with the mode prior to power loss.

Predetermined Count 1 & 2

The predetermined count value is set at configuration time. When the totalized value is equal to

or greater than the predetermined value its associated Predetermined Status line will be set to

true. If counting down and requiring a status true when the count is below the predetermined

value, invert the status signal in an Expression block. An example of where to use a

predetermined count is in a ratio application to cause valve closure at a particular totalized value

while continuing to totalize other ingredients which may still be flowing. Two predetermined count

values are provided in case multiple points are needed.

Rate

Typically set at time of configuration. This is the time units used in interpreting the input value.

Rate may be determined as either Seconds, Minutes, Hours or Days. Rate only applies when the

Input Type is Analog (not with Pulse). For example: If an inputs engineering units are 0 - 100 and

the Rate was set at Minutes, with 100% input there would be a count of 100 at the end of one

minute. Note: this calculation is affected by the Scale Factor.

Scale Factor

Typically set at time of configuration. This feature permits custom scaling of a totalized count. A

Scale Factor of 1 causes an unaffected count. A Scale Factor of 10 divides the total by 10 and a

Scale Factor of 0.1 multiplies the total by 10. For example: In our above example, if an inputs

engineering units were set at 0 - 100, the Rate was set at Minutes and the Scale Factor was set

at 0.1 then, with 100% input there would be a count of 1000 at the end of one minute.