Operation piping diagram – Max Machinery G240 Gear Flow Meter User Manual

Page 11

Max Machinery, Inc. G Series User Manual © Copyright 2013

Rev. 001Q4

Determine that the following parameters of your flow metering system are within the specifications for the specific

meter being used:

Maximum System Pressure (Specifications)

Differential Pressure across meter (Pressure Drop Curves)

Maximum Flow Rate (Pressure Drop Curves)

Metered Fluid Temperature (Sales specification, transmitter specifications page 8)

If the metered fluid is a solid at room temperature, it is critical that it be fully melted before applying pressure to the

meter in order to avoid excessive loading on the bearings or potentially fracturing the sensor magnet. To determine melt

times, measure the surface temperature as near as possible to the transmitter. Wait until the body temperature exceeds

the melting point, allowing additional time if the fluid is a poor heat conductor.

Starting with the valving to the flow meter closed, slowly open the bypass valve to establish flow.

Then slowly open the inlet and outlet valves at the flow meter. When the meter turns smoothly and you detect a flow

signal, slowly close the bypass valve completely.

If a bypass valve was not installed in the system, initiate flow in the system as gradually as possible.

If you do not generate a flow signal, or the line pressure increases, stop the pump and allow more

time for the material in the meter to liquefy.

No routine maintenance, cleaning, or lubrication of the flow meter is required. A routine filter cleaning schedule should

be established. The system should be shut down if abnormal noises occur if unusual differential pressures across the

meter are encountered.

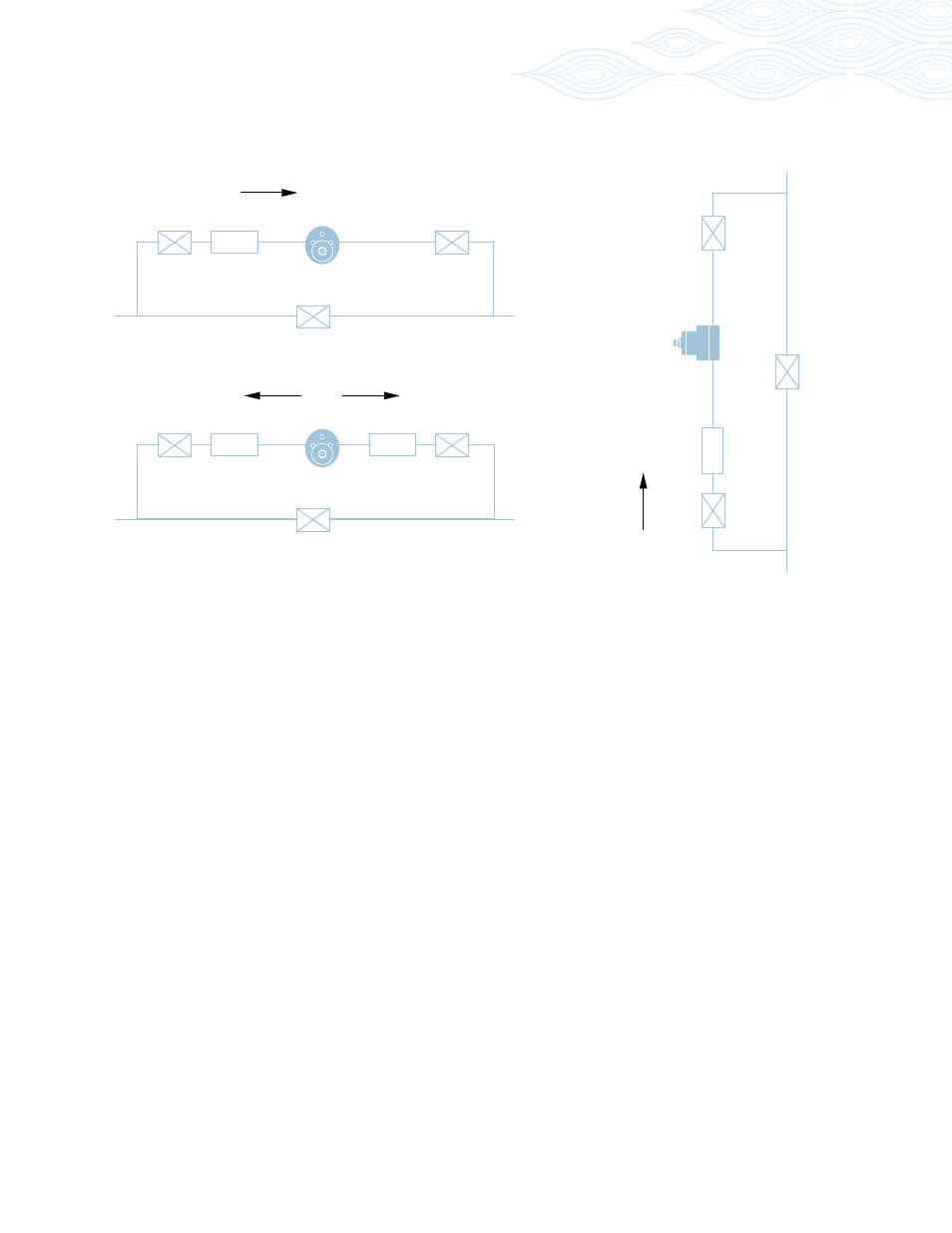

Operation

Piping Diagram

FILTER

VALVE 2

VALVE 1

FLOW METER

VALVE 3

FLOW

BYPASS

FILTER

VALVE 2

VALVE 1

FLOW METER

VALVE 3

FLOW

BYPASS

FILTER

FILTER

VALVE 1

VALVE 2

FLOW METER

VALVE 3

FLOW

BYPASS

Horizontal Installation

Horizontal Two-Way Flow

Vertical Installation