Mallory Ignition Mallory HYFIRE VII Series Electronic Ignition Controls 667C User Manual

Page 6

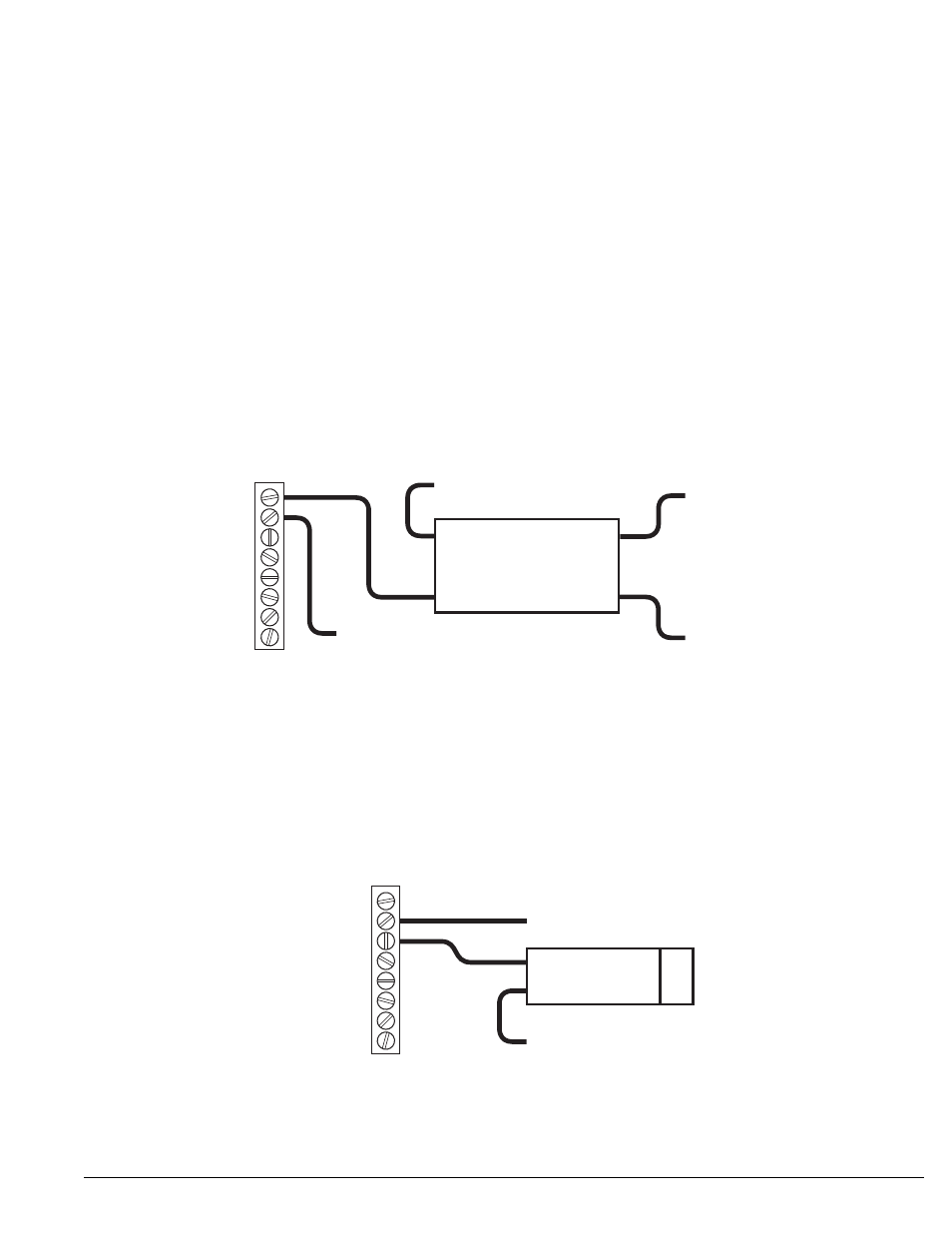

NC

C

NO

RPM2

RPM3

RET1

RET2

RET3

COIL

COIL

CONTACT

CONTACT

To Ground

To +12 Volts

To Nitrous System

From Nitrous

Activation Switch

RELAY

Use a relay if you are

switching more than 3-5 amps.

EXAMPLE 1: Using the RPM switch (Mode 7) to turn OFF

a nitrous system at a particular RPM.

NC

C

NO

RPM2

RPM3

RET1

RET2

RET3

To +12 Volts

To Ground

EXAMPLE 2: Using the RPM switch (Mode 7)

to turn on a shift light.

Additional Functions:

The HYFIRE

®

667C has two more functions that can make the ignition instal-

lation and setup work better. One of these is the high-speed advance function.

This lets you put small amounts of timing in the engine after the torque peak

to pick up a bit of horsepower. There are three things that need to be set up

for this: the cut-in RPM (mode 9), the maximum advance (mode A), and the

slope (mode 8). The cut-in RPM is the RPM where you want the curve to start

working. The slope is how much the timing will advance every 1000 RPM

after the cut-in RPM. The maximum advance is the highest amount of

advance you want the system to reach.

For example, say that your engine has the torque peak at 6500 RPM, and you

want to add some timing after this. You might want to start adding timing

after 7000 RPM, so this becomes your cut-in speed. If you then want 2

degrees additional timing at 8000 RPM, then the slope would be set for 2

degrees per 1000 RPM. However, let's say that you don't want more than 2

degrees of advance, so you would set the maximum advance at 2 degrees.

See example 7 for more detail.

The other additional function available is trigger compensation, which is set

when the mode indicator is "b". This lets you compensate for the various

delays in ignition timing caused by both electronic and mechanical changes.

To set the trigger compensation, set mode 9 to 5000 RPM, and mode 8 to

zero. What this does is tell the system to start the high-speed advance at 5000

RPM, but with a slope of zero, there should be no advance. Once the system

is set up this way, watch the timing as the engine revs past 5000 RPM. If the

timing does not stay at a steady value (once the 5000 RPM point is reached)

then adjust the compensation value until it is as flat as possible. For example,

if the timing retards slightly as the RPM goes up, increase the compensation

value. If the timing advances slightly as the RPM goes up, decrease the com-

pensation value. NOTE: This function is only valid for RPM above the high-

speed advance cut-in RPM. If you have the high-speed advance cut-in set

above the normal operational range of the motor, the compensation func-

tion does nothing.

Once the compensation is set, then the high speed advance settings will be

accurate. The factory setting should be correct for most types of flying mag-

net type crank trigger systems, and should not normally need to be adjusted

unless you are using a different trigger type.

Number of cylinders selection

The final mode that can be set is mode "C". This allows you to select 4 through

12 cylinder operation. This ensures that the RPML and the timing are proper for

the engine. Mode 6F is special - this is for odd-fire V6 engines ONLY! The cylin-

der firing spacing should be 45/75 (at the distributor) or 90/150 at the crank.

Mallory-Ignition.com

5