Magnum Venus Plastech PVSensor User Manual

Page 3

PVSensor Instruction Manual. Issue-08 25/06/2008 Page 3 of 8

OPERATING THE PVSENSOR:

The resin pressure within the mould will be continuously monitored and once the set-point has

been reached a green LED will illuminate on the left hand side of the unit. This also provides a

signal to the Machine Control solenoid valve mounted within the machine.

This signal will reduce the flow of resin to the mould by slowing the machine, or stopping it all

together, so that the mould’s internal pressure does not exceed the set-point. Once the pressure

drops back the machine will automatically speed up, or start again.

Once the set-point has been reached and the solenoid energized to stop the machine (LED on),

the pressure must fall by a given amount (Hysterisis) before the unit restarts the machine. This

prevents the system from continuously starting and stopping the machine as the mould pressure

moves around the set-point (hunting). The Hysterisis is factory set and should not be adjusted

under normal circumstances.

POSITIONING AND FITTING THE SENSOR IN THE MOULD:

In LRTM moulds, the Sensor should be positioned in the resin feed channel using a mould insert

that is positioned between 300mm and 600mm from the resin input point.

For infusion applications this should be between 100mm and 200mm. If the PVS unit is to be

used solely to sense the mould pressure and not to control the machine, then the Sensor can be

sited anywhere in the mould using the Film Infusion Extension option # 5885.

It is important that the Sensor’s mould insert is installed in a vertical, or near to vertical position on

the mould’s upper (back) tool. NOTE: The Sensor is not designed to work if it is installed off

vertical by more than 30º and must not be installed, or used, inverted.

NOTE:

Injection Autosprue positioned

in the peripheral resin feed

channel.

The PVSensor positioned no

more than 600mm away from

the injection point.

PVSensor mounted vertically on upper (back) LRTM tool.

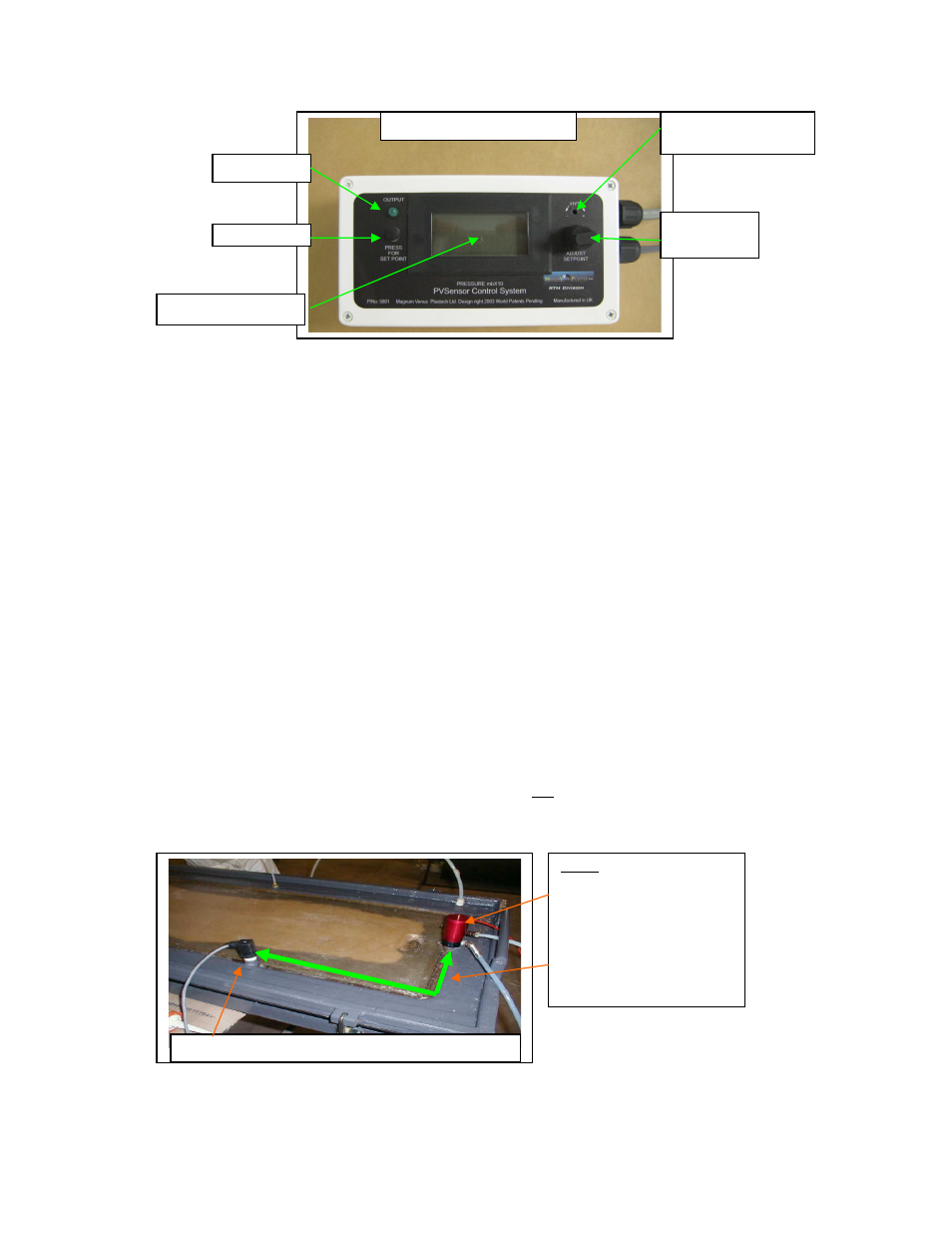

Set-point

adjustment

Green LED

Press to set

LCD Display x 10mb

Hysterisis Adjustment

– use Trimmer tool

Electronic Module Controls