Magnum Venus Plastech PVSensor User Manual

Pvsensor

PVSensor Instruction Manual. Issue-08 25/06/2008 Page 1 of 8

PVSensor

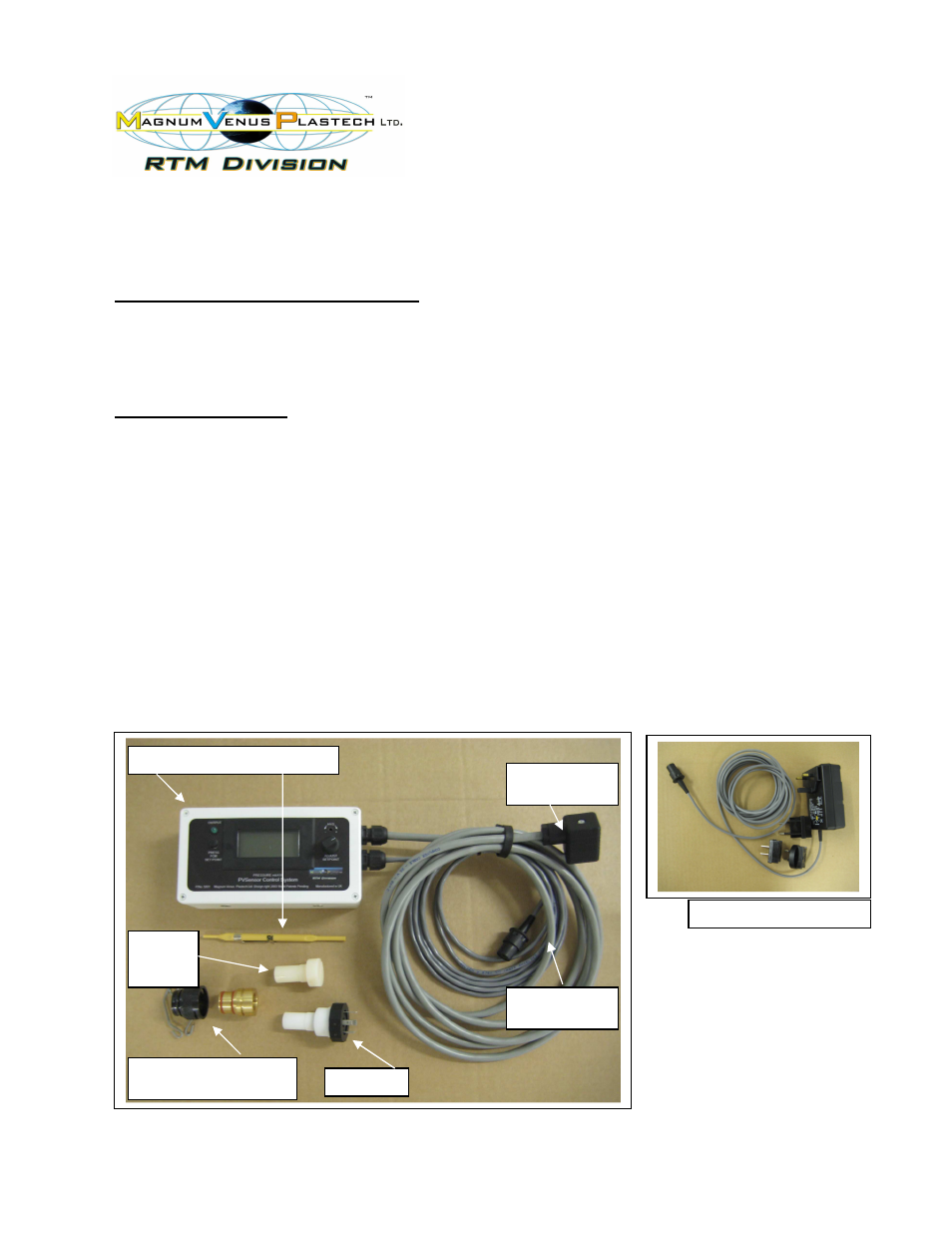

Complete System # 5801

Procedure for Installation and Use

The PVSensor (PVS) system is designed to safely optimise LRTM or RTM mould fill. It is now possible to

monitor and control the in-mould pressure from 800mb to 2000mb. (The short term, safe over-pressure is

rated at 3 bar).

The system comprises:

•

Electronic Display Module # 5798 – Operator controls and status LED

•

Power Supply Unit # 5799 - 240/110vAC input, 12vDC output

•

PVSensor # 5797 - A PTFE bodied precision electronic pressure sensor to fit a mould insert.

•

Machine Control # 5789 - Output solenoid to control the resin flow of meter mix machinery.

Kit contains complete mounting bracket set and conversion fittings for Patriot SSB and

Megaject MkIV / MkV machines.

•

Universal Insert with spring Clip # 6316, and Adapter # 6317

ELECTRONIC DISPLAY MODULE AND POWER PACK:

The Electronic Module houses the circuitry that manages the signal from the PVSensor and allows the

setting of the required mould pressure set-point and hysterisis. It also provides Actual Pressure readings

from the sensor in the mb range. The scale is x 10, as individual millibar changes would be too rapid and

confusing to read. Therefore a reading of 101 is actually 1010 mb (101 x 10).

PVSensor

PVSensor

Socket

Universal Mould

Insert,

Spring Clip and adapter

PVS

Dummy

Plug

Electronic Module & Trimmer tool

Machine control

lead

Power Supply Unit ( PSU )